Bottom unloading type material conveying device with working condition sound pickup device

A sound pickup device and working condition sound technology, which is applied in the direction of transportation of passenger cars, underground transportation, transportation and packaging, etc., can solve the problems of not being able to monitor normal operation, etc., and achieve the effect of reducing labor intensity and facilitating unloading of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

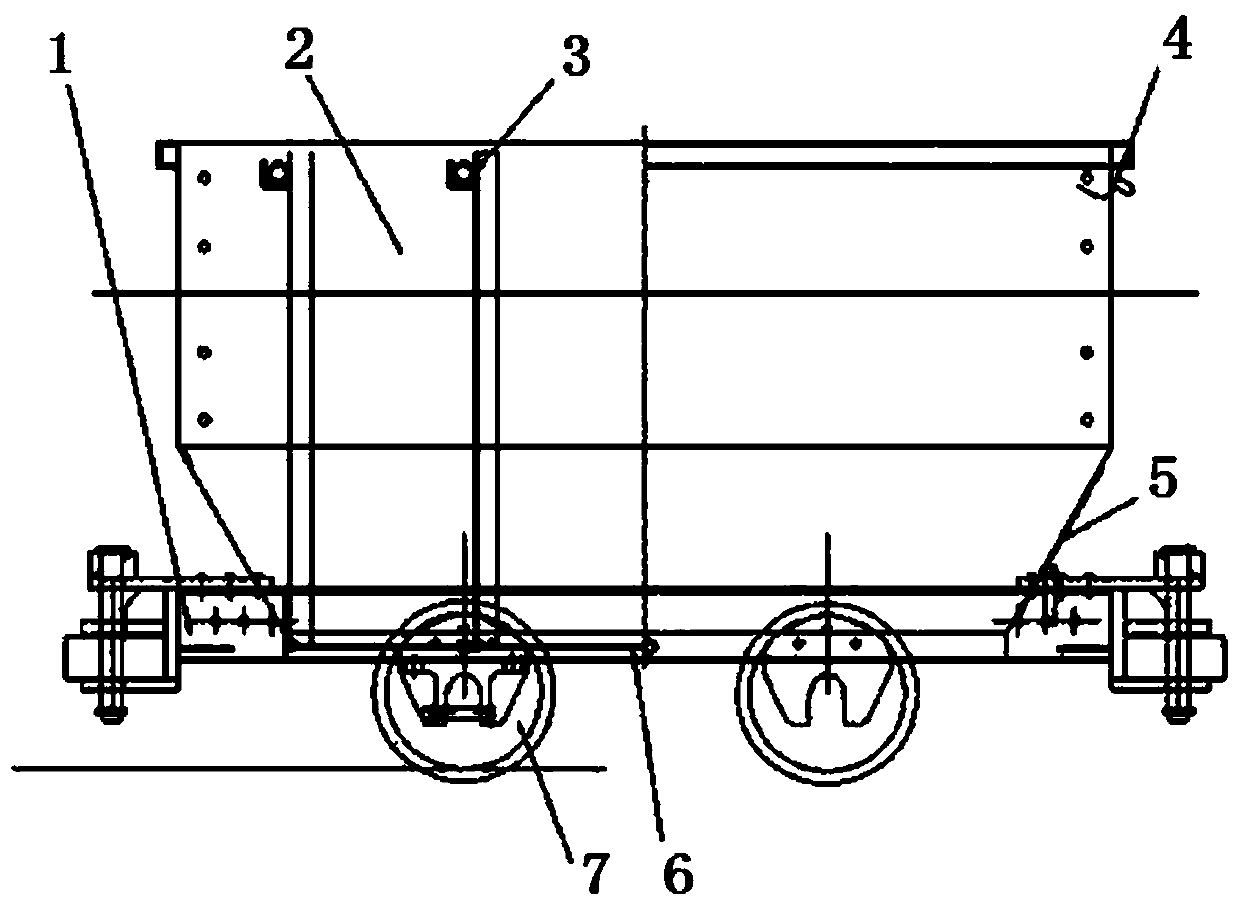

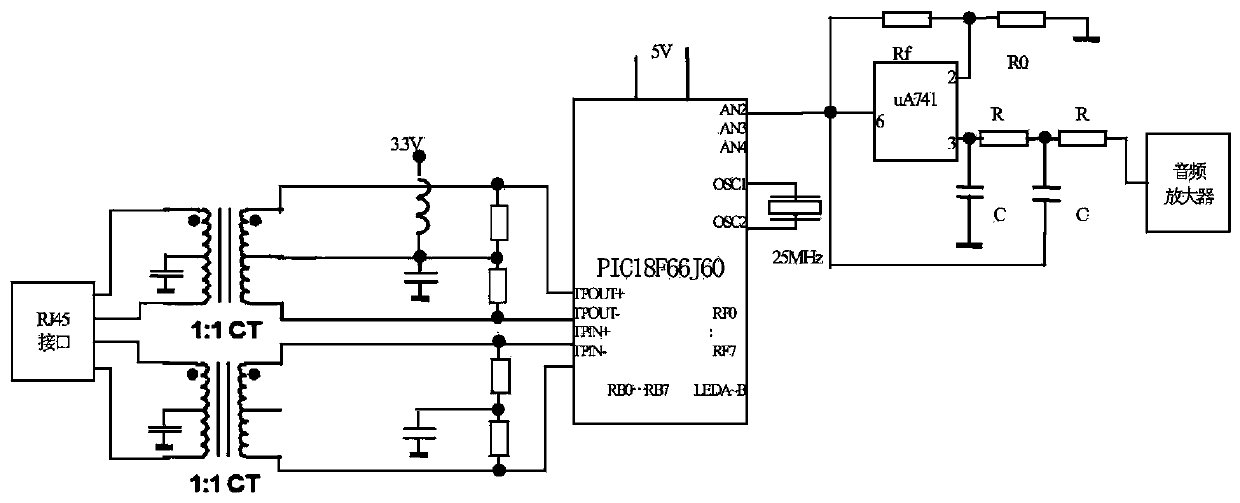

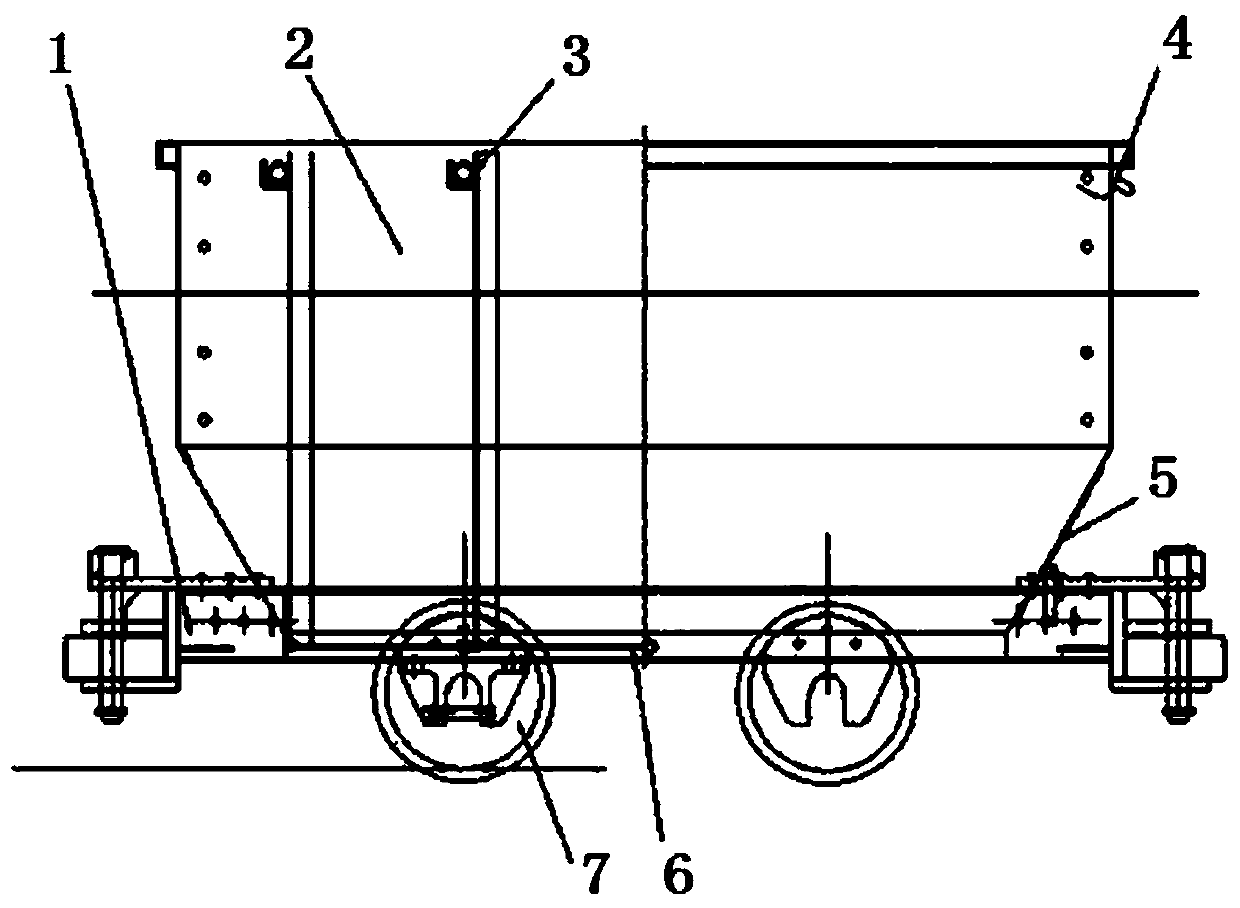

[0018] The specific structure of the present invention will be described in detail according to the accompanying drawings. The bottom unloading material conveying device with working condition sound pickup device comprises a vehicle frame 1 and a working condition sound pickup device, a compartment 2 is arranged on the vehicle frame 1, and wheels are arranged below the vehicle frame 1, and it is characterized in that the compartment 2 The inner cavity is equipped with a bottom-loading reverse sliding door, which includes a hinged partition and baffle 6, which are distributed at 90 degrees, and there is a handle 3 on the top of the partition. There is an installation shaft on the plate 6, and the two sides of the installation shaft are installed on the bottom of the compartment 2; the bottom unloading reverse sliding door includes a hinged partition plate and a baffle plate 6, and the partition plate and the baffle plate 6 are distributed at 90 degrees, and the partition plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com