A method and application of preparing heavy metal chromium adsorbent by dredging sediment of Dianchi Lake

A technology for dredging sediment and heavy metals, applied in the directions of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., to achieve the effects of high product yield, increased adsorption capacity, and simple operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

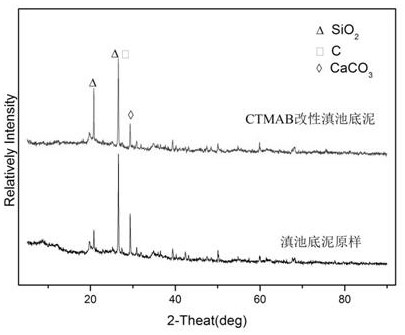

Method used

Image

Examples

Embodiment 1

[0020] Example 1: A method of preparing a metal chromium adsorbent using Dianchi dredged slot, the specific steps are as follows:

[0021] (1) Wash the dredging of the dodge dredging in the removal impurity to wash to neutral, solid-liquid separation, solids at a temperature of 60 ° C under conditions, temperature treatment 24 h and ground to a particle size of 160 to 180 mesh, resulting in pretreatment Dredging of the slurry;

[0022] (2) Salvation of hexadalkyltrimel bromide was prepared into an organic modified solution in deionized water; therein in the organic modified solution of hexamethyltrimethylammonium concentration was 0.01 g / mL;

[0023] (3) The pretreatment dredging of step (1) is added to the organic modified solution of step (2) for 2.0 h, and the pressure is filtered under reduced pressure to obtain a solid, washed with distilled water to neutral, and the solid is placed at a temperature of 60. The constant temperature treatment under ° C was treated with 12 h a...

Embodiment 2

[0026] Example 2: A method of preparing a metallic chromic adsorbent using Dianchi Dredging Terminal, the specific steps are as follows:

[0027] (1) Wash the dredging of the diolite dredging joint to remove impurities to the neutralized water, solid-liquid separation, the solid is placed under temperature of 80 ° C for 18 h and ground to the particle size of 180 to 190 to obtain pre-treatment dredging Undermoth;

[0028] (2) Salvation of hexadalkyltrimethylammonium bromide was formed into an organic modified solution in deionized water; wherein the concentration of adjacent ammonium trimethyl bromide in an organic modified solution was 0.02 g / ml;

[0029] (3) The pretreatment dredging of step (1) is added to the organic modified solution of step (2) to treat 0.5 h, and the decompression is filtered to obtain a solid, washed to neutral with distilled water, and the solid is placed at a temperature of 75. The constant temperature treatment under ° C for 18 h and ground 180 mesh s...

Embodiment 3

[0031] Example 3: A method of preparing a metal chromium adsorbent using Dianchi Dredged Terminal, the specific steps are as follows:

[0032] (1) Wash the dredging of the dioli dredging in the removal impurity to wash to neutral, solid-liquid separation, the solid is placed at a temperature of 90 ° C under conditions, and the particle size is 190 ~ 200 to obtain pretreatment dredging Undermoth;

[0033] (2) Salvation of hexadalkyltrimethylammonium bromide was prepared into an organic modified solution in deionized water; wherein the concentration of adjacent ammonium trimethyl bromide in an organic modified solution was 0.03 g / mL;

[0034] (3) The pretreatment dredging of step (1) is added to the organic modified solution of step (2) for 1.0 h, and the pressure is filtered under reduced pressure to obtain a solid, and the solid is washed to neutral, the solid is placed at a temperature of 90. The constant temperature treatment is 24 h under ° C and ground 200 mesh sieve to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com