Dust removal device with vibration function for building material workshop

A dust removal device and workshop technology, applied in the direction of dust removal, cleaning methods and appliances, and separation of dispersed particles, can solve problems affecting the filtration quality, on-site chaos, and affecting the quality of the working environment, so as to improve practicability, improve dust removal quality, The effect of ensuring the quality of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

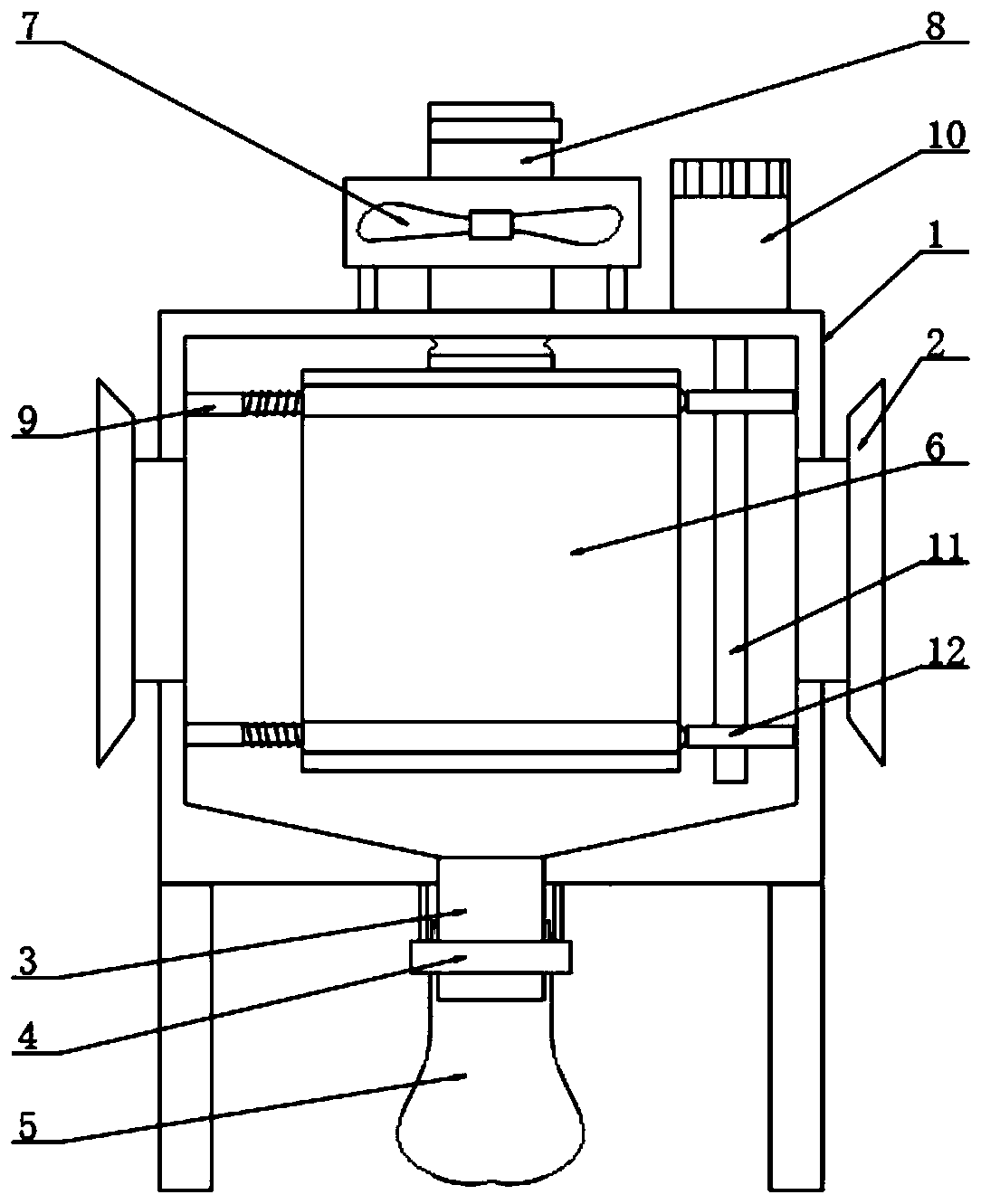

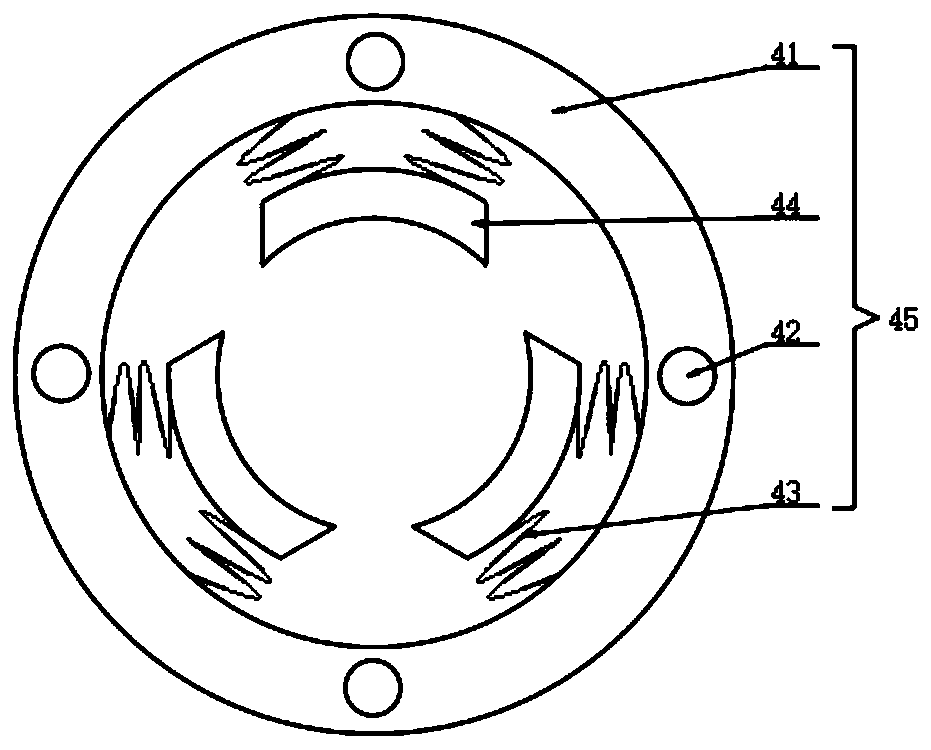

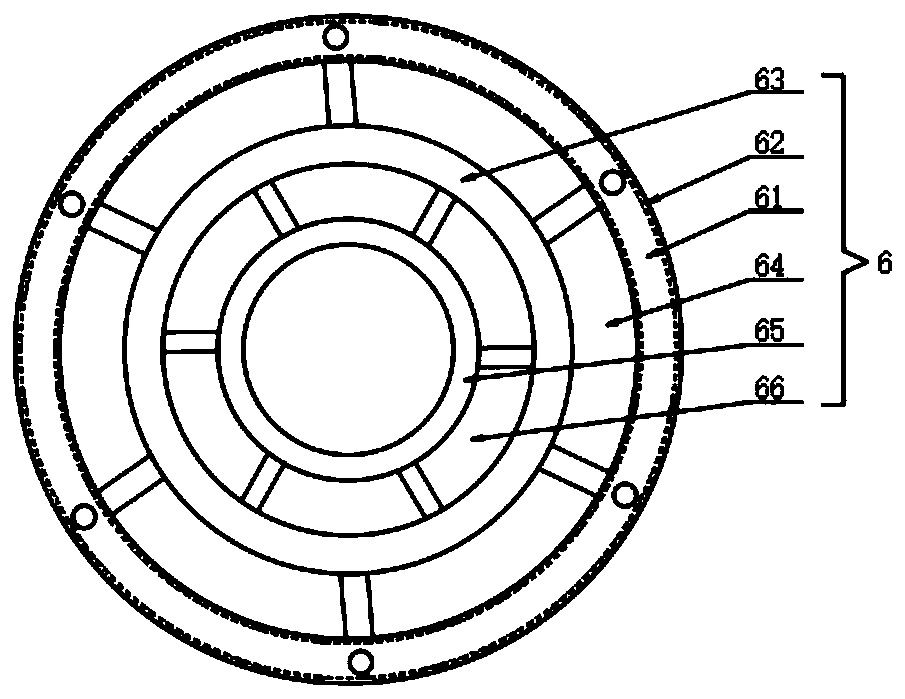

[0022] Example: When in use, the axial flow fan 7 is turned on, and the axial flow fan 7 forms a negative pressure in the dust removal housing 1, so that the dust inlet bell mouth 2 is opened to absorb the air in the building material space, and the air flows inward through the coarse filter 61, The fine filter 63 and the activated carbon filter 65 perform dust removal and purification, and the dust blocked by the outer wall of the coarse filter 61, the fine filter 63 and the activated carbon filter 65 falls down to the bottom of the dust removal housing 1, and the purified air is softened by the connection The pipe and the exhaust pipe 8 are discharged outwards. At the same time, the drive motor 10 can be started to rotate, and the drive motor 10 drives the rotating rod 11 to rotate, so that the two sets of cams 12 push the filter 6 to move to the left and squeeze the elastic telescopic rod 9. When the protruding end of 12 is not in contact with the filter element 6, the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com