Water flushing vibroflotation machine

A vibrator and water flushing technology, applied in construction, sheet pile wall, foundation structure engineering, etc., can solve problems such as poor convenience of use, and achieve the effect of improving piling speed, convenient use and reducing inclination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

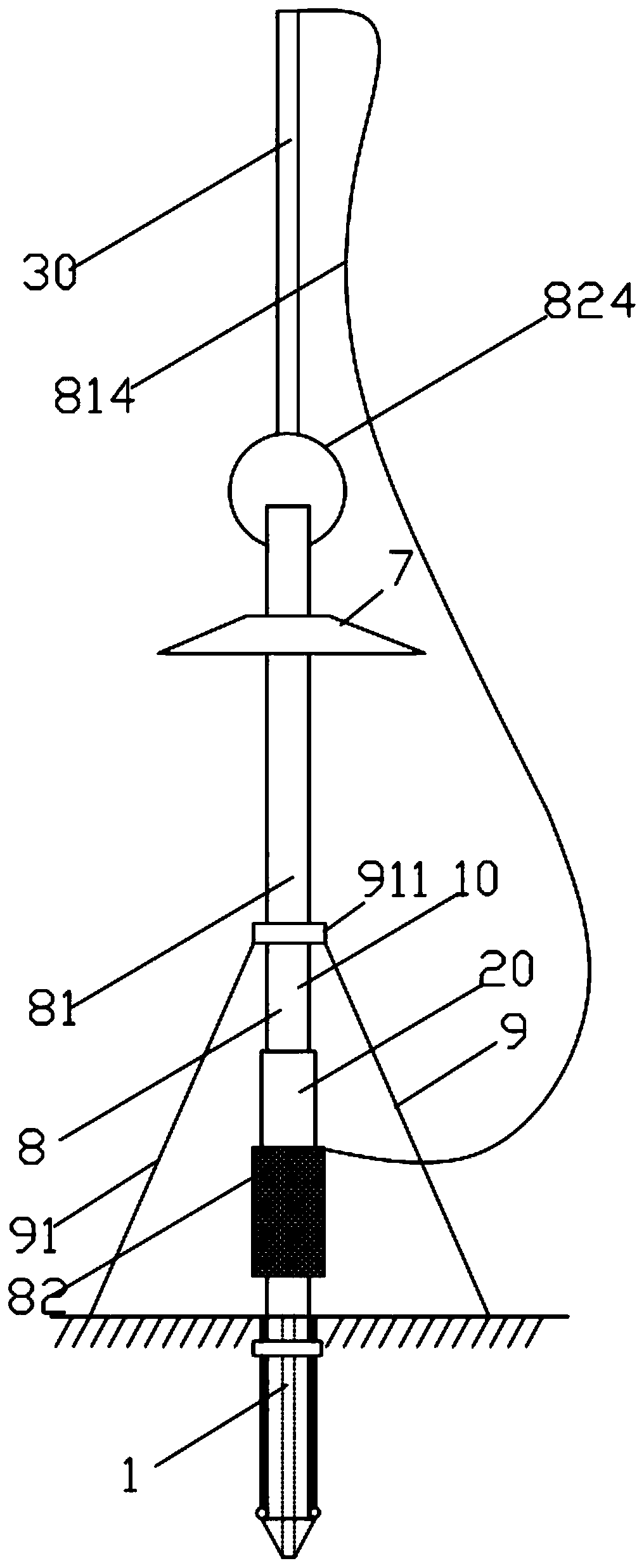

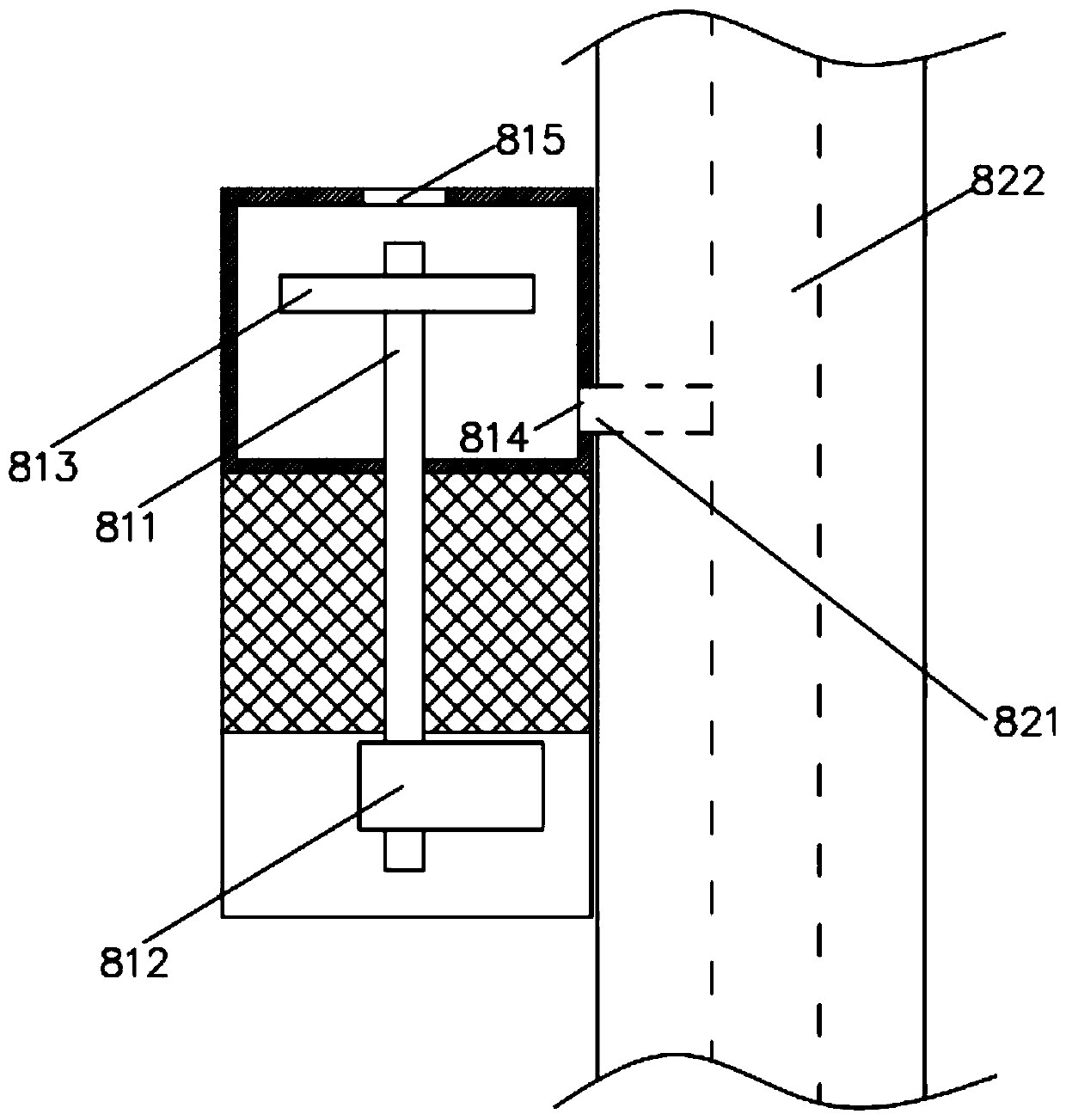

