Paste mixing and coated plate system of storage battery

A battery and plate coating technology, which is applied in the field of battery and paste coating system, can solve the problems of complex material transportation, discontinuous battery production, etc., and achieve the effect of compact system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

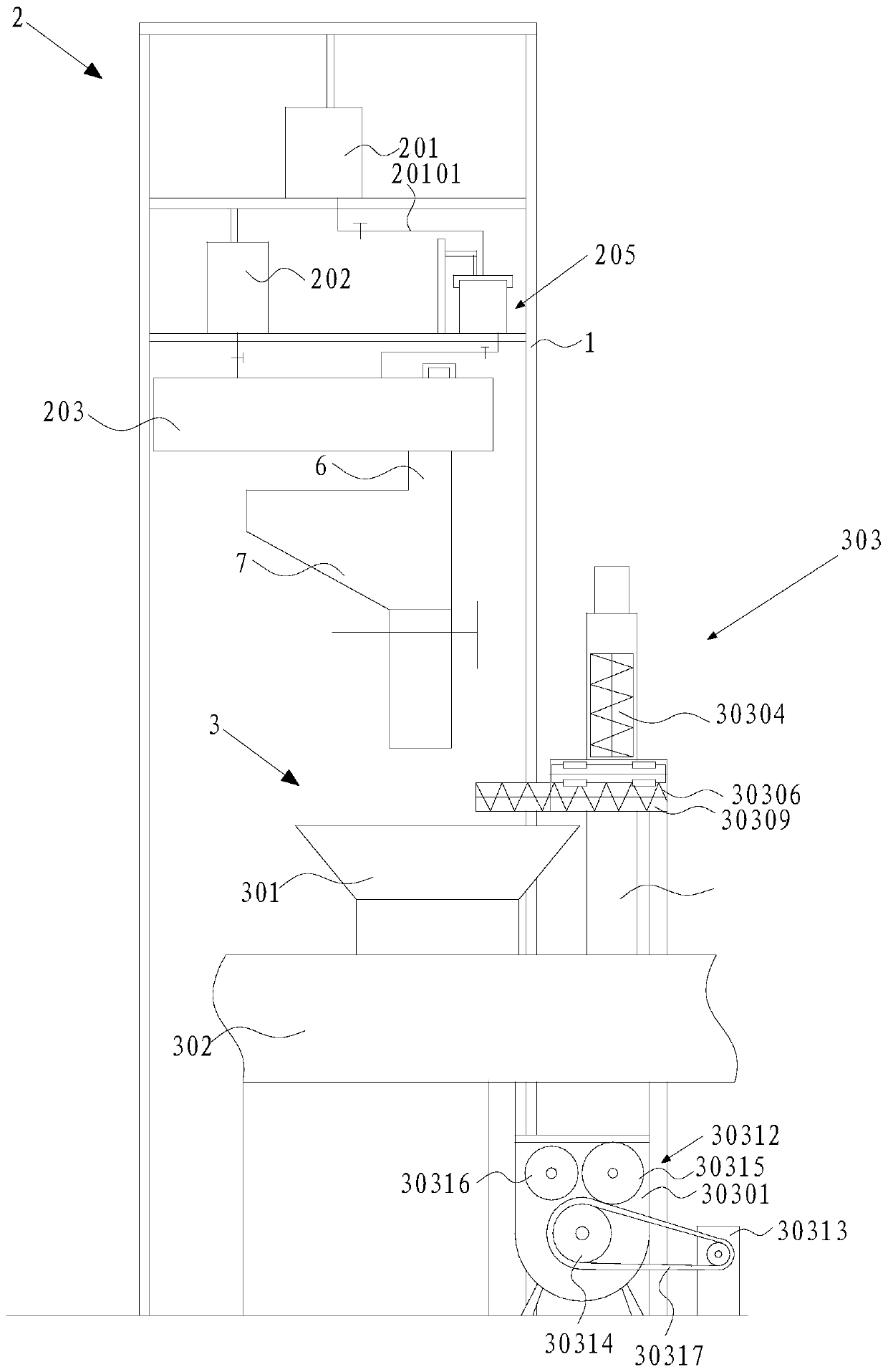

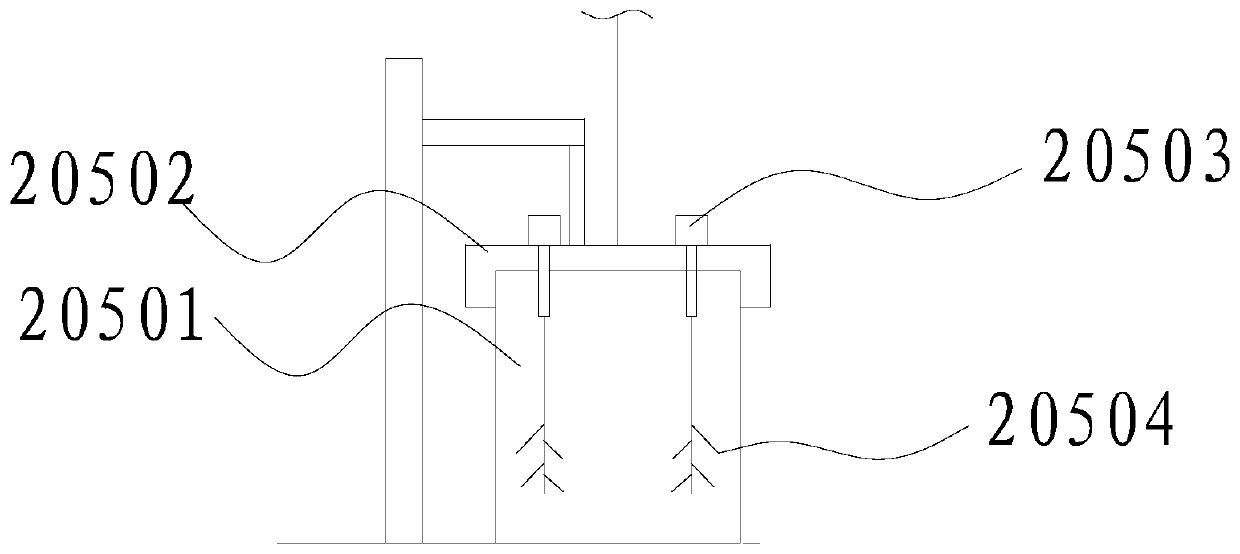

[0055] Such as Figure 1~5 As shown, the battery and paste coating system of this embodiment includes a frame 1 , a paste module 2 and a coating module 3 . The paste mixing module 2 includes an acid solution tank 201 , a water tank 202 , a mixing chamber 203 and a side opening switch door 204 for the mixing chamber. The coating module 3 includes a lead paste hopper 301 and a coating unit 302 .

