Compounded double-mass vibratory screening equipment

A vibrating screening and double-mass technology, which is applied in solid separation, sieve, grille, etc., can solve the problems of structural damage of vibrating screen, clogging of screen, reduction of screening efficiency, etc. Easy to install and improve screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

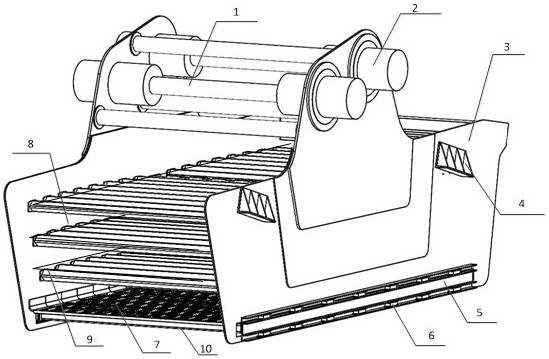

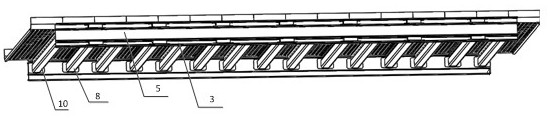

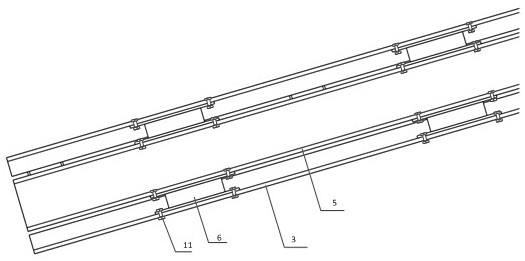

[0017] The technical scheme of the present invention is described in detail in conjunction with the accompanying drawings, a compound two-mass vibratory screening equipment, including a screen box, a vibrator 2 arranged on the screen box, and three vibrators arranged inside the screen box from top to bottom. One layer of rigid screening layer and one layer of elastic screening layer. In the rigid screening layer, the rigid screen 9 is installed on multiple groups of screen body beams 8 arranged in parallel, and the two ends of the screen body beam 8 are respectively connected to the oppositely arranged screens. The box side plate 3 is fixedly connected, and the elastic screen mesh 7 in the elastic screening layer is installed on multiple sets of parallel and alternately arranged floating frame beams 10 and screen body beams 8. The side plate 3 is fixedly connected, and the two ends of the floating frame beam 10 respectively pass through the opposite screen box side plate 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com