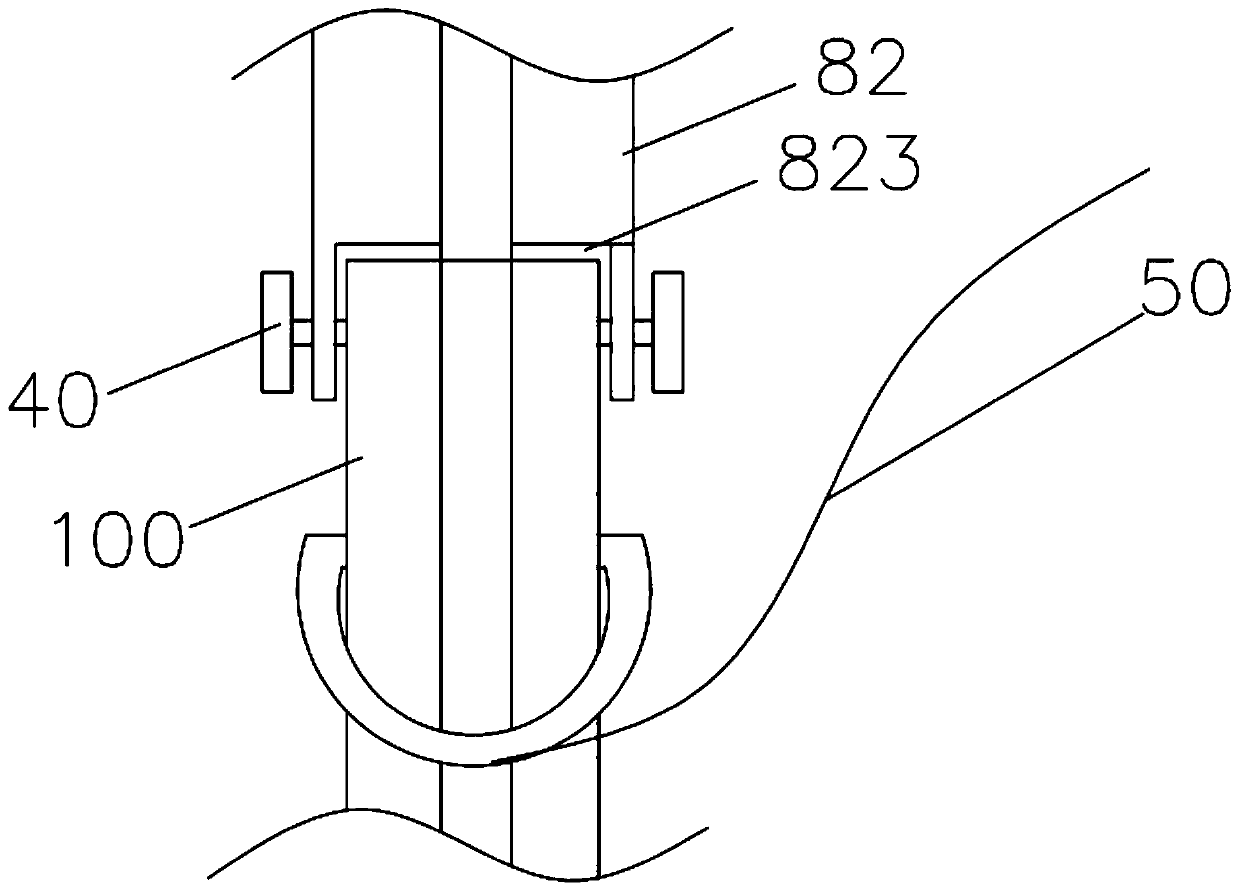

[0024] Such as Figure 1 to Figure 7 As shown, a kind of water flushing vibrator of the present embodiment comprises a gravity rod 82 and a vibrating submersible pump 81. The vibrating submersible pump 81 is arranged on the gravity rod 82. The vibrating submersible pump 81 is provided with a cable 814. An anchor bayonet 823 is provided at the bottom, and the vibrating submersible pump 81 has a water outlet 814 and a water inlet 815. The water outlet 814 of the vibrating submersible pump 81 communicates with the water inlet 821 of the gravity rod 82, and there is a fluid channel 822 in the gravity rod , the fluid channel 822 communicates with the water inlet hole 821 . In the above technical solution, by setting the gravity rod, gravity can be provided to reduce the inclination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com