Food processing device

A food processing and equipment technology, which is applied in the field of food processing equipment, can solve the problems of purchasing funds restricting the development of small and medium-sized businesses, and achieve the effects of simple structure, enhanced crushing effect, and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

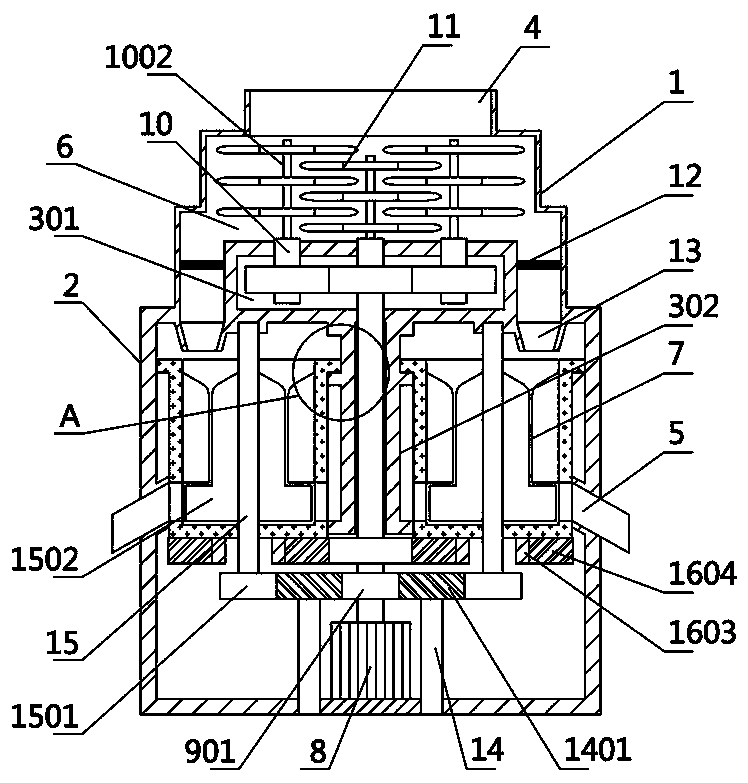

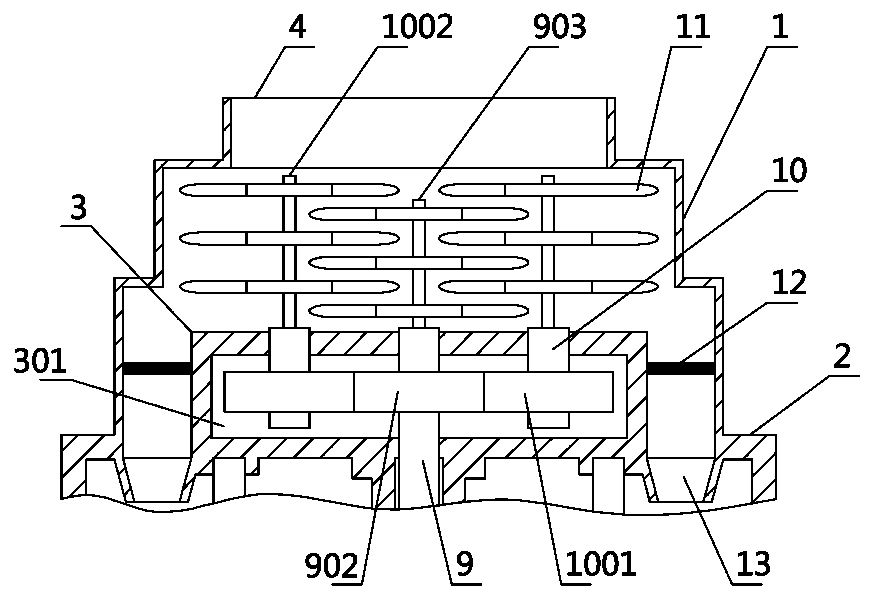

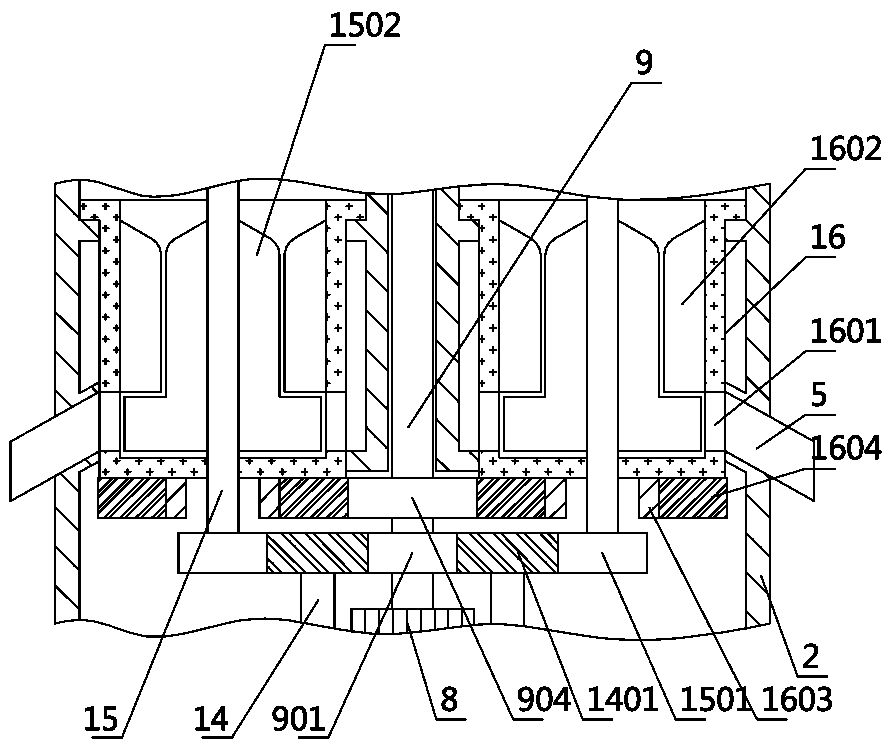

[0020] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a food processing equipment, including a housing 3, a crushing mechanism 6, a grinding mechanism 7 and a motor 8, the housing 3 includes a cavity 301 and a sealing cylinder 302, the cavity The crushing mechanism 6 is provided on the upper side of the 301, and the crushing mechanism 6 includes two first auxiliary shafts 10 and a crushing turntable 11 located on the left and right sides of the main shaft 9, and the upper side of the first auxiliary shaft 10 is rotationally connected with the upper side of the cavity 301, and the first The side of the auxiliary shaft 10 located in the cavity 301 is fixedly connected to the fourth gear 1001, the fourth gear 1001 is meshed with the second gear 902 on the side of the main shaft 9, and the upper end of the main shaft 9 is respectively connected to the upper and lower sides of the cavity 301 in rotation, and the main shaft 9 The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com