High-aroma oolong black tea and making method thereof

A technology of oolong black tea and a production method, which is applied in the direction of tea treatment before extraction, etc., can solve the problems of weak taste and insufficient aroma of oolong black tea, and achieve the effects of mellow taste, fine shape, strong fragrance and floral fragrance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

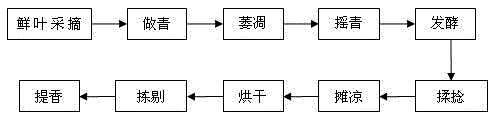

[0035] Embodiment 1: A method for making high-flavor oolong black tea is carried out according to the following steps: (1) Picking: pick the fresh leaves of tea trees from 11:00 noon to 4:00 pm on sunny days, and send them for greening every 0.5 hours; (2) Greening: Under the sun at 22°C, manually turn greening for 4 hours, turning it manually every 30 minutes; (3) Withering: Put the leaves into the withering room and wither at a constant temperature of 18°C for 8 hours. The air speed in the withering room is uniform and dehumidified, and the air humidity is controlled at 60%; (4) Shaking green: two times, first shaking the green for 20 minutes for the first time, and controlling the speed of the shaking machine at 4~5 rpm , then cool the greens for 1.5 hours, spread the thickness of 0.2~0.5cm, then shake the greens for the second time for 60 minutes, and control the speed of the shaker at 7~8 rpm; (5) Fermentation: stack the leaves at a height of 30cm And cover it with whit...

Embodiment 2

[0036] Embodiment 2: A method for making high-flavor oolong black tea is carried out according to the following steps: (1) Picking: pick the fresh leaves of tea trees from 11:00 noon to 4:00 pm on sunny days, and send them for greening every hour; (2) Greening: Under the sun at 25°C, do greening by hand for 3.5 hours, and turn it manually every 25 minutes; (3) Withering: Send the leaves into the withering room and wither at a constant temperature of 20°C~22°C7 Hours, the circulation wind speed in the withering room is uniform and dehumidified, and the air humidity is controlled at 55%; (4) Shaking green: two times, first shaking the green for 20 to 30 minutes, the speed of the shaking machine is controlled at 3 ~5 rpm, then cool the greens for 1.5~2 hours, spread the thickness of 0.2~0.5cm, then shake the greens for the second time for 50 minutes, and control the speed of the shaker at 7~9 rpm; (5) Fermentation: Stack the leaves 40cm high and cover them with white cotton cloth...

Embodiment 3

[0037]Embodiment 3: A kind of preparation method of high-flavor oolong black tea is carried out according to the following steps: (1) picking: pick the fresh leaves of tea trees from 11:00 noon to 4:00 pm on sunny days, and send them for greening every 40 to 50 minutes ; (2) Greening: Under the sun at 26°C, greening is done by hand for 3 hours, manually turned every 20 minutes; (3) Withering: Leaves are sent to the withering room for 6 hours at a constant temperature of 23°C , the withering indoor circulation wind speed is uniform and dehumidified, and the air humidity is controlled at 50%; (4) Shaking green: two times, first shaking the green for 30 minutes, the speed of the shaking machine is controlled at 3~4 rpm Minutes, then cool the greens for 2 hours, spread the thickness of 0.2~0.5cm, then shake the greens for the second time for 40 minutes, the speed of the shaker is controlled at 9~10 rpm; (5) Fermentation: stack the leaves 50cm High and covered with white cotton clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com