Automatic spanner and spanner fixture thereof

An automatic wrench and wrench technology, applied in the direction of wrenches, power tools, manufacturing tools, etc., can solve the problems of difficult operation and narrow adaptability, and achieve the effect of fast and convenient work, high work efficiency, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

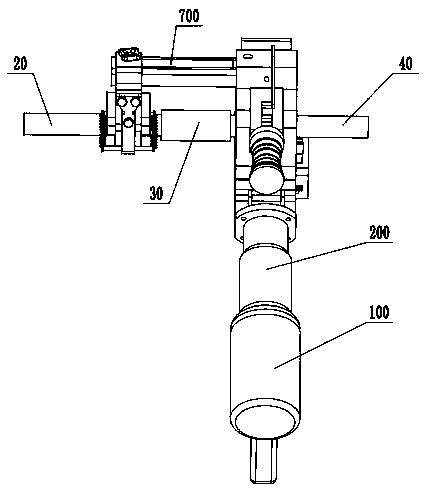

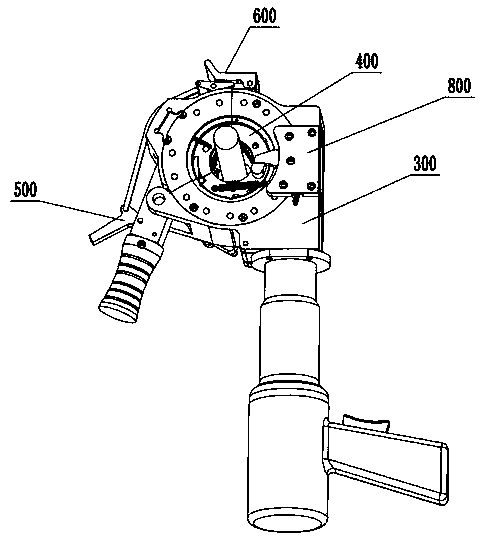

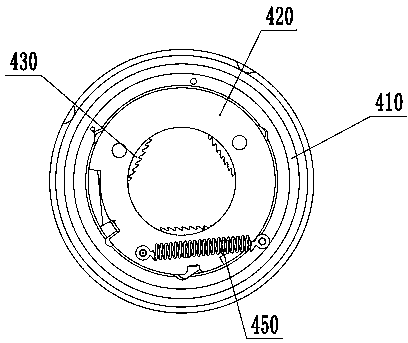

[0107] see Figure 3 to Figure 6 The first preferred embodiment of the shown wrench clamp of the present invention, the wrench clamp includes:

[0108] The outer ring 410 is a circular ring;

[0109] The inner ring 420 is a circular ring located inside the outer ring 410 and connected with the outer ring 410 by sliding or rolling;

[0110] Clamping jaws 430 are arranged in the inner ring 420, cooperate with the inner ring 420 and the outer ring 410 to clamp the workpiece; preferably, the clamping jaws 430 are wedge-shaped blocks, and the number of clamping jaws 430 is three and evenly distributed on the inner ring 420, the groove 4305 on each jaw 430 is slidingly matched with the support column 4201 on the inner ring 420; The supporting surface 4103 pushes the bearing surface 4301 on the jaws 430 to make the three jaws 430 move synchronously to the direction of clamping the workpiece to clamp the workpiece. The working surface where the jaws 430 contact with the workpiece is...

Embodiment 2

[0114] see Figure 7 to Figure 9 The second preferred embodiment of the shown wrench clamp of the present invention differs from the first preferred embodiment in that: the outer ring 410 and the inner ring 420 each include two parts; the main split support ring 421 is provided with The first stopper 440; the first stopper 440 cooperates with the positioning device 800 on the housing 300 to position the main cutting support ring 421 when it rotates in reverse;

[0115] The outer ring 410 includes:

[0116] main split worm gear 411; its sector angle is greater than or equal to 180°, and

[0117] Secondary splitting worm gear 412, whose fan angle is less than or equal to 180°; spliced with main splitting worm gear 411 to form a whole;

[0118] The inner ring 420 includes:

[0119] The main splitting support ring 421, whose fan-shaped included angle is greater than or equal to 180°, is the same as the fan-shaped included angle of the main splitting worm wheel 411, and is loc...

Embodiment 3

[0126] see Figure 10 to Figure 12 The third preferred embodiment of the wrench clamp of the present invention shown is different from the second preferred embodiment in that: the jaw 430 is a swing block, the outer ring 410 has a slot 4123, and the inner ring 420 contains Support column 4201, jaw 430 includes:

[0127] The extension part 4304 is located in the slot 4123;

[0128] The teeth 4306 are arranged on the working surface where the jaw 430 contacts the workpiece;

[0129] The hole 4303 is provided on the clamping jaw 430 and is rotatably connected with the support column 4201 .

[0130] The wrench fixture of this embodiment clamps the workpiece through the swing of the swing block, which has high flexibility and sensitive response. The wrench fixture of this embodiment can also adapt to a wide range of working diameters, and does not need to be replaced every time for workpieces of different specifications. Gripper, high work efficiency, fast and convenient work. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com