Rotary buckle structure, antenna plate and assembly method thereof

A technology of rotating buckle and assembling method, applied in the direction of antenna support/installation device, etc., can solve the problems of increasing the difficulty of parts classification, increasing the weight and manufacturing cost of the antenna, and reducing the versatility of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

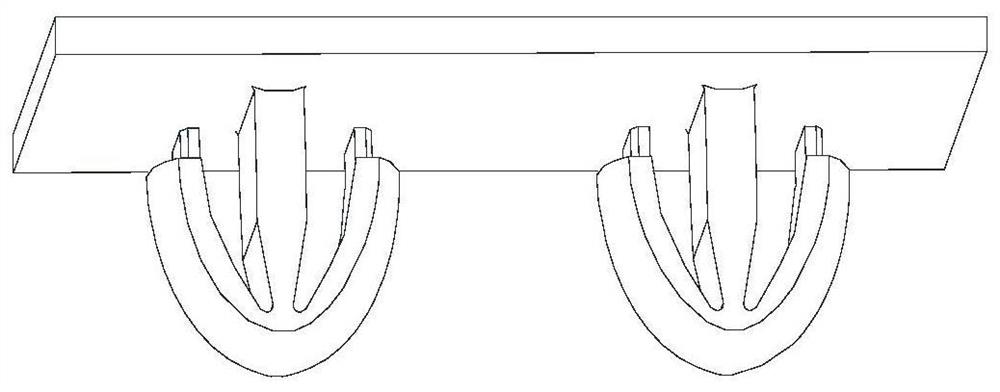

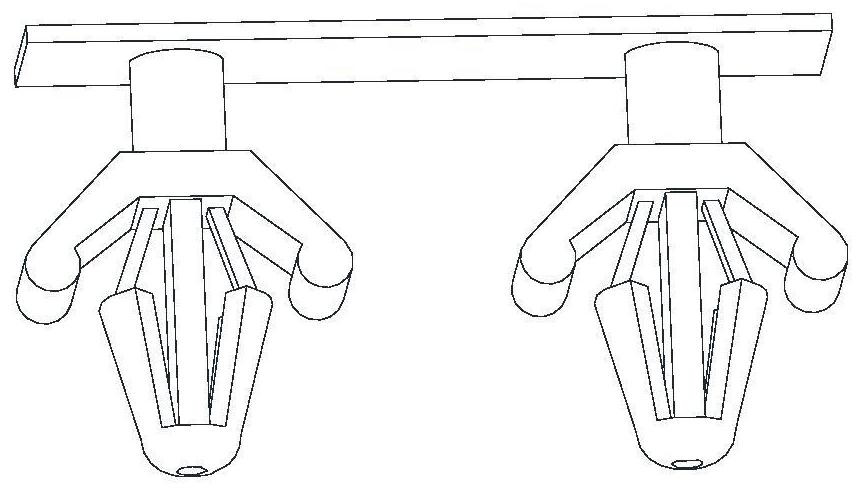

[0031] Figure 4 A preferred embodiment of the rotary buckle structure of the present invention is shown, as Figure 4 and Figure 5 As shown, the rotating buckle structure includes: a top plate 1, a shaft 11, a clamping part 12 and two elastic supporting surfaces 13; the clamping part 12 is arranged on the first end of the shaft 11, and the second end of the shaft 11 Arranged on the top plate; two support surfaces 13 are symmetrically arranged on both sides of the shaft 11 with respect to the axis of the shaft 11, and one end of each support surface 13 is connected to one side of the top plate, and the other end of each support surface is provided with a fixing part ; The fixed part faces the direction where the clamping part 12 is located.

[0032] Specifically, for example, the cross-sectional shape of the shaft 11 may be a circle, an ellipse, a polygon, or the like. And, the clamping part 12 is disposed on the first end of the shaft 11 , for example, the clamping part 1...

Embodiment 2

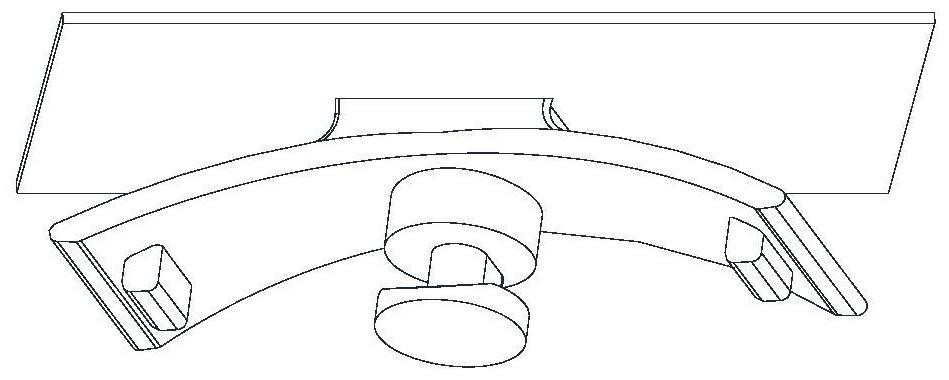

[0051] Such as Figure 6B As shown, the present invention also provides an antenna panel 2, including: clamping holes 21 and at least one pair of fixing holes provided on the antenna panel 2; the fixing holes are symmetrically arranged around the clamping holes 21; and clamping The hole 21 is opposite to the clamping part 12; there is a certain offset between the fixing hole and the fixing part.

[0052]Specifically, in this embodiment, a pair of fixing holes are provided on the antenna plate 2 as an example for illustration, but this is not intended to limit the protection scope of the present invention. And, a clamping hole 21 is opened on the antenna plate 2 , and the clamping hole 21 is opposite to the clamping part 12 , that is, the clamping hole 21 is used to cooperate with the clamping part 12 . And make the fixing hole position symmetrically arranged around the clamping hole position 21, that is, the arrangement of the fixing hole position and the fixing part is consi...

Embodiment 3

[0057] The present invention also provides a method for assembling the above-mentioned rotating buckle structure and the above-mentioned antenna panel 2, including: placing the clamping part 12 against the clamping hole 21, so that the clamping part 12 is inserted into the clamping hole 21; 11 is rotated at a certain angle, so that the fixing falls into the fixing hole, and the clamping part 12 and the clamping hole 21 are dislocated.

[0058] Specifically, the clamping part 12 of the rotating buckle structure is opposed to the clamping hole 21 of the antenna panel 2, and the clamping part 12 is inserted into the clamping hole 21; after that, the shaft 11 of the rotating buckle structure Rotate at a certain angle, and then drive the supporting surface 13 and the clamping part 12 to rotate at a certain angle, so that the fixing on the supporting surface 13 falls into the fixed hole position, and make the clamping part 12 and the clamping hole 21 misaligned to complete the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com