Decoration leveling assembly and house decoration structure

A technology of leveling and components, which is applied in the direction of building structure, floor, covering/lining, etc., can solve the problems of prolonging the construction period, increasing the construction cost, and the flatness of the decoration layer can not be better guaranteed, so as to save decoration Time saving, installation time saving, and installation cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

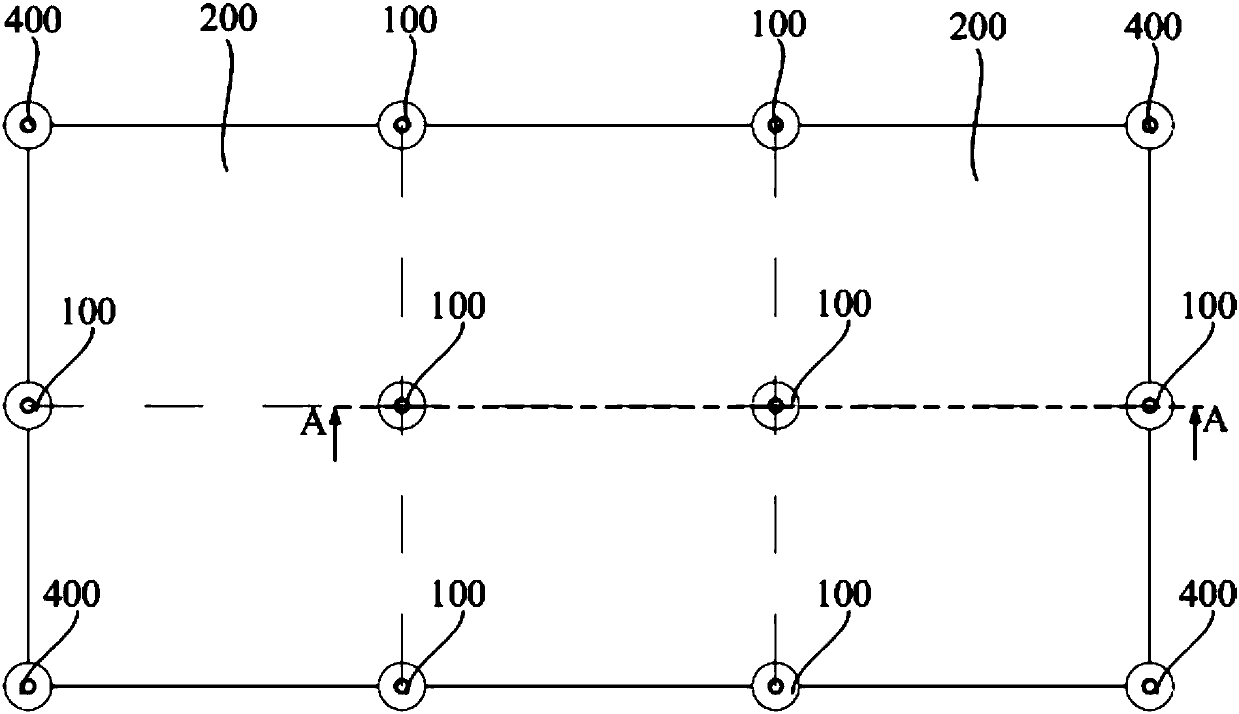

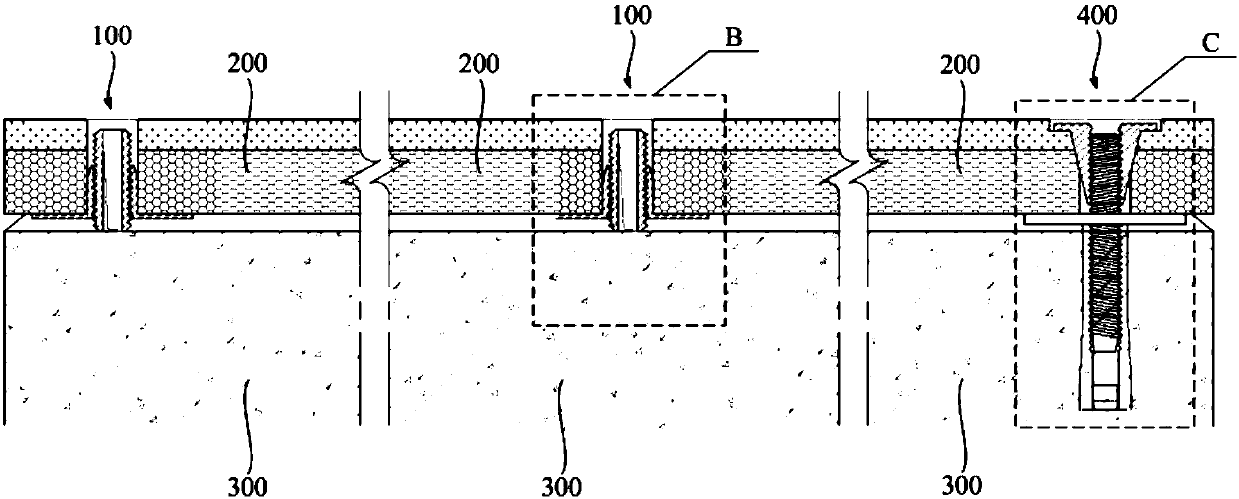

[0036] refer to figure 1 , figure 2 In the process of house decoration, the main decoration material 200 (such as the thermal insulation layer laid on the ground, the decorative board installed on the wall, etc.) needs to be fixedly installed on the part to be decorated 300 (such as the rough floor, the rough wall, etc.). In order to make the decorated floor or wall have a better appearance, it is also necessary to level the main decoration material 200 after the fixed installation.

