Multi-level filtering vibrating screen

A vibrating screen and stage filtration technology, applied in the field of machinery, can solve the problem of single screen mesh size and other problems, and achieve the effect of simple structure, reasonable design and extended screening function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

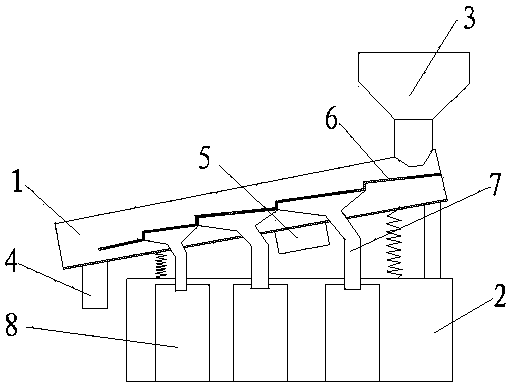

[0014] see figure 1 , a vibrating screen for multi-stage filtration, comprising a screen box 1, the screen box 1 is arranged on a bracket 2 inclined at a certain angle, the upper end of the screen box 1 is provided with a feed port 3, and the lower end is provided with a discharge port 4. The back of the screen box 1 is also provided with a vibrating motor 5. The screen 6 inside the screen box 1 has a multi-level stepped structure from the upper end to the lower end, and each step on the screen 6 The precision of the corresponding screens is different, and the material screening of different particle sizes can be completed in the screening process. The inclination angle of each step of the screen 6 can be the same or different, and the specific angle is selected according to the actual situation. Improve the time that the sieving on each step of the material stays, to improve the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com