Rapid dynamic balancing method of pumped storage unit based on precise test weight combined with influence coefficient method

A technology of pumped storage unit and influence coefficient method, which is applied in static/dynamic balance test, machine/structural component test, instrument, etc., can solve the problems of high cost, waste of time and expense, long time, etc., and achieve reduction Small vibration, fast and effective effect of dynamic balance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

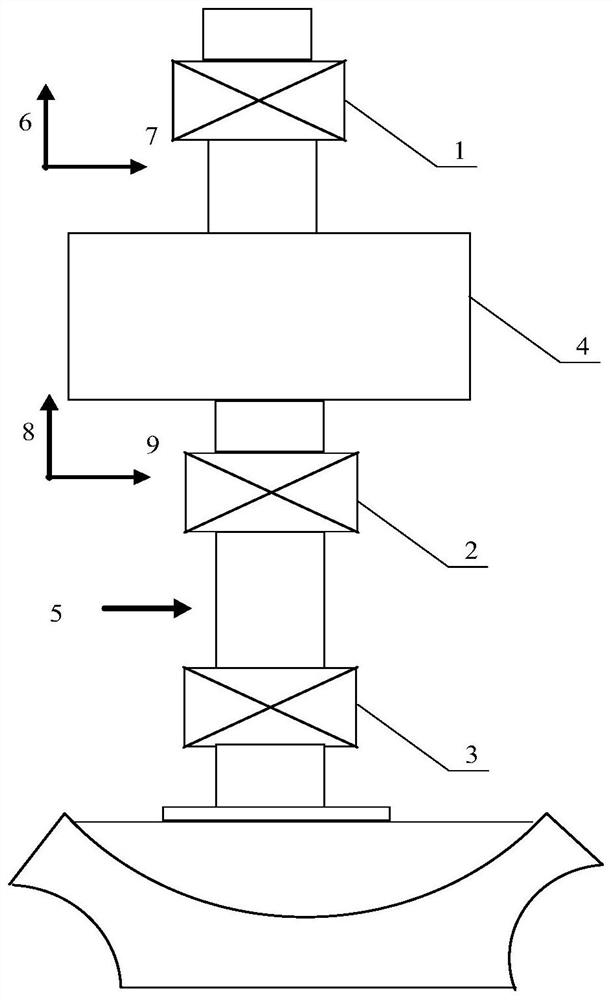

[0044] Such as figure 1 with figure 2 As shown, a rapid dynamic balancing method for pumped storage units based on precise test weight combined with influence coefficient method includes the following steps:

