A Reliable Cutting Pattern Recognition System of Coal Shearer

A pattern recognition and shearer technology, applied in testing machinery, mining equipment, earth-moving drilling, etc., can solve the problems of complex detection equipment and inability to accurately extract signal features, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below according to the accompanying drawings.

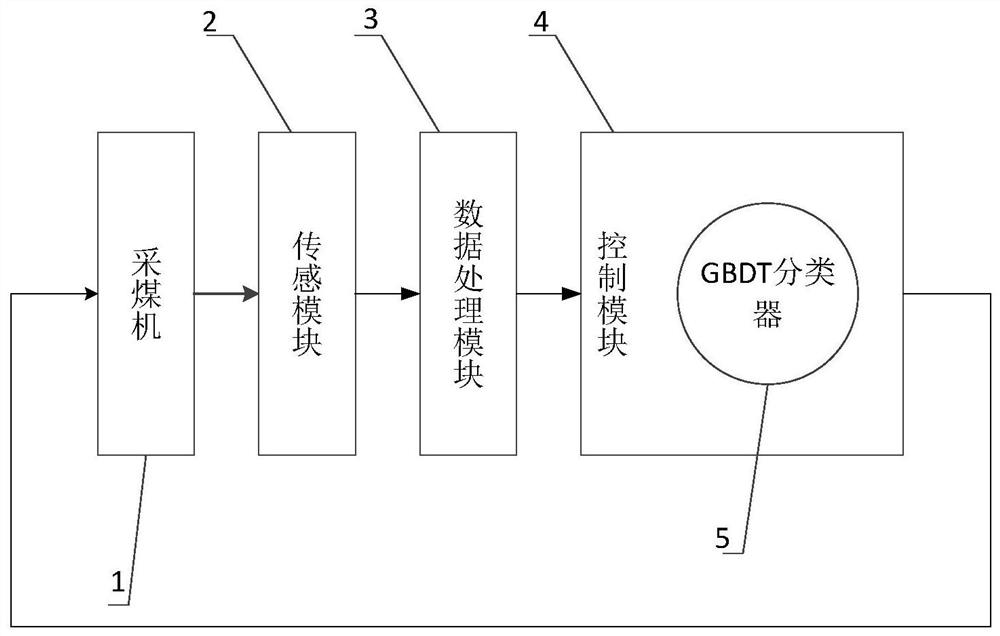

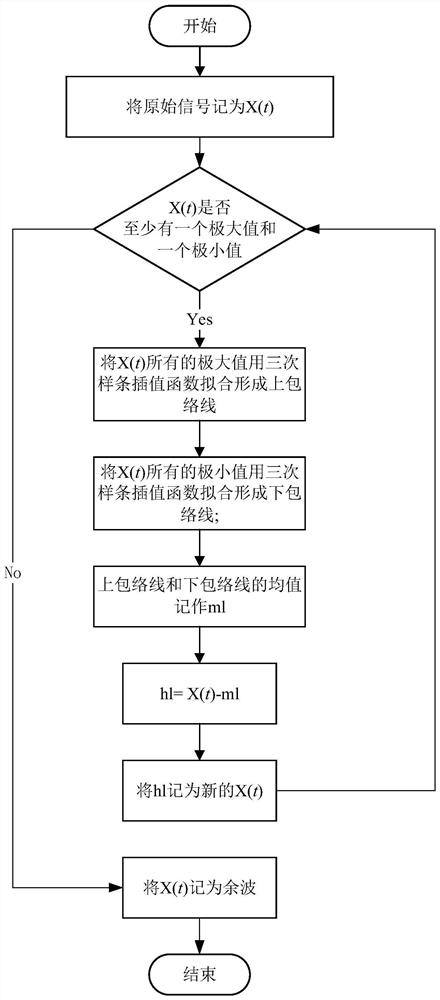

[0025] refer to figure 1 , a reliable shearer cutting pattern recognition system, the system is composed of sensing module 2, data processing module 3, and control module 4. The connection mode of each module is: the sensing module 2 measures the operating speed, current and voltage of the motor when the shearer 1 is working, and transmits these data to the data processing module 3; the data processing module 3 controls the speed, current and voltage three Each signal is decomposed separately, and all the decomposed signals are transmitted to the control module 4; the control module 4 intelligently recognizes the current geological conditions according to the input data, and transmits the result to the shearer 1 so that the shearer 1 can adjust the cutting mode in time. Wherein, the data processing module 3 decomposes the three signals of speed, current and voltage respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com