Total silicone lipstick mould removing machine

A release machine and silicone mold technology, applied in the types of packaging items, applications, special packaging items, etc., can solve the problems of unstable lipstick product quality, low labor efficiency, low production efficiency, etc., to achieve convenient automatic transportation and ensure normal operation. Progressive, clear surface texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with accompanying drawing and by specific embodiment, should point out: for the common craftsman in this technical field, under the premise of not departing from the principle of the present invention, the modification of various equivalent forms of the present invention all fall within the scope defined by the appended claims of this application.

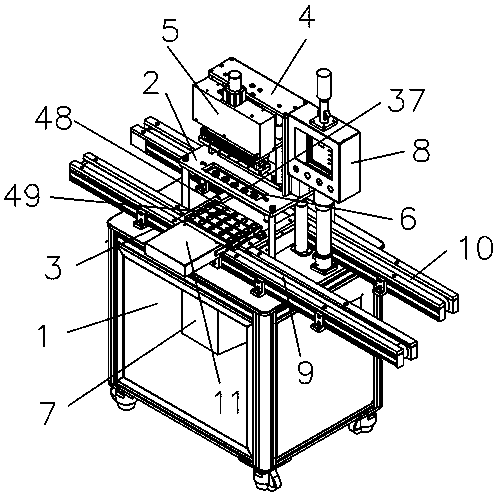

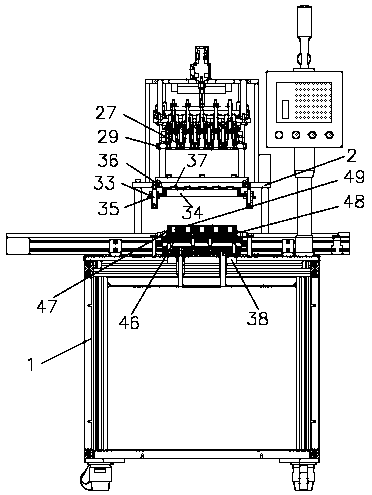

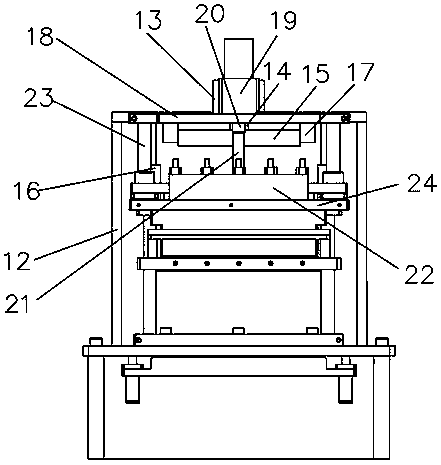

[0022] Such as Figure 1-6 As shown, a lipstick full silicone demoulding machine, including: frame 1, support frame 2, lower mold moving mechanism 3, upper mold lifting mechanism 4, upper mold clamping mechanism 5, middle mold lifting mechanism 6, lower mold lifting mechanism Mechanism 7, controller 8, a support frame 2 is provided on the middle side of the frame 1, a lower mold moving mechanism 3 is provided on both sides of the frame 1, and an upper mold lifting mechanism is provided at the rear end of the support frame 2. Mechanism 4, the upper mold li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com