Device for detecting length and pile splicing quality of pre-stress concrete hollow pile and method of device

A technology of detection device and hollow pile, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of high cost of detection equipment, interference, inaccurate detection data, etc., and achieve the avoidance of cable vibration and consistent expansion range , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

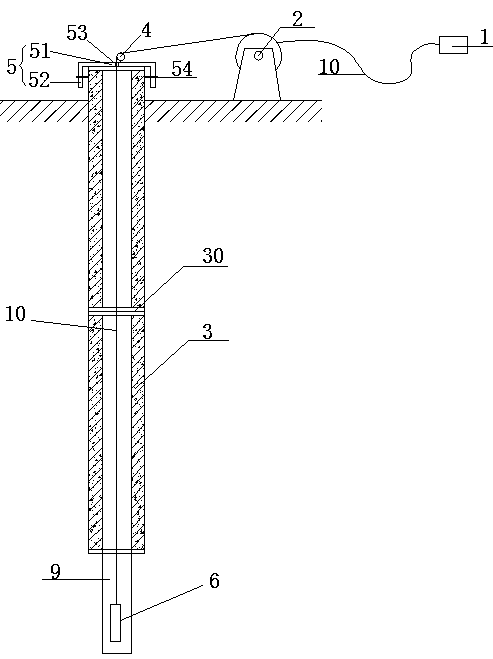

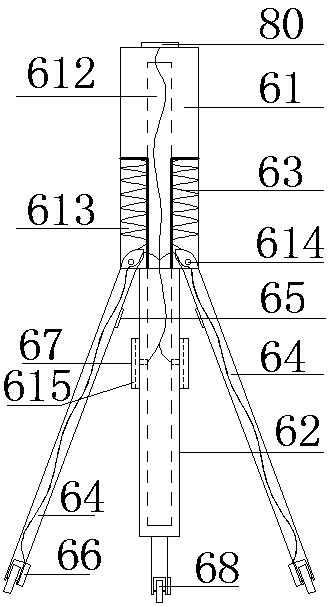

[0050] Embodiment 1: as Figure 1 to Figure 4 The shown prestressed concrete hollow pile length and pile connection quality detection device includes a detection instrument 1, a cable winch 2, and a hollow pile 3 located on the ground. The detection instrument 1 and the cable winch 2 are electrically connected through a cable 10, and also includes Counter 4, guide fixed cover 5, sensor 6 in the pile, described counter 4 is electrically connected to detection instrument 1 and is fixed on the guide fixed cover 5, and described guide fixed cover 5 is arranged on hollow pile 3 tops, and described pile inner sensor 6. Electrically connect with the detection instrument 1 through the cable 10;

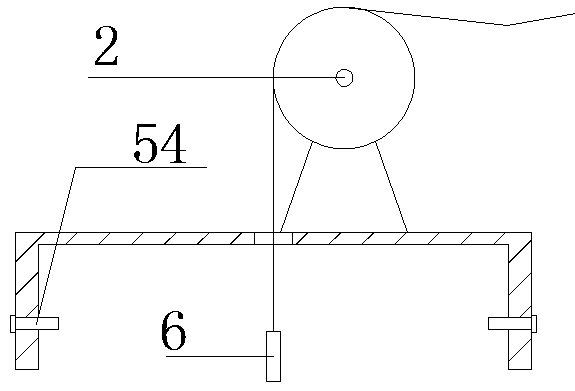

[0051] The guide fixed cover 5 is divided into a loam cake 51 and a side ring cover 52, the center of the loam cake 51 is provided with a cable through hole 53, and the side ring cover 52 is provided with a locking screw 54, which guides the guide fix cover 5 fixed on the top of the hollow p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com