Needle plate needle pulling device

A needle plate, a pair of technology, applied in the deburring device, textile and paper making, fiber processing, etc., can solve the problems of damage, needle deformation, time-consuming, labor-intensive and dangerous, etc., to achieve reliable operation, avoid bending deformation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

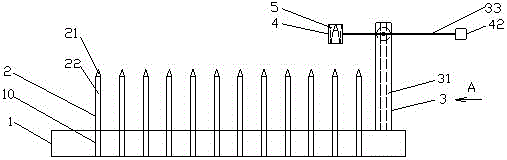

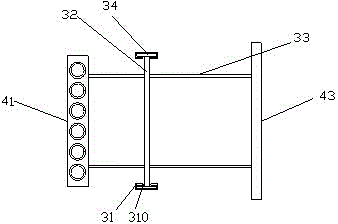

[0021] The present invention as Figure 1-5 As shown, the needle plate 1 is included, and the needle plate 1 is uniformly provided with perforations 10 for connecting the needles 2, and the needle has a needle point 21 and a needle body 22; it also includes a guide mechanism 3 and an auxiliary mechanism 4, and the guide mechanism Located at one end of the top surface of the needle plate, the guide mechanism includes a pair of parallel slide rails 31, a slide bar 32 and a pair of parallel straight bars 33,

[0022] Described slide rail 31 is vertically arranged on the needle plate, and described slide rail is a rectangular frame, and the inboard of described slide rail is provided with slideway 310, and the slideways of a pair of slide rails 31 are arranged relatively, and the two sides of described slide bar 32 Sliders 34 are respectively provided at the ends, the sliders are located in the slide rail, and the slide bar is located in the slide track, so that the slide bar is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com