Steel plate drilling device

A drill and steel plate technology, applied in the direction of boring/drilling, drilling/drilling equipment, large fixed members, etc., can solve the problems of increasing the difficulty of adjusting the position, affecting work efficiency, etc., to increase safety, Increased convenience and beneficial control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Preferred embodiments of the invention are described below in conjunction with the accompanying drawings:

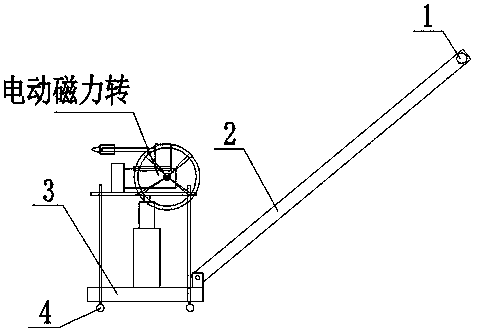

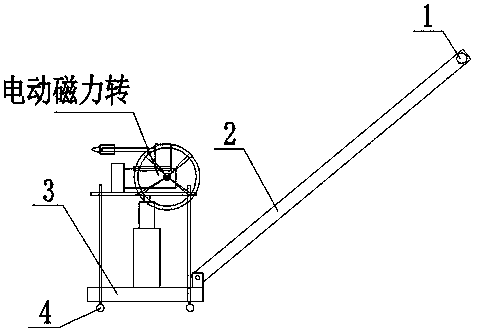

[0010] Such as figure 1 As shown, a steel plate drill includes a hand push rod 1, a connecting rod 2 connected to the hand push rod 1, a base 3 connected to one end of the connecting rod 2 carrying a hydraulic jack, and four A supporting wheel 4 with a locking device, a positioning bracket is arranged on the supporting wheel 4, a bearing tray that can slide up and down relative to the positioning bracket is arranged on the top of the base 3 and on the positioning bracket, and the bottom of the supporting tray is movably connected with a hydraulic jack. An electric magnetic drill is fixed laterally on the upper part of the loading tray.

[0011] The principle of the present invention: the present invention can slide the base on the positioning bracket through the hydraulic jack, and adjust the height position of the electric magnetic drill; the body body can be ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com