Full-automatic annular stereoscopic warehousing device with sorting function

A fully automatic, three-dimensional warehouse technology, applied to storage devices, transportation and packaging, conveyor objects, etc., can solve the problems of inability to realize automation, inconvenient disassembly and assembly, and large space occupation, so as to reduce labor intensity and space usage of workers The effect of high efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

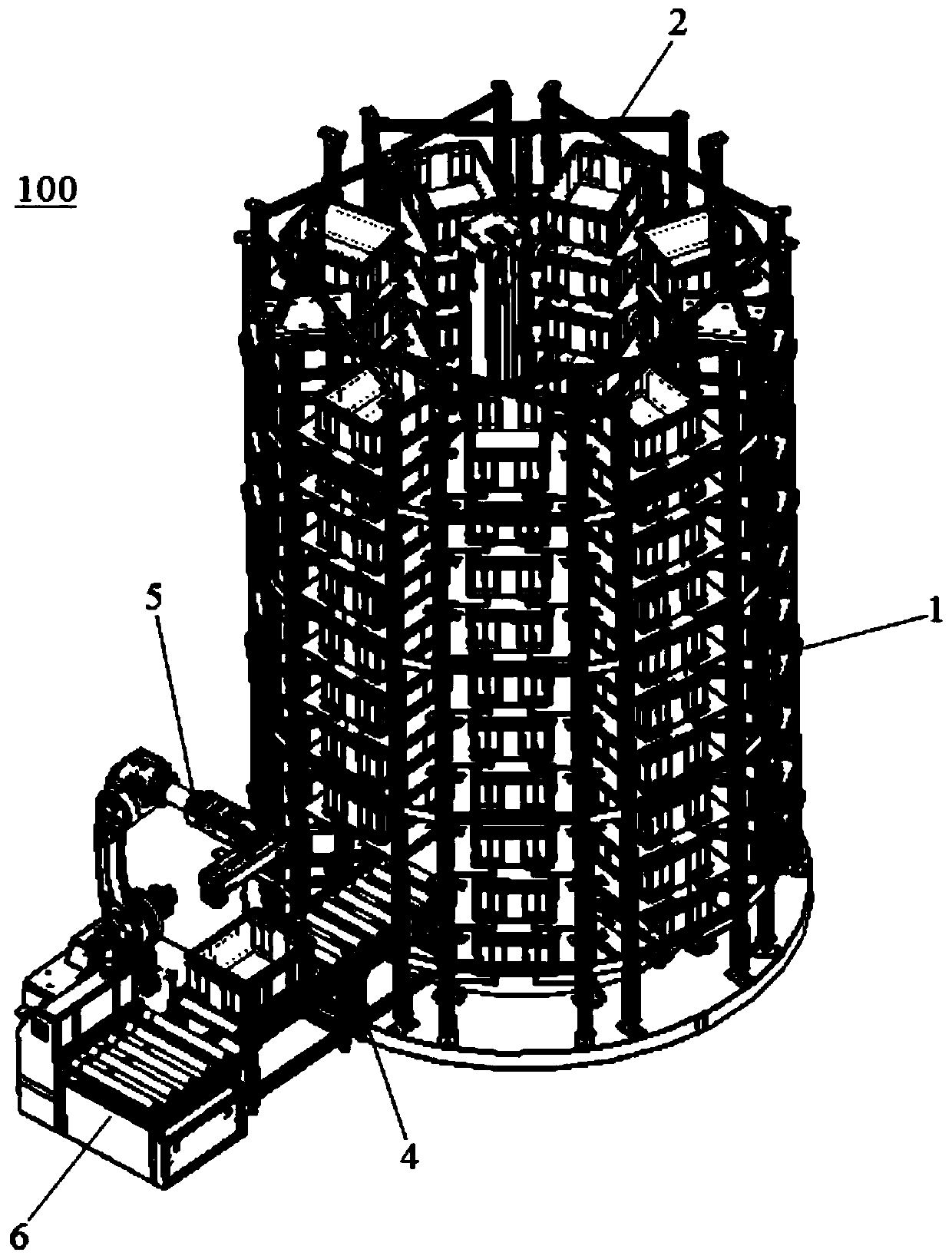

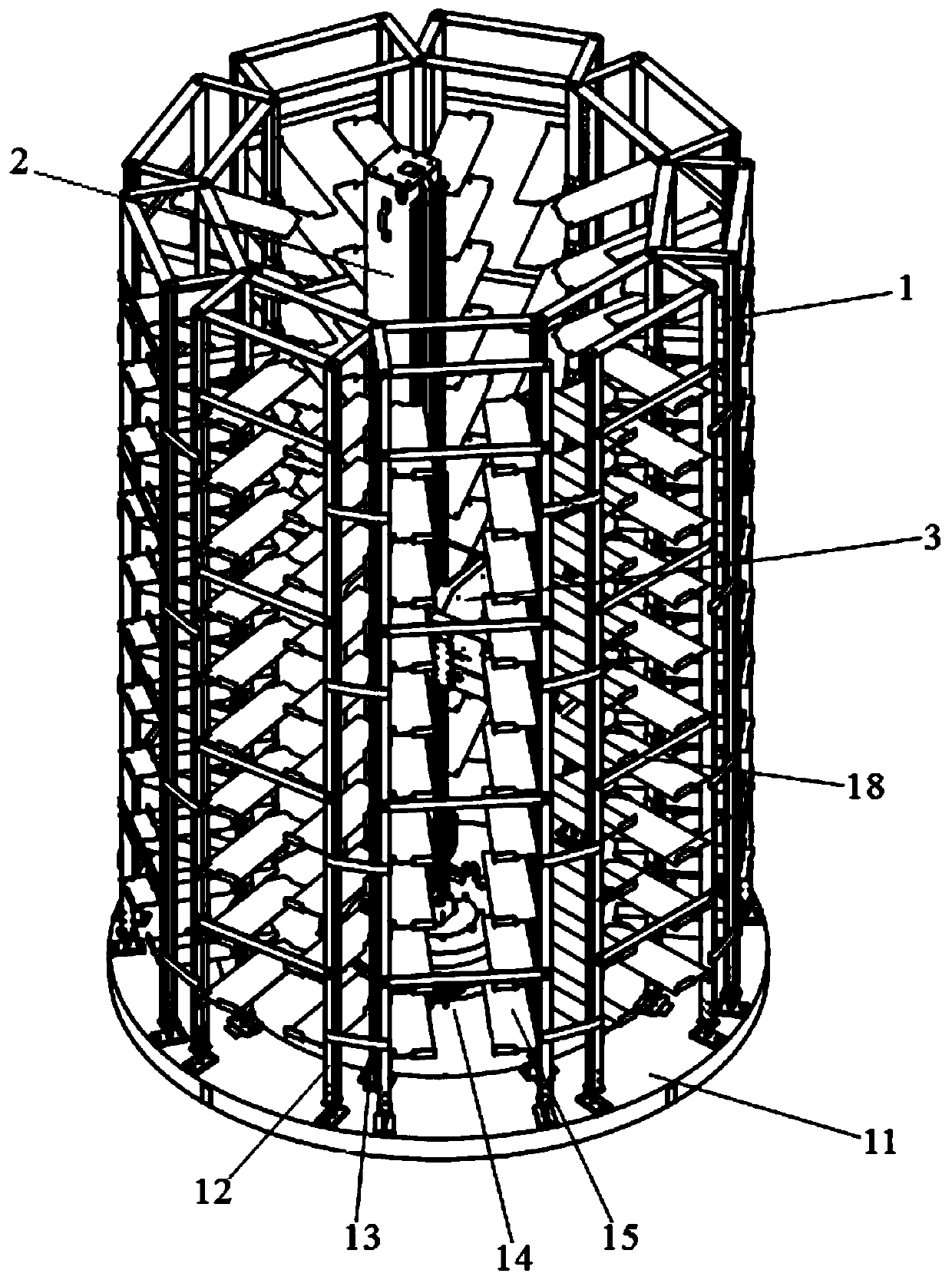

[0038] Please refer to Figure 1-Figure 11 , the present embodiment is a fully automatic ring-shaped three-dimensional storage device 100 with a sorting function, which includes a ring-shaped three-dimensional warehouse 1, a rotating lifting device 2 arranged at the central position of the ring-shaped three-dimensional warehouse 1, and a cargo cage device arranged at the movable end of the rotating lifting device 2 3. One end is inserted into the annular three-dimensional warehouse 1 from the bottom and the conveying device 4 docked with the cargo cage device 3, the robot clamping device 5 arranged next to the conveying device 4, and the material on the conveying device 4 is transported to the designated position AGV smart car6.

