Full yarn shearing mechanism

A technology of full yarn and scissors, which is applied in the cutting of textile materials, textile and papermaking, and the transportation of filamentous materials, etc. It can solve the problems of yarn grabbing failure and other problems, and achieve the effect of reasonable structure, simple design and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

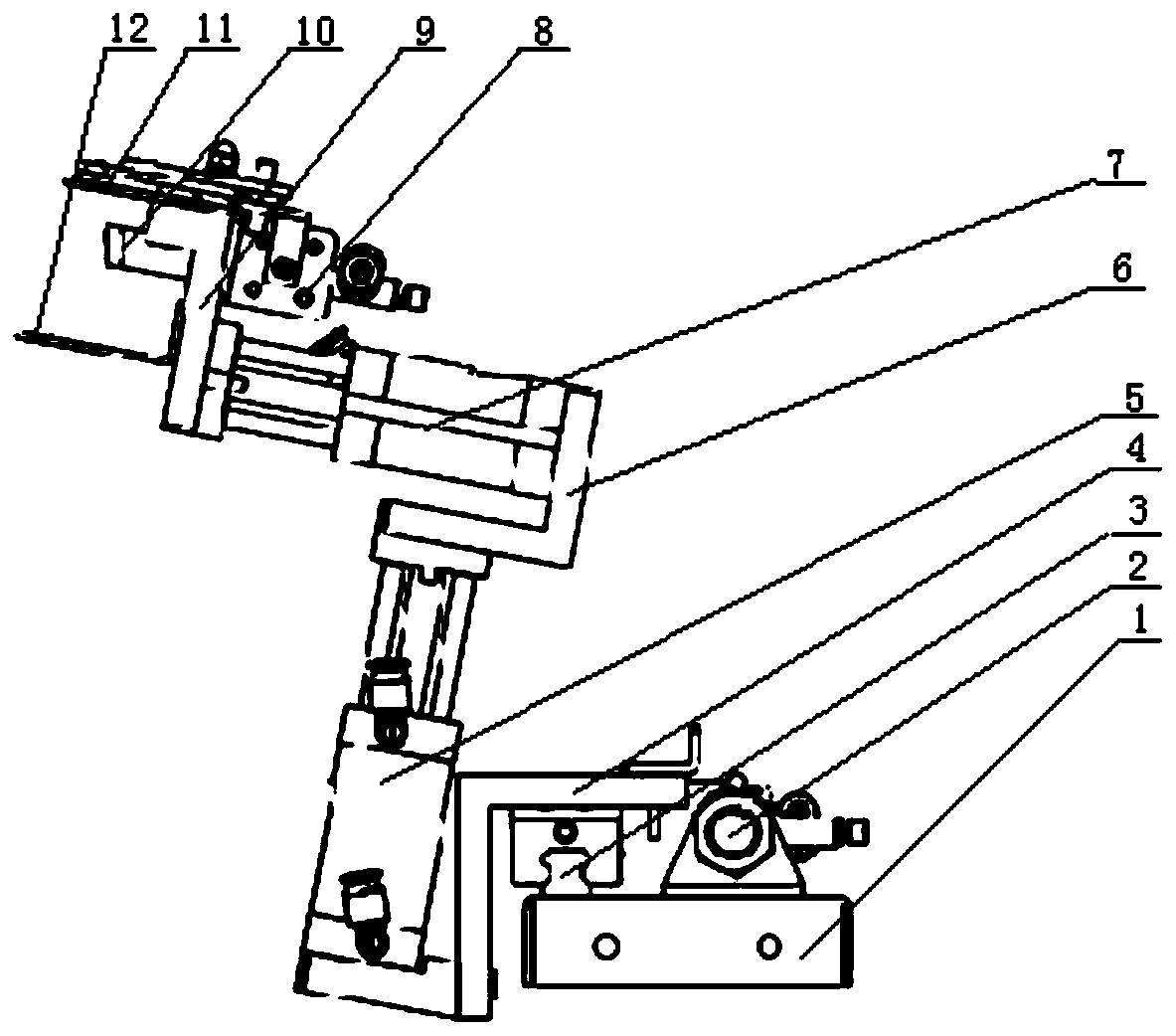

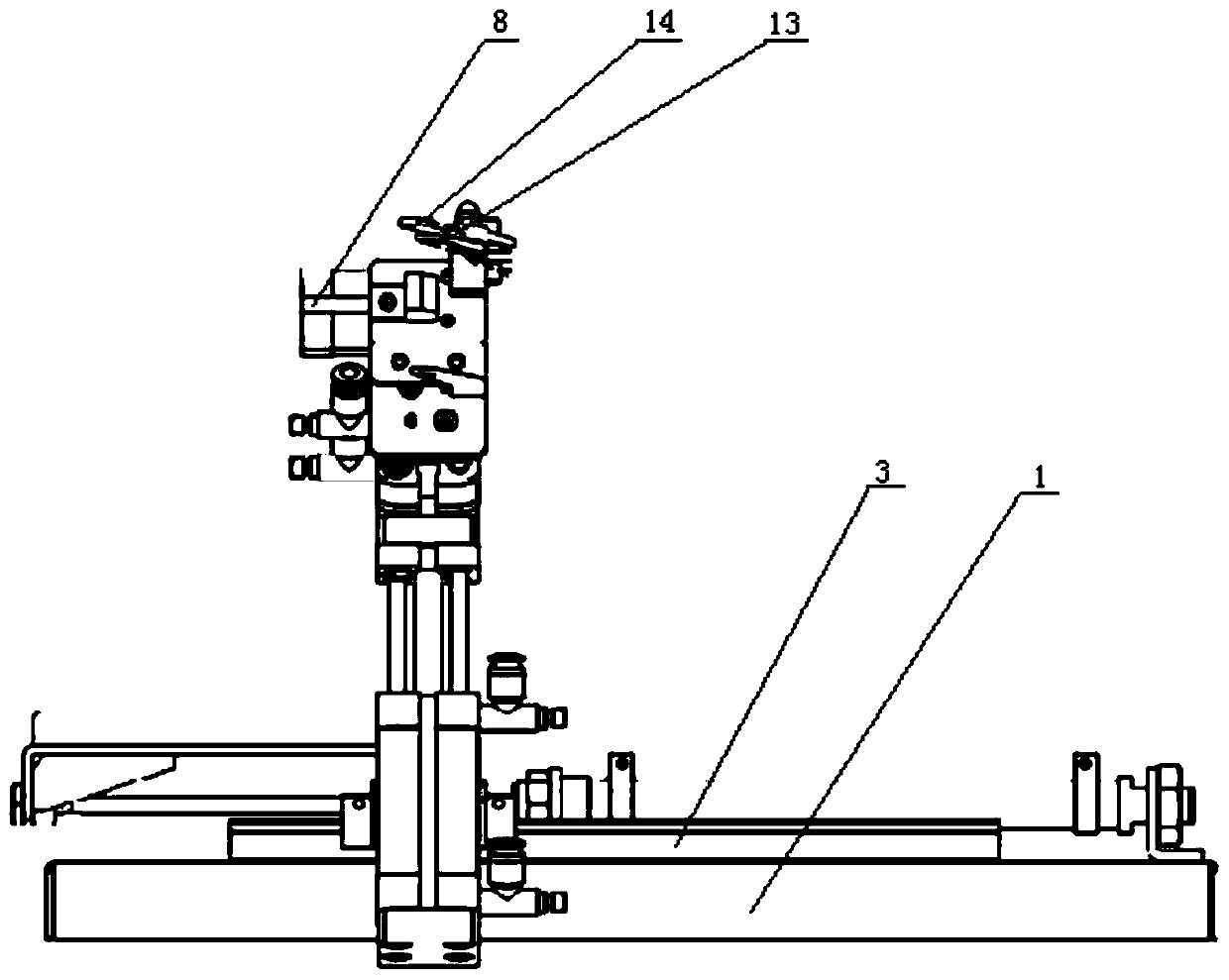

[0013] refer to Figure 1 to Figure 2 The specific implementation of a full yarn cutting mechanism of the present invention will be further described.

[0014] A full yarn cutting mechanism, comprising a base plate 1, the base plate 1 is provided with a guide rail 3 along the transverse direction, a connecting plate-4 is slidably connected to the guide rail 3, and the connecting plate-4 is provided on the base plate 1 to drive Sliding driving device one 2, the connecting plate one 4 is connected with a vertical cylinder one 5, the top of the cylinder one 5 is fixedly connected with a connecting plate two 6, and the connecting plate two 6 is fixedly equipped with a cylinder Two 7, the telescopic direction of the cylinder two 7 is perpendicular to the length direction of the base plate 1, the top of the cylinder two 7 is connected with a connecting plate three 9, and one side of the connecting plate three 9 is provided with a wire hook 10 and a suction Yarn port opening block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com