Leather storage rack capable of achieving automatic picking and storage

An automatic pick-and-place and storage rack technology, applied in the field of automatic pick-and-place leather storage racks, can solve the problems of inconvenient collection, easy rolling, and soiling the surface of raw materials, and achieve the effect of improving the placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

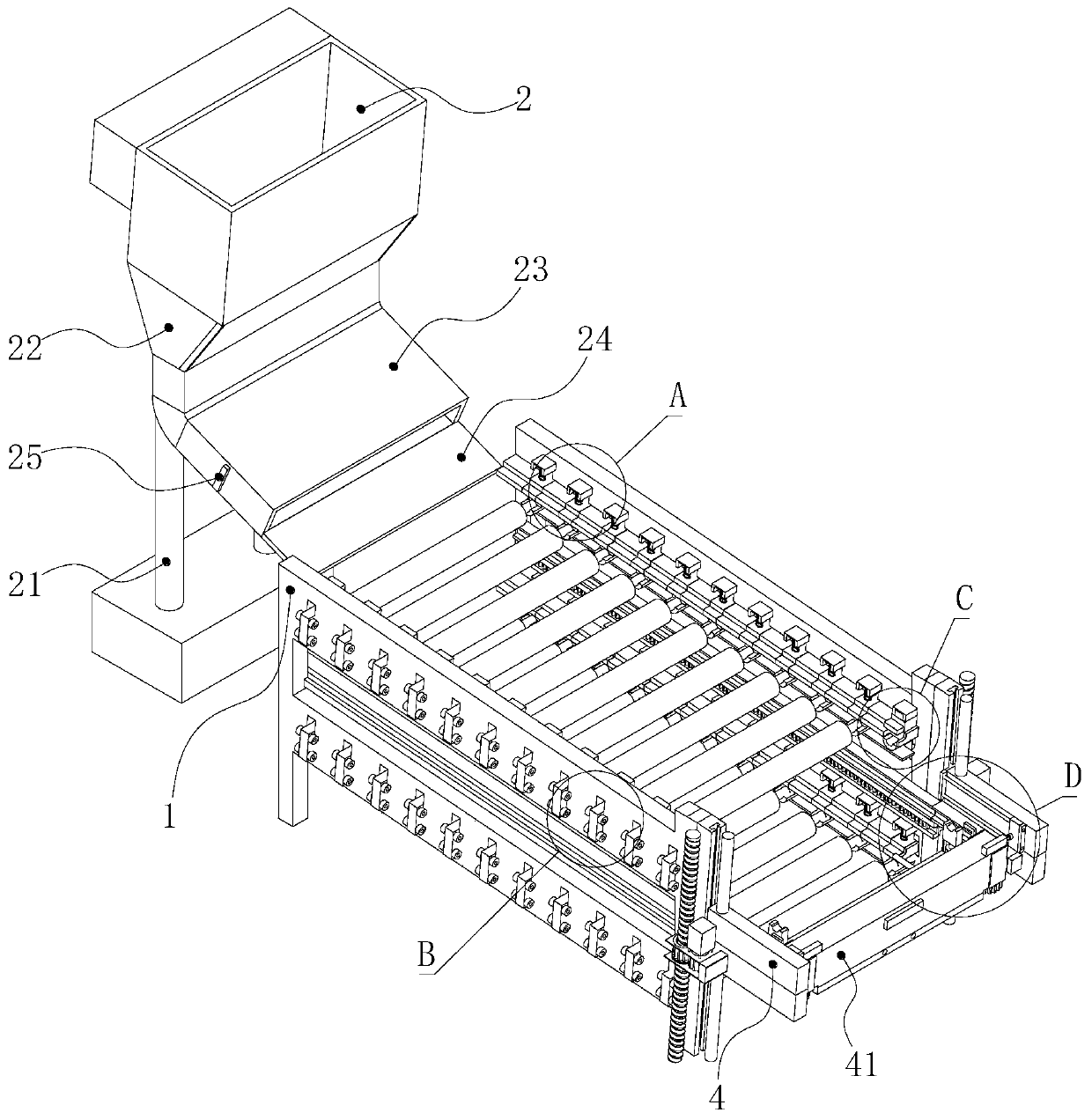

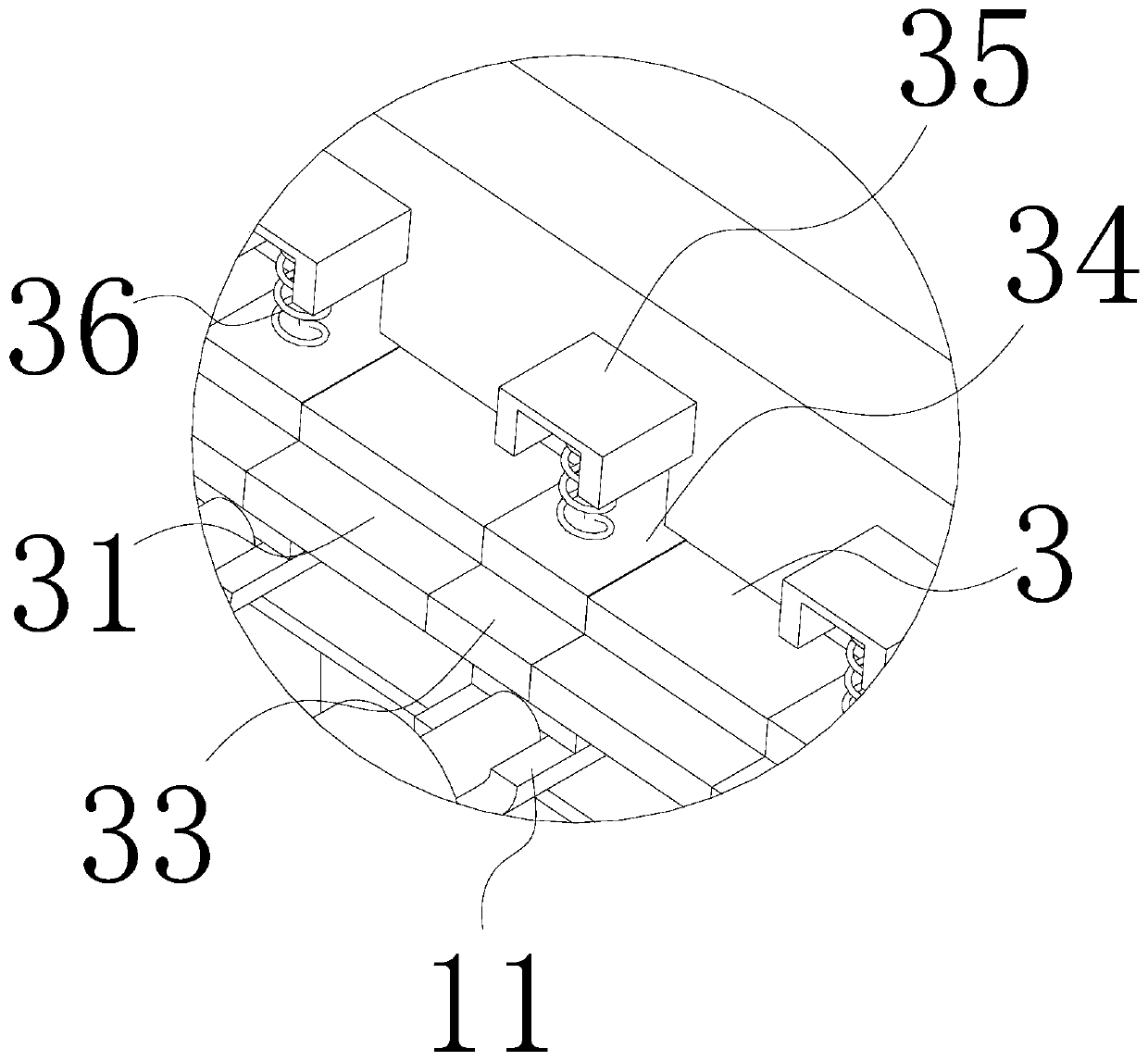

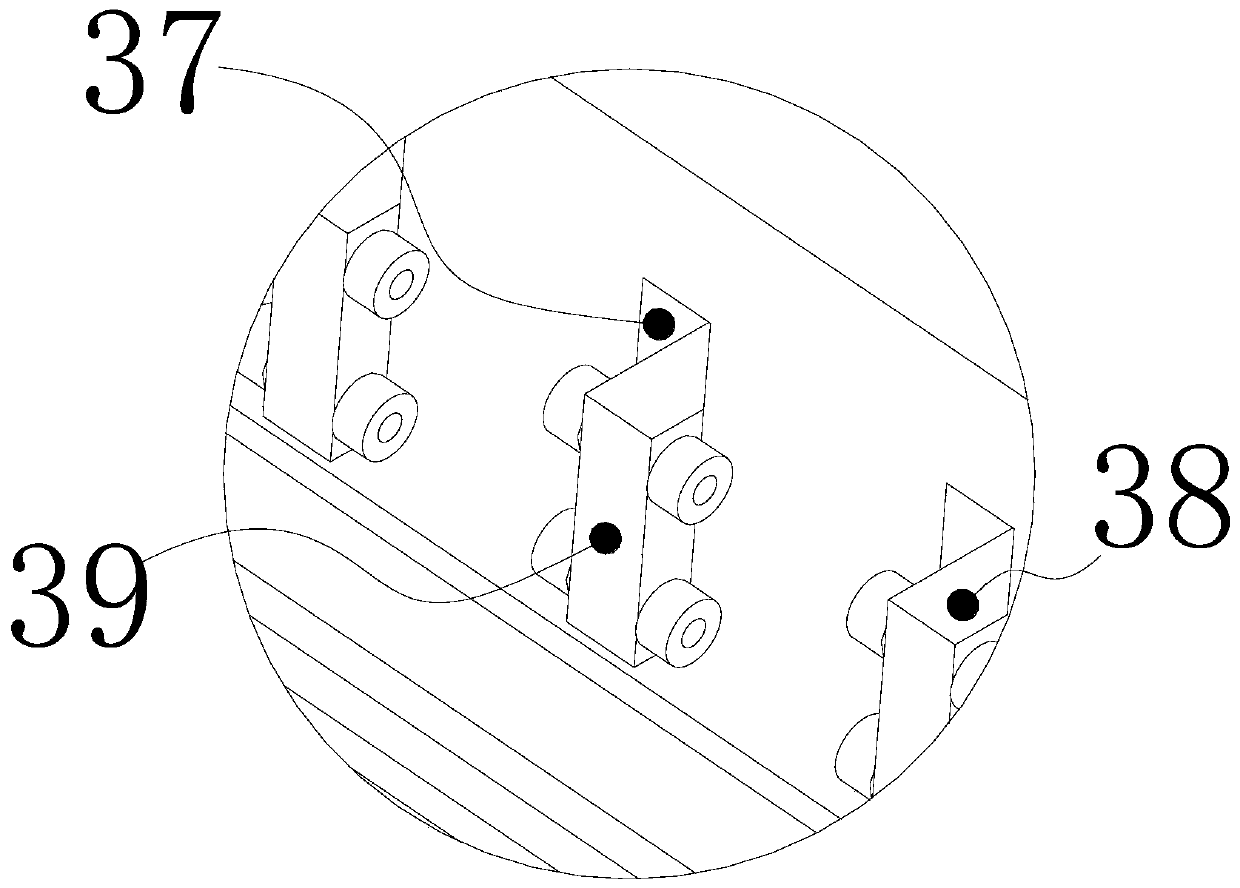

[0020] Such as Figure 1-7 As shown, an automatic pick-and-place leather storage rack, including a swing device, a fixing device, a loading device, and a pick-up device, the fixing device includes a fixing frame 1 and a card board 11, the fixing frame 1 is a conventional Metal frame, the clamping plate 11 is an arc-shaped bent plate, and the groove formed by the bending allows the end of the raw material roll to be clamped in, and is evenly and symmetrically arranged on both sides of the fixing frame 1, and sliding up and down relative to the fixing frame, as a preference , Multi-layer pallets can be set up to make more reasonable use of space, and each pallet is fixed with a number. The numbering method of the pallet can be marked in the form of coordinates, which is easy to find, and the raw material can be rolled by evenly setting the pallet Evenly distributed on the fixed frame, so that the raw material rolls do not touch each other, so as to prevent the raw material rolls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com