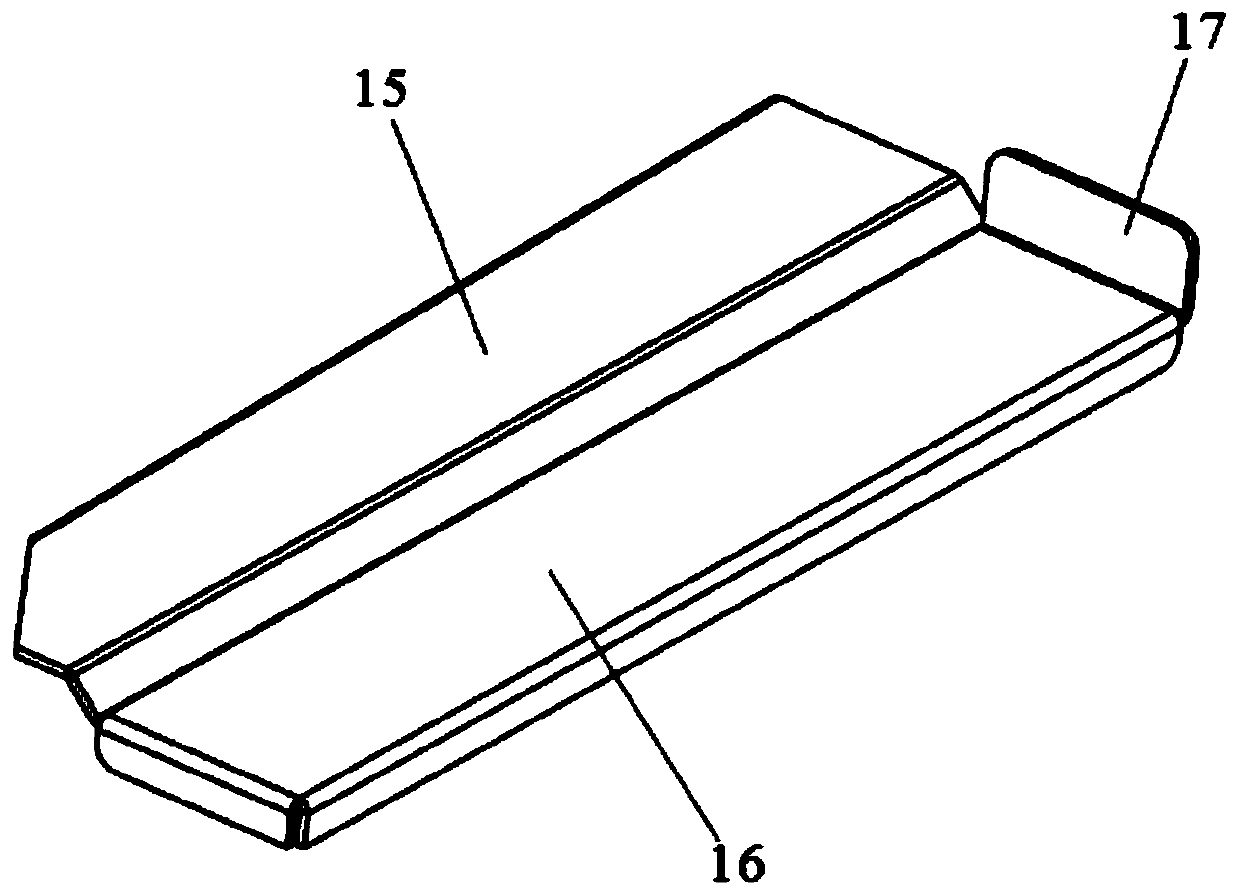

[0039] The annular three-dimensional warehouse 1 includes an annular chassis 11, an outer ring column 12 and an inner ring column 13 which are annularly arranged on the annular chassis 11, and two adjacent outer ring columns 12 and two inner ring col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com