equipment fault prediction and health assessment method based on a fuzzy Bayesian network

A Bayesian network and equipment failure technology, applied in the direction of specific mathematical models, predictions, calculation models, etc., can solve the problems of not considering the influence of the system, low accuracy of failure prediction, and failure to discover the interaction of single-machine equipment failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

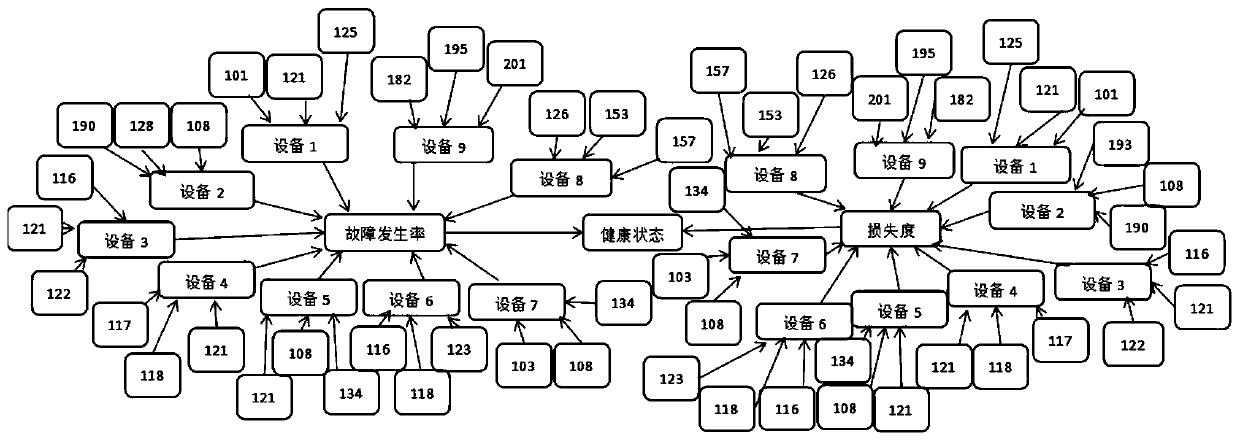

[0069] The following embodiment adopts the assembly line X of a household appliance enterprise from September 2017 to July 2018 a Data (there are 9 stand-alone devices on this assembly line), describe in detail the implementation process of the prediction method provided by the present invention.

