A screw pile driver

A technology of pile driver and screw rod, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of inconvenient transportation of the project and occupy a large area, so as to save the hoist, save the space of the construction site, and improve the speed of piling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

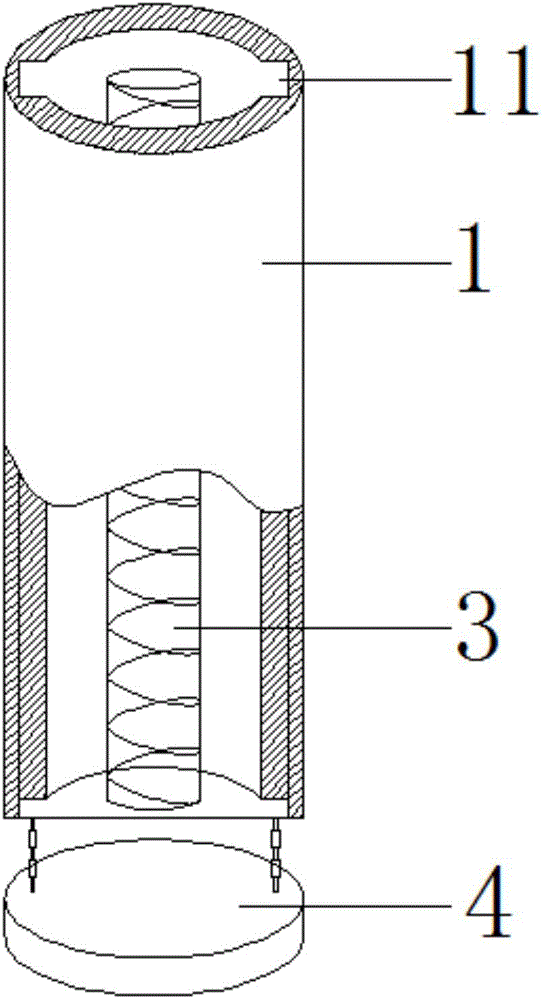

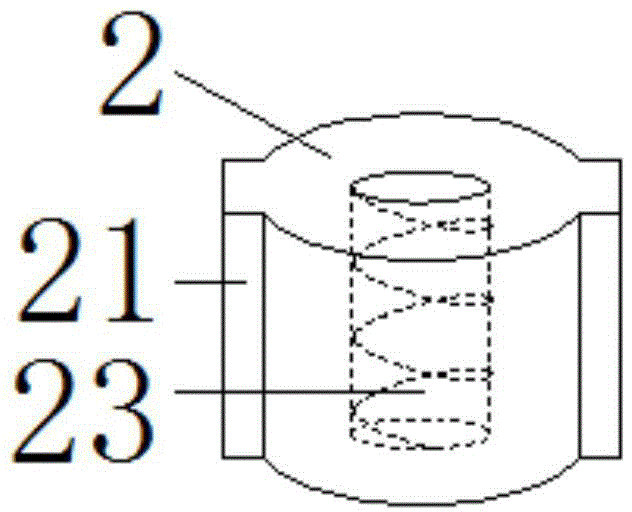

[0013] by figure 1 , figure 2 In the shown embodiment, the screw pile driver includes a cylindrical pile frame 1 and a pile hammer 2; A screw 3 extending along the axis is installed on the 1 axis, and the rotation of the screw 3 is driven by a driving motor; a screw hole 23 matching the screw 3 is provided along the axis of the pile hammer 2, and the pile hammer 2 The outer surface has ribs 21 matching the slots 11 on the inner wall of the pile frame 1 . A metal chain is used to connect a hard backing plate 4 at the bottom of the pile frame 1; an oil storage structure containing lubricating oil is arranged on the top of the screw rod 3 and the inner wall of the pile frame 1.

[0014] The pile hammer 2 is limited by the draw-in groove 11 of the pile frame 1 inner wall, and cannot rotate along the axis, but can only produce displacement in the vertical direction; during construction, start the drive motor, and the drive motor drives the screw mandrel 3 to accelerate rotation;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com