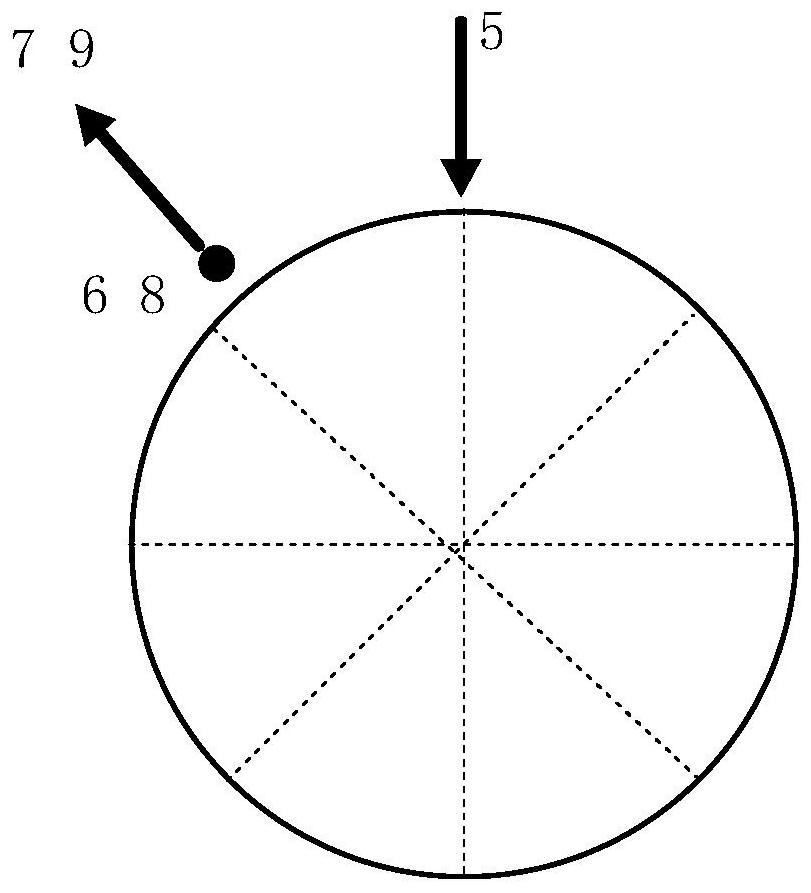

[0045] (l) Installation of measuring points before unit start-up: Install vertical vibration sensor 6 on upper frame, horizontal vibration sensor 7 on upper frame, vertical vibration sensor 8 on lower frame, and vertical vibration sensor 8 on lower frame before starting the unit. The horizontal vibration sensor 9 is used to measure the vibration at the upper guide bearing 1 and the lower guide bearing 2. A photoelectric sensor 5 is installed on the exposed journal surface of the upper cover of the water guide bearing 3, and a reflective tape is pasted on the generator rotor 4 here to measure the phases of the horizontal and vertical vibrations of the upper frame and the lower frame;

[0046] (2) The unit slowly opens the guide vanes to increase the speed under the wor...

Embodiment 2

[0071] The present invention will be further described below by taking the field dynamic balance test of No. 4 generating set of a certain pumped storage power station as an example.

[0072] 1) First arrange the measuring points, a total of 5 measuring points are arranged, including: vertical vibration sensor 6 on the upper frame, horizontal vibration sensor 7 on the upper frame, vertical vibration sensor 8 on the lower frame, and horizontal vibration sensor 9 on the lower frame. A photoelectric sensor 5 is installed on the exposed journal surface of the upper cover of the guide bearing 3, and a reflective tape is pasted on the generator rotor 4 here to measure the vibration phase of the upper frame and the lower frame. See figure 2 .

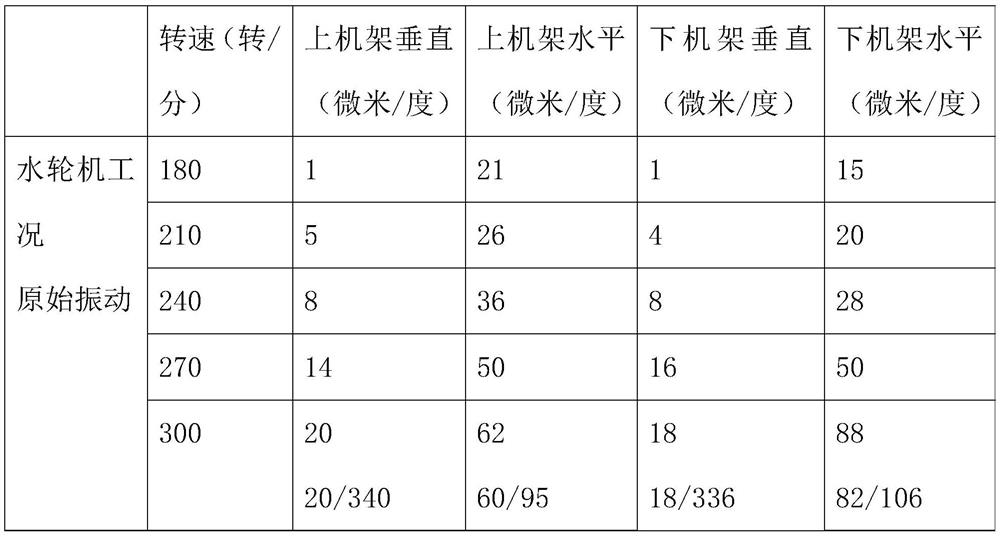

[0073] 2) Test the original vibration condition of the unit, stabilize the speed of the unit at 60%, 70%, 80%, 90% and 100% of the rated speed respectively, and use a vibration tester to record the upper and lower racks of the unit at differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com