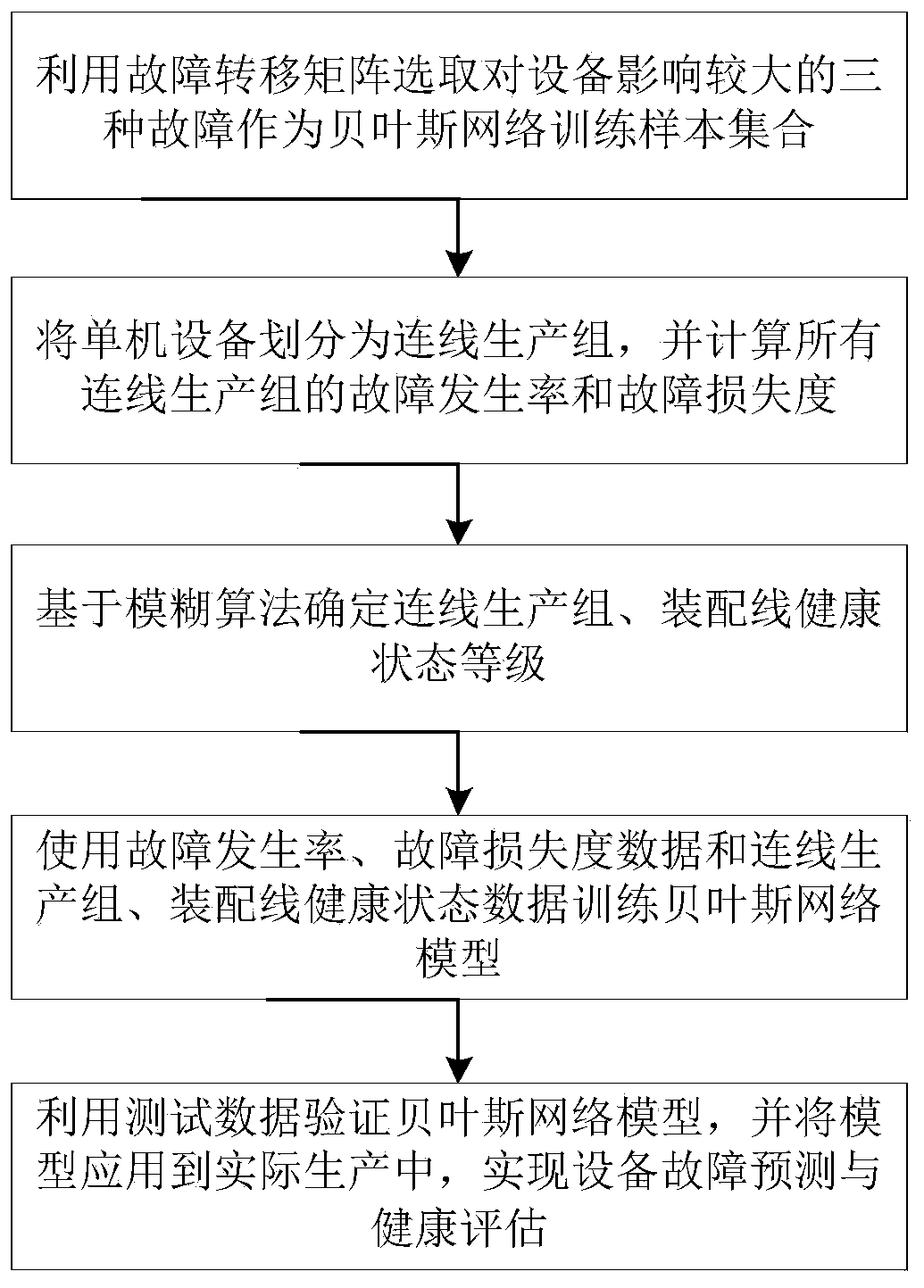

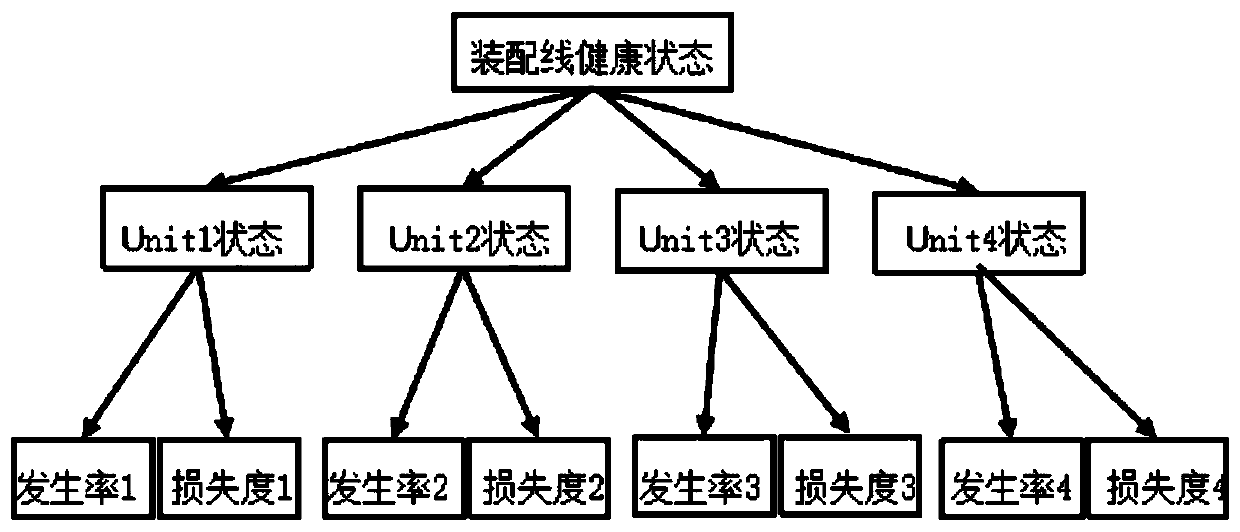

[0070] Method flow chart as figure 1 shown. The method of the present invention includes: 1) using the failover matrix to select three types of faults that have a greater impact on the equipment as a Bayesian network training sample set; 2) dividing the stand-alone equipment into on-line production groups, and calculating the Failure rate and failure loss degree; 3) Determining the health status level of connection production group and assembly line based on fuzzy algorithm; 4) Training Bayesian network ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com