Longitudinal butt joint auxiliary support device

An auxiliary support and longitudinal technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of increased weight of parts, time-consuming and labor-intensive, potential safety hazards, etc., and achieve the effects of improving assembly safety, convenient use, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing water preferred embodiment of the present invention is described:

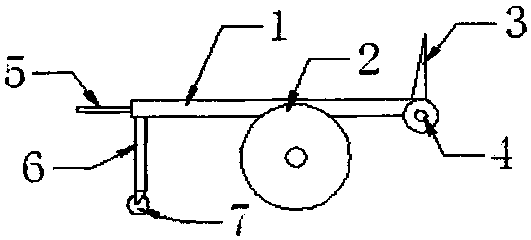

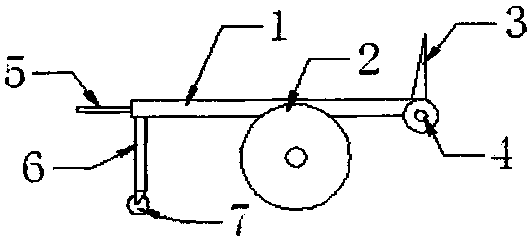

[0010] Such as figure 1 As shown, the invention is a longitudinal docking auxiliary support device, the main moving wheel 2 is installed on the lower side of the middle part of the support plate 1, the booster plate 3 is installed on the upper side of the right end of the support plate 1, and the torsion spring is installed on the lower side of the booster plate 3 Connecting shaft 4, support plate 1 left lower end is equipped with bracket 6, and support plate 6 lower end is equipped with auxiliary mobile wheel 7, and support plate 1 left end is equipped with telescopic extension frame. Described support plate 1 is provided with pressure sensor, and described booster plate An alarm 5 is arranged on it.

[0011] When in use, use the support plate 1 to support the parts, and adjust the position of the movement through the main moving wheel 2 and the auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com