An automatic coating device

A coating device and automatic spraying technology, applied in spraying devices, liquid spraying devices, transportation and packaging, etc., can solve the problems of large rail wear, manual wiping, and low operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0019] Embodiment: In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

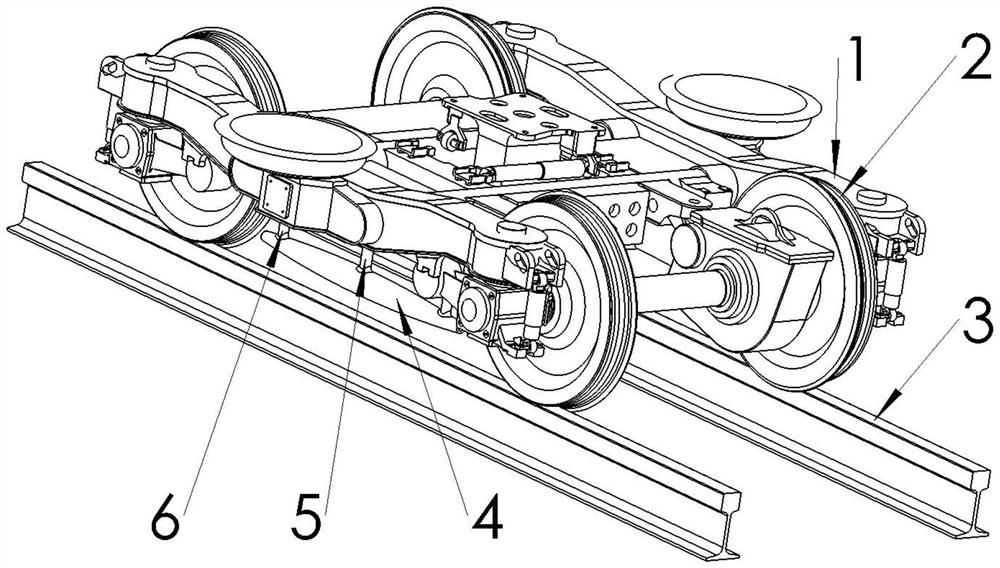

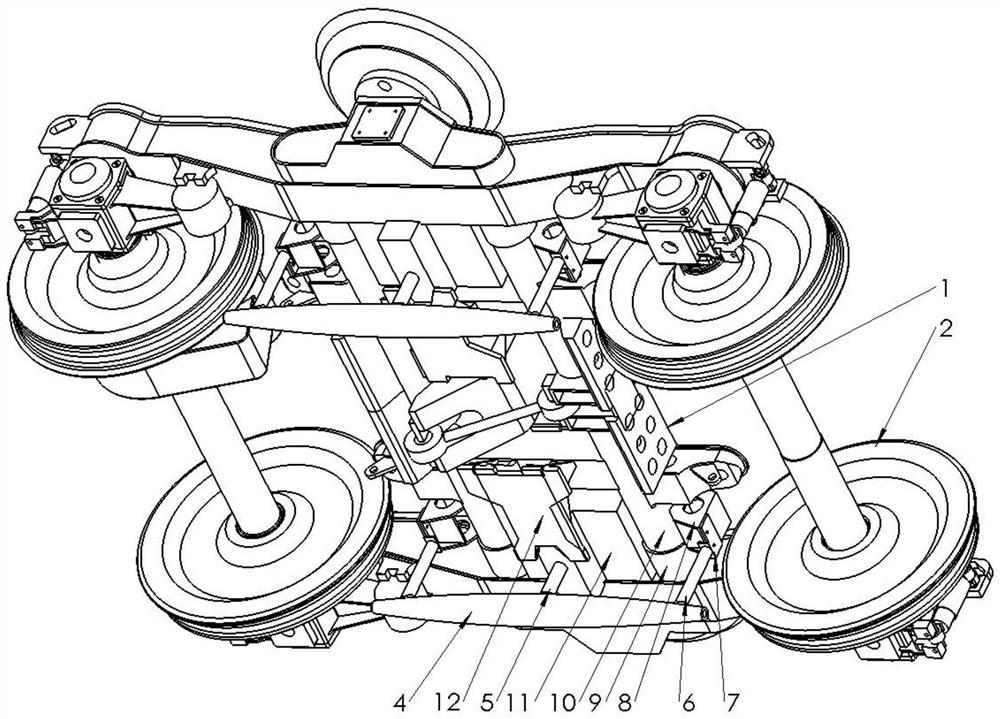

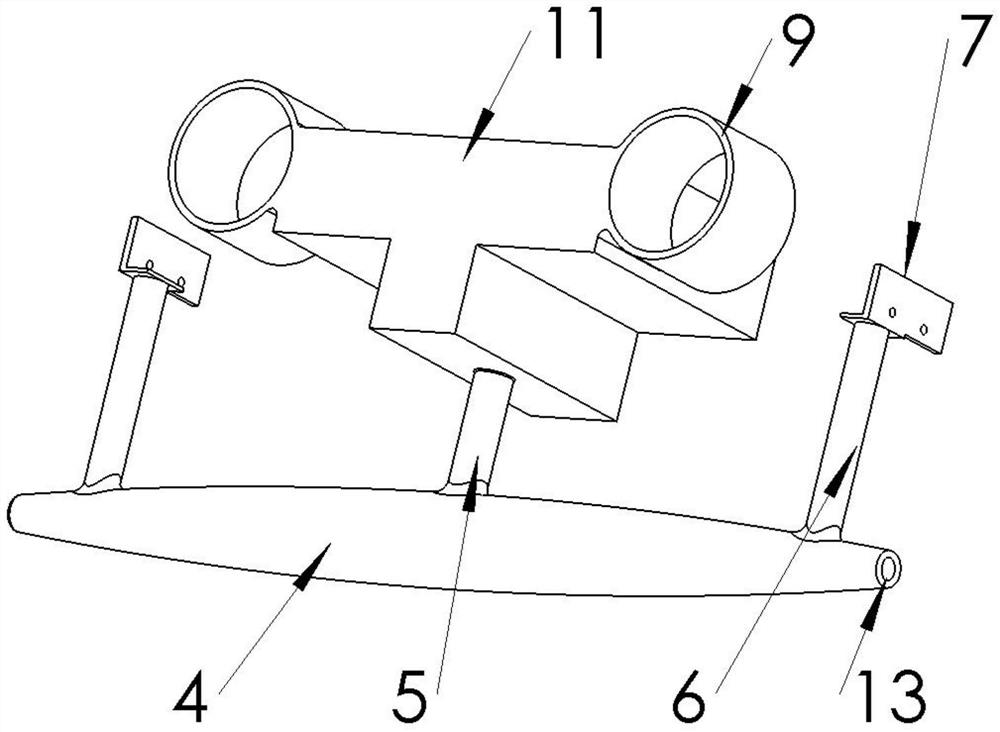

[0020] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of automatic coating device, is applicable to the automatic lubrication of the curved track of railway locomotive, and main structure comprises bogie 1, wheel 2 and rail 3, and bogie 1 is provided with four wheels 2 and is positioned at Rails 3 are provided on the left and right sides of the bottom of 1, the wheels 2 are pressed against the rails 3, and the center of the side beams on the left and right sides close to the bogie 1 are respectively provided with one-way feeding boxes 11, and the one-way feeding boxes The automatic spraying cylinder 4 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com