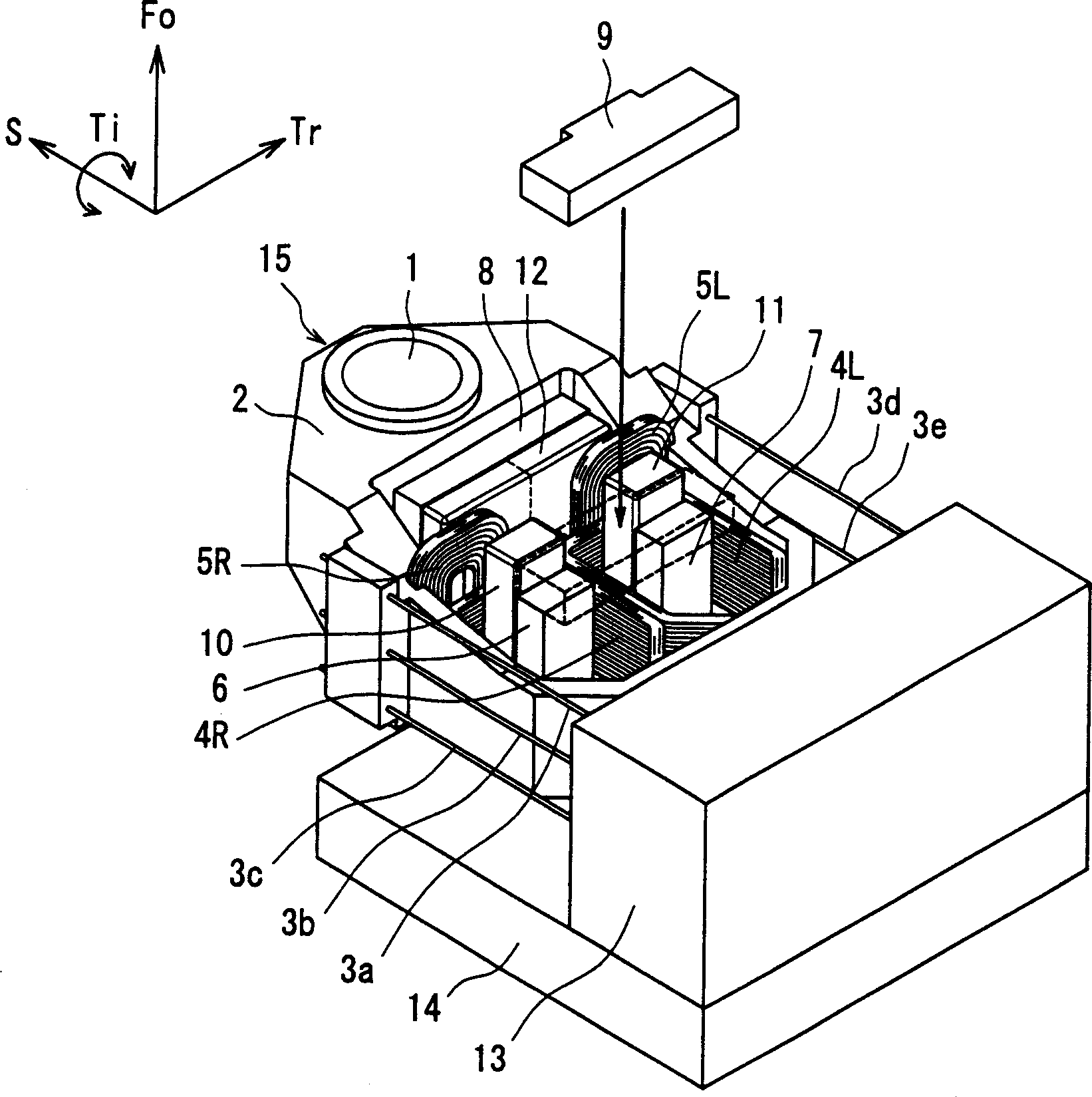

Objective lens drive device and optical disk device

A technology for a driving device and an objective lens, which is applied in the configuration/installation of the head, recording/reproducing by optical methods, instruments, etc., and can solve the problems of deterioration of light spot aberration, influence of recording and playback, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