[0037] In this embodiment, the main decoration material 200 is firstly fixed to the part to be decorated 300 by the decoration fixing member 400 ; after the main decoration material 200 is fixedly installed, the decoration and leveling component 100 is used to level the decoration component 200 to Avoid unevenness or inclination of the main decoration materials, so that the floor or wall after decoration has a better appearance.

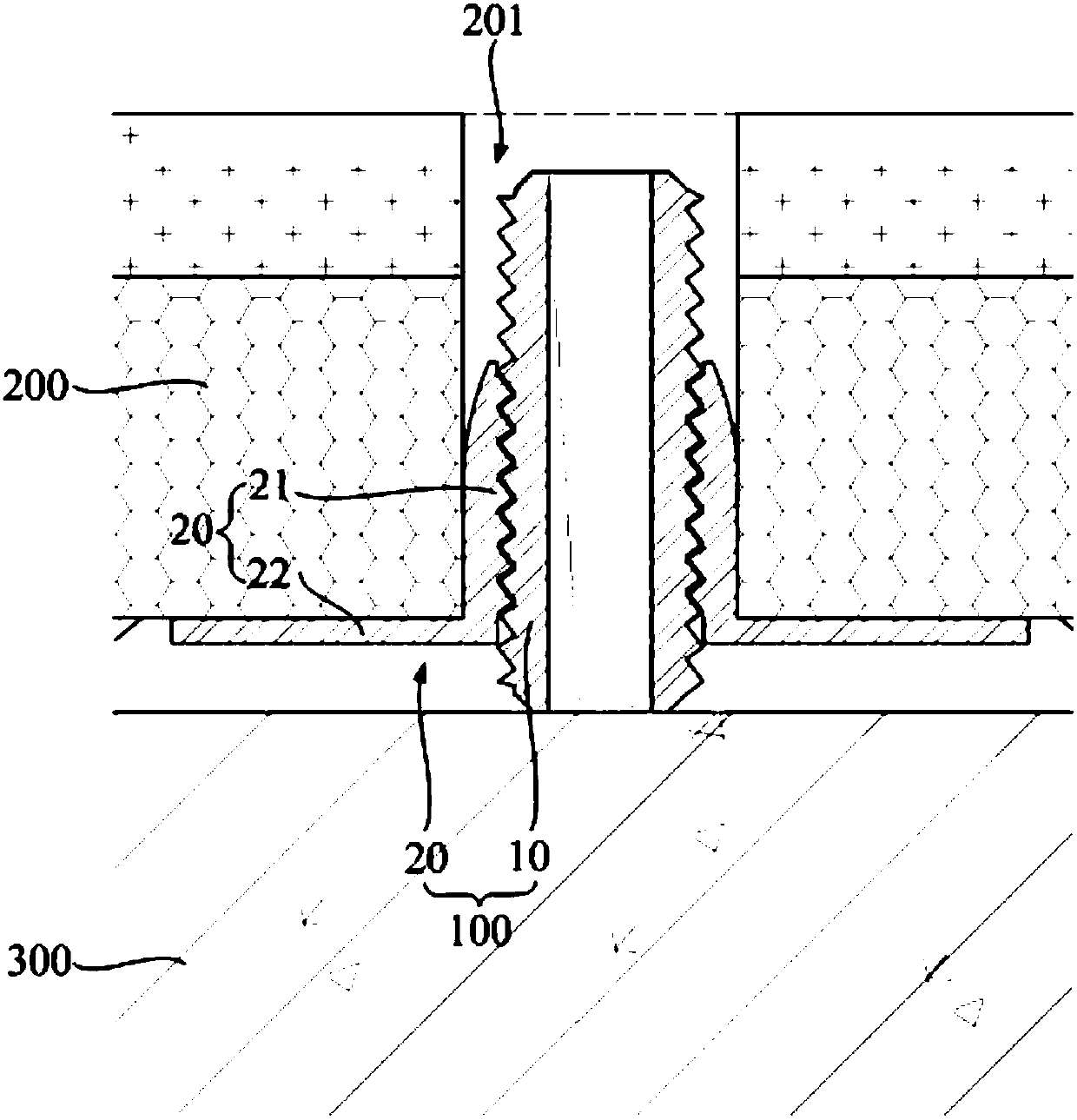

[0038] refer to image 3 , this embodiment provides a decorati...

no. 2 example

[0065] refer to Figure 7 , Figure 8 The difference between this embodiment and the first embodiment is that the decoration and leveling assembly 100 further includes a gasket 30, and the gasket 30 is arranged at one axial end of the leveling rod 10, and the leveling The rod 10 is in contact with the to-be-fitted part 300 through the washer 30 .

[0066] In order to make the main decoration material 200 have a better appearance, the mounting holes 201 on the main decoration material 200 are generally small, and the leveling rod 10 inserted into the mounting hole 201 is also relatively thin. As opposed to the to-be-fitted portion 300 , during the leveling process, the rotation of the leveling rod 10 can easily damage the surface of the to-be-fitted portion 300 , resulting in a groove at the contact position of the leveling rod 10 .

[0067] By arranging the gasket 30 between the to-be-fitted part 300 and the leveling rod 10 , the gasket 30 and the surface of the to-be-fitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com