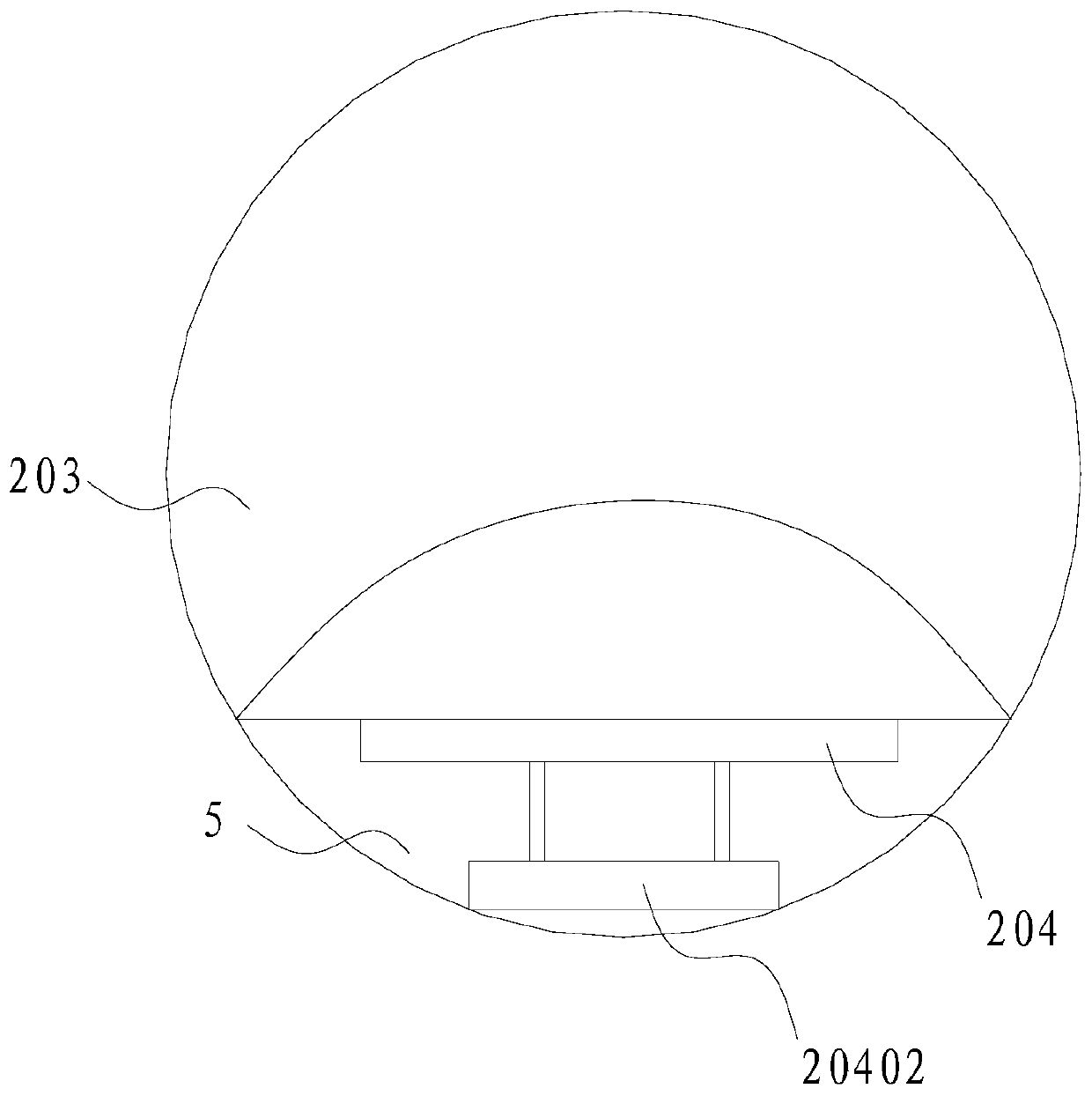

[0056] The mixing chamber 203 is connected to the discharge chamber 5. A mixing chamber switch door 204 is installed in the discharge chamber 5. The bottom of the discharge chamber 5 is connected with a discharge pipe 6. The bottom of the discharge pipe 6 is arranged and connected to the storage bin 7 and the lead paste hopper. 301 is arranged directly below the bottom outlet of the storage bin 7 .

[0057] The opening and closing door 204 of the mixing chamber includes: an opening and closing door matched with the side opening of the mixing chamber 203 and a push-pull cylinder 20402...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com