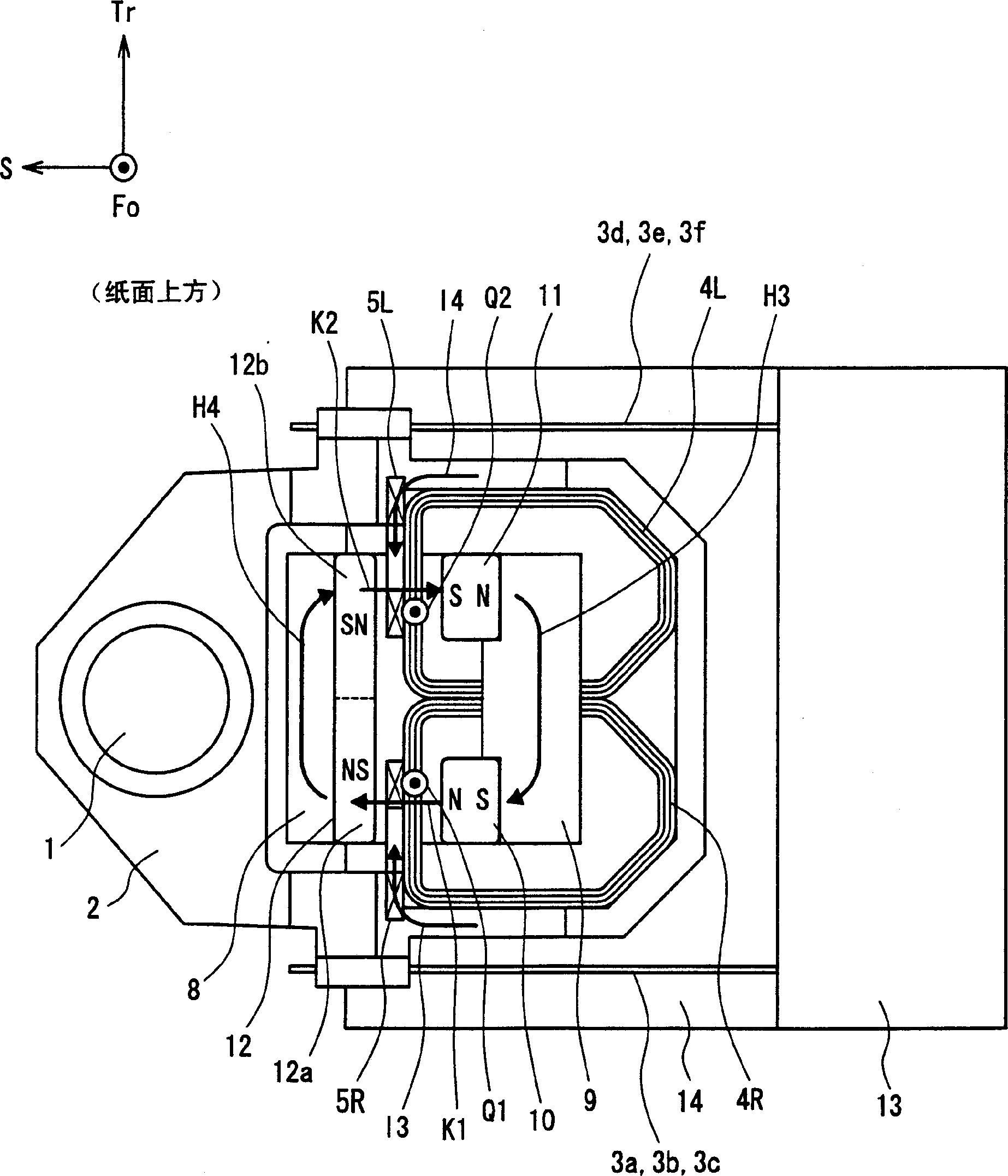

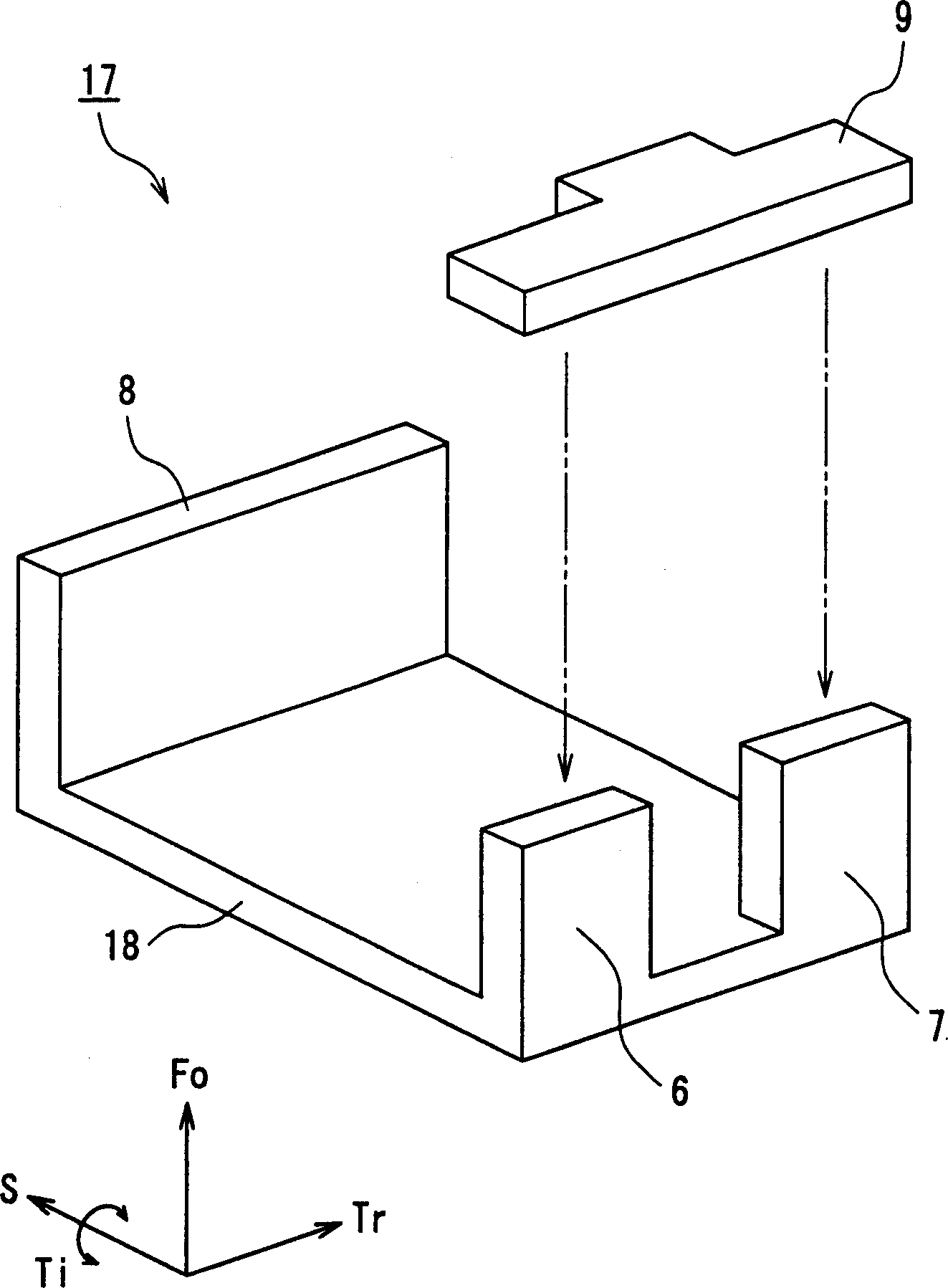

[0021] Since the objective lens driving device of the present invention has a bridge yoke connecting the open end of the first yoke and the open end of the second yoke, it is possible to prevent leakage that crosses the focus coil between the first yoke and the second yoke. Magnetic flux. Therefore, the pitch vibration of the movable part can be suppressed. In addition, since the magnetic utilization efficiency can be improved, the focus driving sensitivity can be improved.

[0022] In addition, because the bridge yoke is configured to not interfere with the tracking coil, the effective length of the tracking coil is not reduced, and the thickness of the objective lens driving device is not increased, and the tracking driving sensitivity can be improved.

[0023] In the objective lens driving device of the present invention described above, the third magnet and the fourth magnet are preferably held by a common third yoke arranged outside the magnetic gap, so that the generation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com