Bracket for construction of shotcrete anchor net support in broken area in high seismic zone

A technology of spray anchor net and seismic zone, applied in underground chambers, shaft equipment, wellbore lining, etc., can solve the problems of not being able to spray anchor net at the required place, reducing the use efficiency of the device, and reducing the strength of spray solidification, etc. Avoid carrying heavier weight at one time, increase the efficiency of use, and reduce the effect of concrete solidification strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

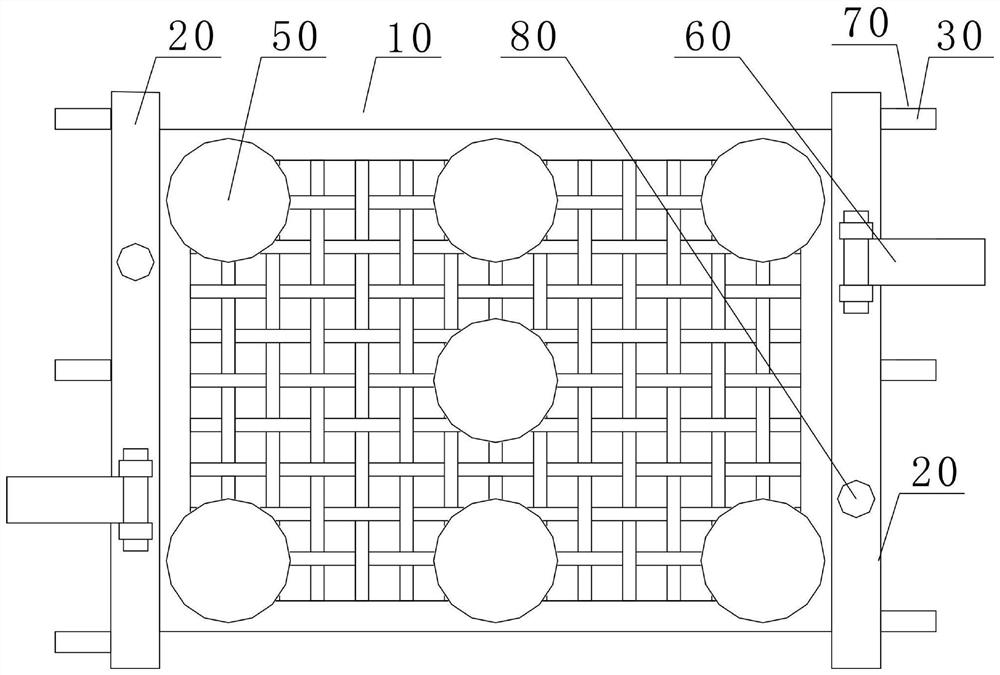

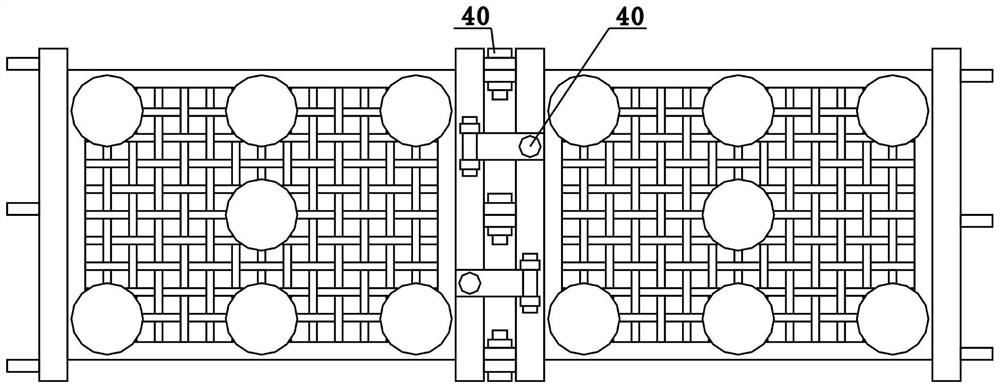

[0036] like Figure 1-3 As shown, the embodiment of the present invention discloses a support for spraying anchor net support construction used in the broken area of the high seismic zone, including at least one support unit, and the support unit and the support unit can be fixedly connected arbitrarily. Specifically,

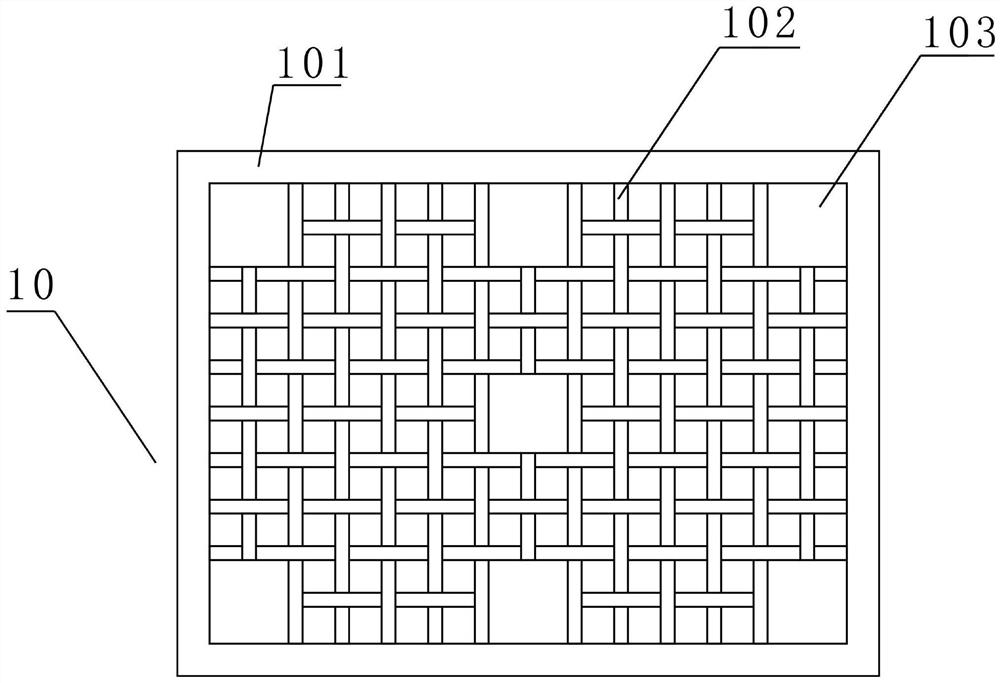

[0037] The bracket unit includes spray anchor net 10 , bracket bar 20 , limiting plate 30 , positioning nut 40 and insertion rod 50 . The sprayed anchor net 10 is composed of a sprayed anchor net main frame 101 arranged on the periphery and a number of reinforcement ribs 102 arranged at intervals in the spray anchor net main frame 101. A number of reinforcement ribs 102 form a reinforcement net, and a plurality of ribs are evenly arranged on the reinforcement net. The mesh 103 and the inserting rod 50 are evenly inserted in the mesh 103 of the reinforcement mesh, so that the spray anchor mesh 10 is conveniently fixed at the required place to prevent slipping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com