Die-casting mould steel ingot whole-process full-sealing gas protection casting device

A gas-protected, fully-sealed technology, applied in the field of metallurgy, can solve problems such as large nitrogen absorption, various oxide inclusions, and low automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

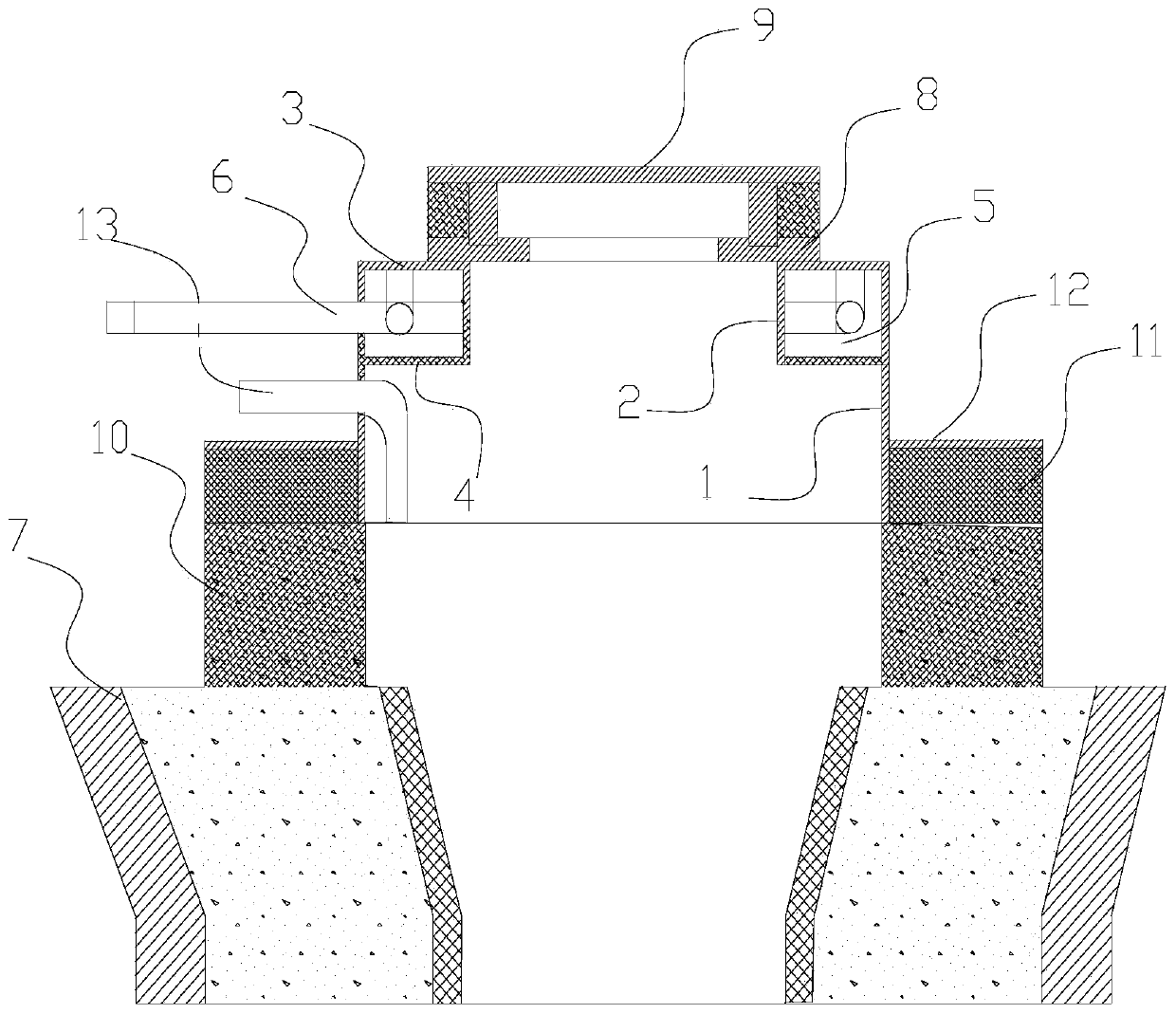

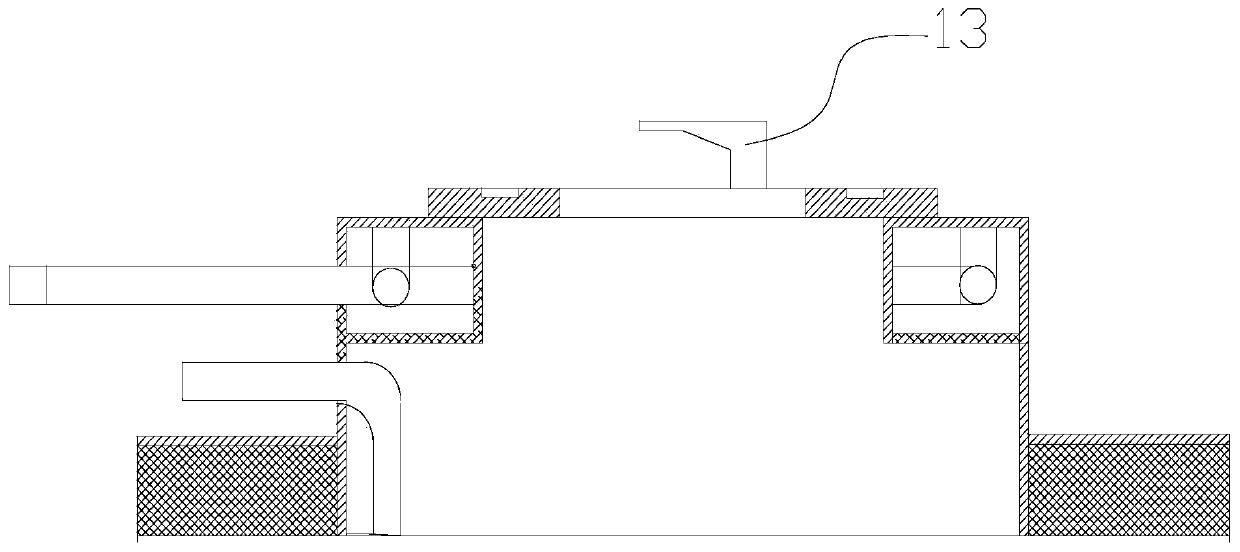

[0022] like figure 1 As shown, in the embodiment of the present invention, a casting mold steel ingot is provided with a full-sealed gas protection pouring device throughout the whole process. The device is installed between the bottom of the ladle and the middle column pipe 7 for pouring. The pouring device includes The outer cylinder body 1 and the inner cylinder body 2 arranged coaxially with the injector tube are respectively provided with an annular top plate 3 and a porous bottom plate 4 between the outer cylinder body 1 and the inner cylinder body 2, the outer cylinder body 1, the inner cylinder body 2 The cylinder body 2, the top plate 3 and the porous bottom plate 4 form an annular cavity 5, and an argon gas ring 6 is arranged in the annular cavity 5, and one end of the argon gas ring 6 protrudes from the annular cavity 5 and is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap