Anti-blocking automatic rotary sieve tray

A technology of feeding equipment and automatic rotation, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of not having accelerated screening, unfavorable fast production, weak prevention of clogging, etc., to increase the screening function and avoid bad Influence, enhance the effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

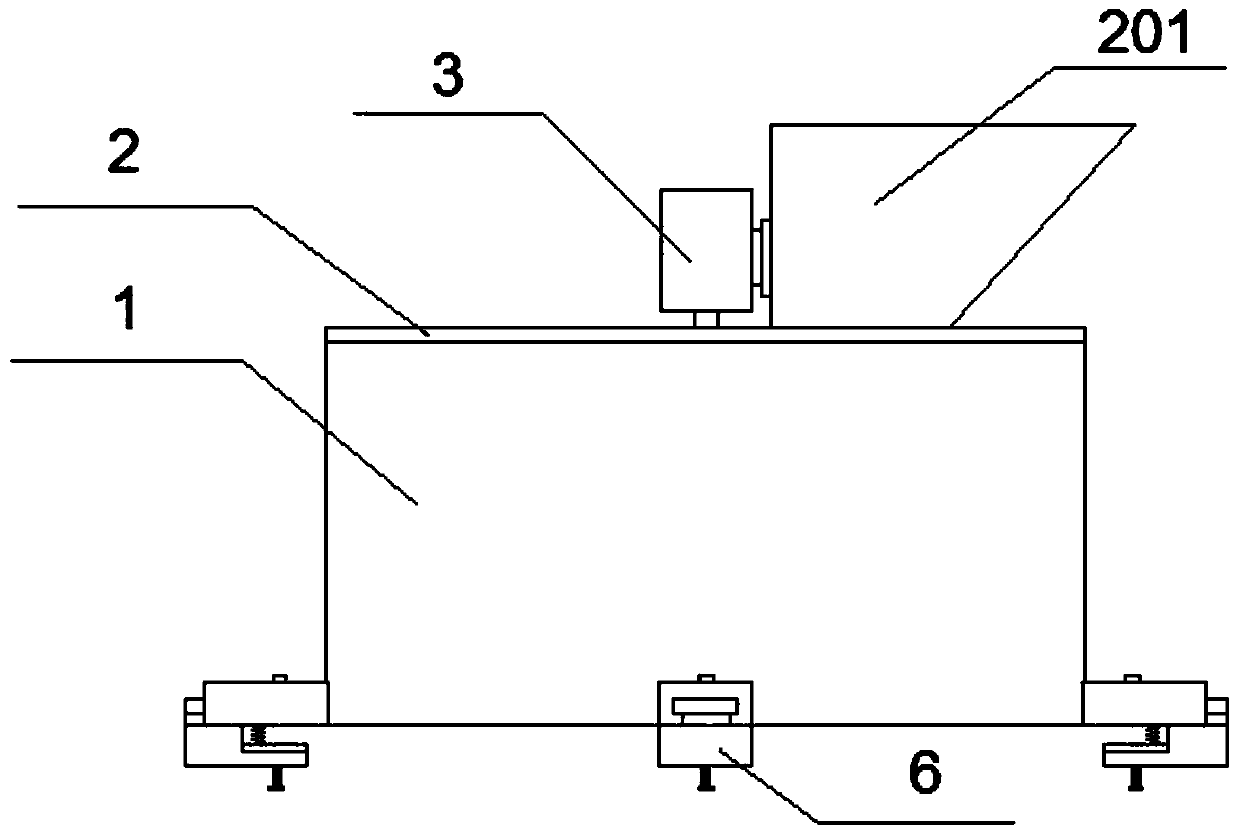

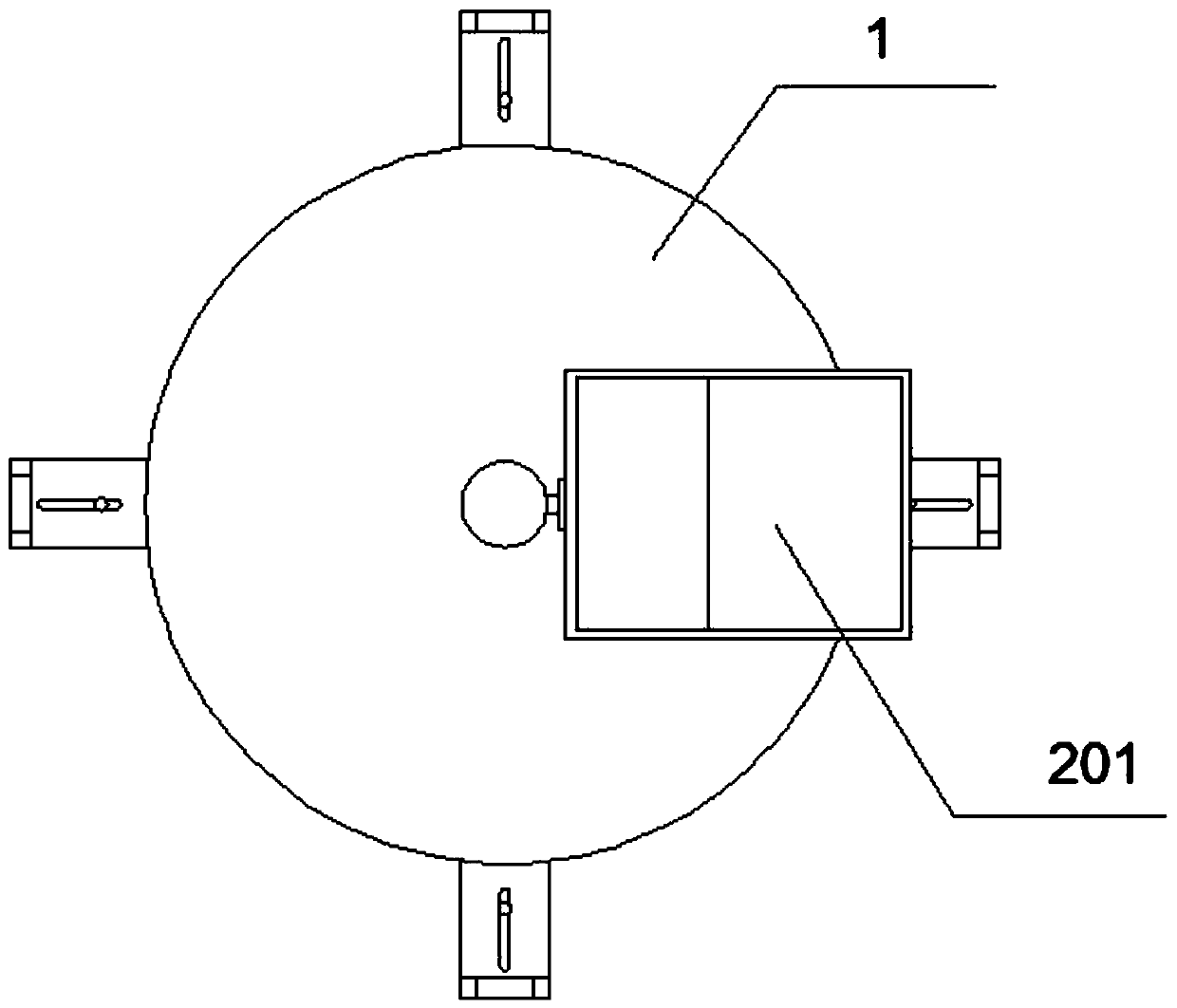

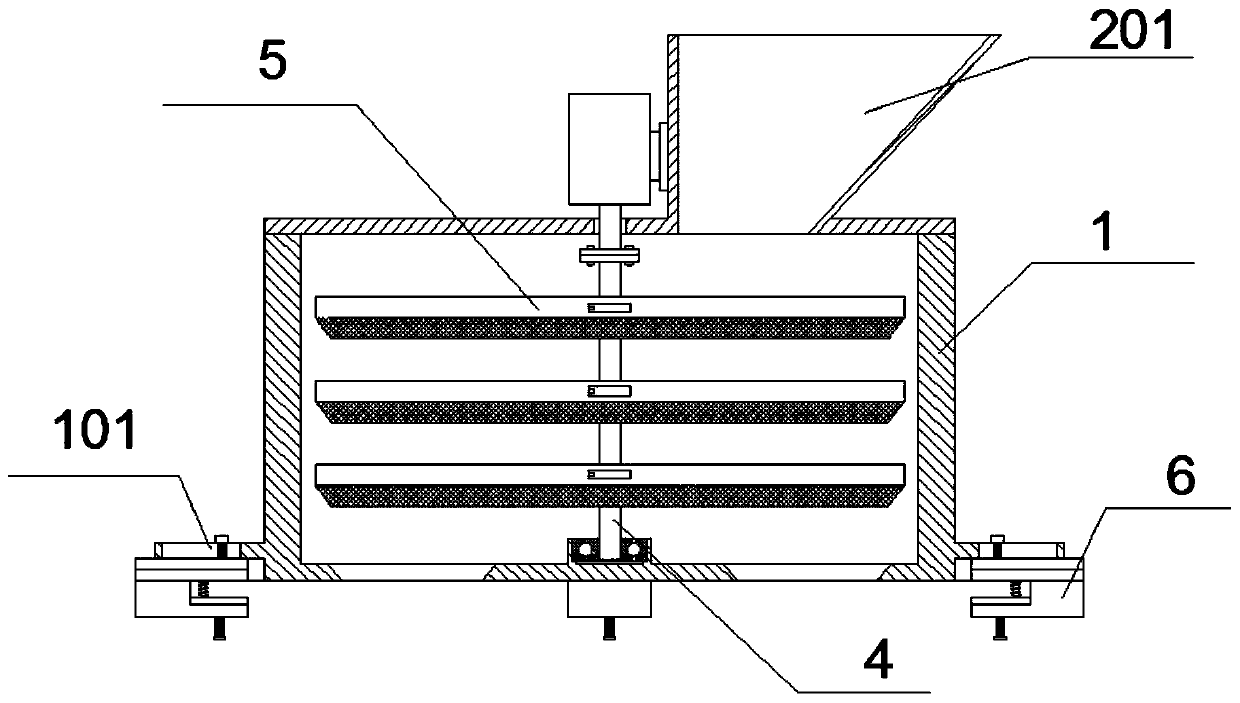

[0027] as attached figure 1 To attach Figure 6 Shown:

[0028] The present invention provides an anti-clogging automatic rotating sieve tray based on mechanical feeding equipment, which includes a cylindrical shell 1, fixed feet 101, a top cover 2, a feed port 201, a motor 3, a rotating shaft 4, a sieve tray 5, a vibration device 501, and a small size reduction Vibrator 502, fixing device 6 and movable plate 601; the top of the shell 1 is fixed with a top cover 2 by bolts, and one side of the top cover 2 is integrally provided with a feed port 201; the motor 3 is fixed by bolts On the side of the feed port 201; the top cover 2 is provided with a round hole in the middle, and the shaft of the motor 3 passes through the round hole, and a coupling is installed to splice and install the shaft 4; the middle of the bottom of the shell 1 is fixed by interference fit A bearing is provided, and one end of the rotating shaft 4 is fixedly arranged in the inner hole of the bearing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com