An Intelligent Coal Shearer Cutting Pattern Recognition System

A pattern recognition and shearer technology, applied in character and pattern recognition, slitting machinery, earthwork drilling and mining, etc., can solve problems such as insufficient recognition accuracy and complex detection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below according to the accompanying drawings.

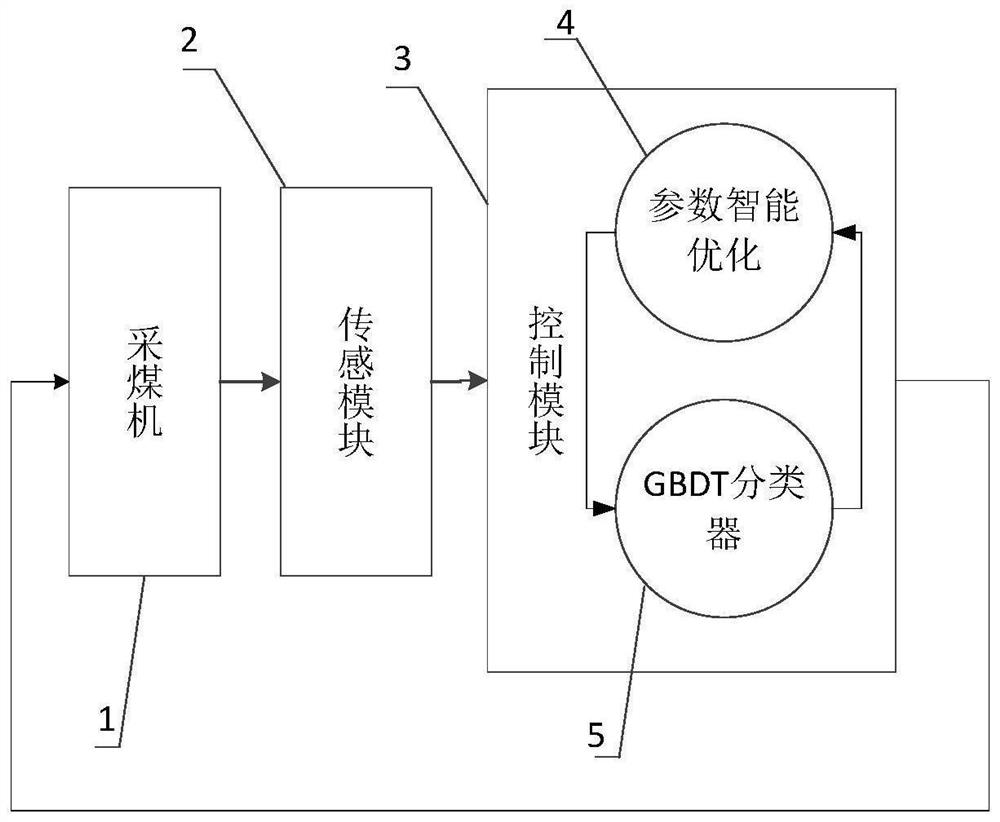

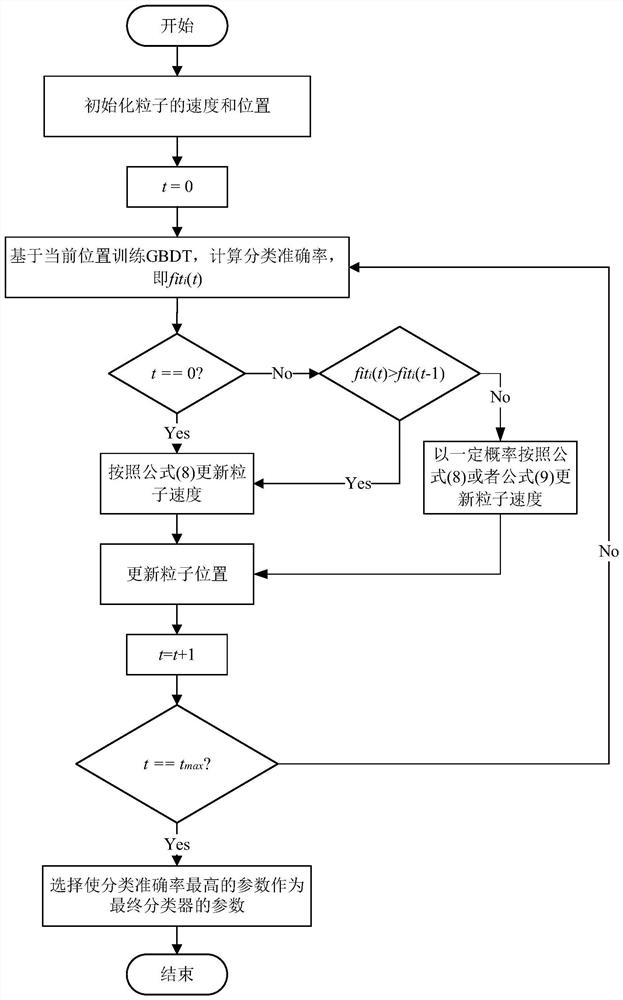

[0035] refer to figure 1, an intelligent shearer cutting pattern recognition system, the system is composed of a sensing module 2 and a control module 3, wherein the control module 3 is composed of a parameter intelligent optimization part 4 and a GBDT classifier 5. The connection mode of each module is: the sensor module 2 measures the running speed, current and voltage of the motor of the shearer 1 when it is working, and transmits these data to the control module 3; the control module intelligently identifies the current geological conditions according to the operating data , and transmit the result to the shearer 1 so that the shearer can adjust the cutting mode in time. The control module includes a coal-rock interface recognition model. The model uses the gradient boosting tree GBDT as a classifier, and uses an optimization algorithm to optimize the two parameters n_...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com