A mixed heat-not-burn shredded tobacco, its preparation method and application

A heat-not-burn, hybrid technology, applied in the field of tobacco silk making, achieves the effects of simple preparation method, mellow taste, and rich and satisfying smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

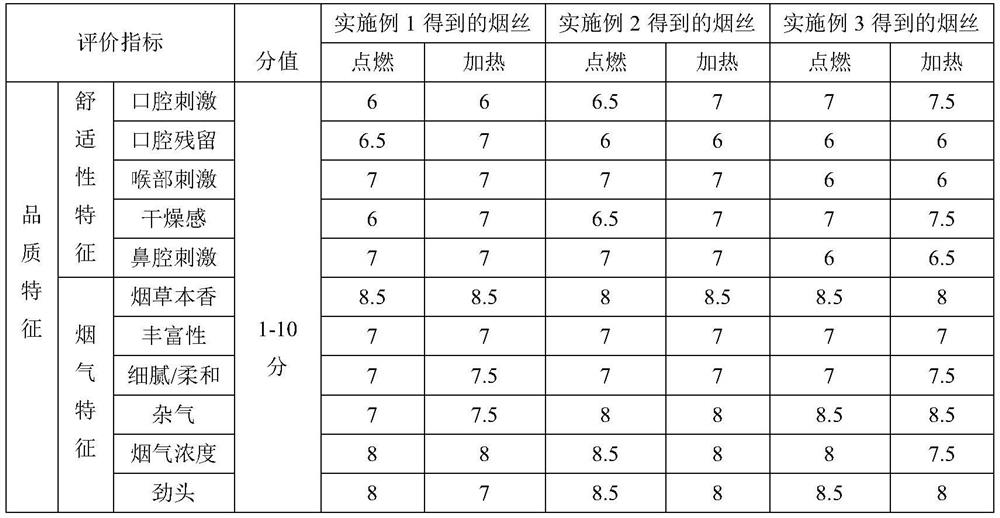

Examples

Embodiment 1

[0019] The mixed heat-not-burn shredded tobacco of this embodiment includes, in parts by weight, 40 parts of reconstituted shredded tobacco, 15 parts of burley shredded tobacco, 15 parts of flue-cured shredded tobacco, 15 parts of air-dried shredded tobacco, 10 parts of spiced shredded tobacco, and 5 parts of smoking components . The smoking ingredient is glycerol.

[0020] The preparation steps are as follows: mixing the above-mentioned shredded reconstituted tobacco leaves, shredded burley tobacco, shredded flue-cured tobacco, shredded air-dried tobacco and shredded flavored tobacco according to parts by weight, then adding smoking components and mixing evenly to obtain the mixed shredded heat-not-burn tobacco.

[0021] Wherein the preparation steps of the reconstituted shredded tobacco leaves are as follows: the reconstituted tobacco leaves are dampened, added with smoking components, shredded, dried at low temperature, cooled and dehydrated at low humidity to obtain the sh...

Embodiment 2

[0023] The mixed heat-not-burn shredded tobacco of this embodiment includes, in parts by weight, 45 parts of reconstituted shredded tobacco, 15 parts of burley shredded tobacco, 12 parts of flue-cured shredded tobacco, 10 parts of air-dried shredded tobacco, 10 parts of spiced shredded tobacco, and 8 parts of smoking components . The smoking ingredient is propylene glycol.

[0024] The preparation steps are the same as in Example 1. Among them, the smoking component of reconstituted shredded tobacco is propylene glycol, and the addition amount is 3% of the weight of reconstituted tobacco leaves; the low-temperature drying means that the shredded tobacco is dried at a temperature of 70°C; the low-humidity cooling and dehydration step is: firstly, the air is kept below 1°C Dehumidification is carried out so that the relative humidity is 8%, and then the shredded tobacco is cooled and dehydrated at 45° C. by using the dehumidified air to obtain the shredded reconstituted tobacco...

Embodiment 3

[0026] The mixed heat-not-burn shredded tobacco of this embodiment includes, in parts by weight, 35 parts of reconstituted shredded tobacco, 10 parts of burley shredded tobacco, 25 parts of flue-cured shredded tobacco, 20 parts of air-dried shredded tobacco, 10 parts of spiced shredded tobacco, and 10 parts of smoking components. share. The smoking ingredient is sorbitol.

[0027] The preparation steps are the same as in Example 1. The smoking component of the reconstituted shredded tobacco leaves is sorbitol, and the addition amount is 5% of the weight of the reconstituted tobacco leaves; the low-temperature drying is that the shredded tobacco is dried at a temperature of 80°C; the low-humidity cooling and dehydration steps are: Dehumidification is carried out at a temperature of 10% so that the relative humidity is 10%, and then the shredded tobacco is cooled and dehydrated at a temperature of 50°C by using the dehumidified air to obtain the shredded reconstituted tobacco l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com