A kind of production method and production equipment of high-voltage damping wire

A technology for production equipment and damping wires, which is applied to equipment for manufacturing conductive/semiconductive layers, devices for coating liquid on surfaces, coatings, etc., which can solve the problems of increased labor costs, large floor space, and high production costs. problem, to achieve the effect of saving purchase cost, less manual operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

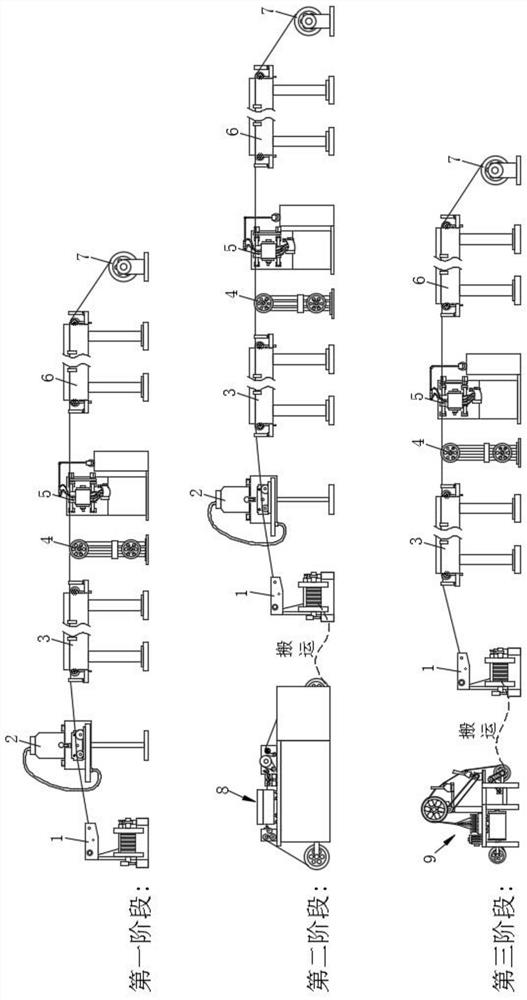

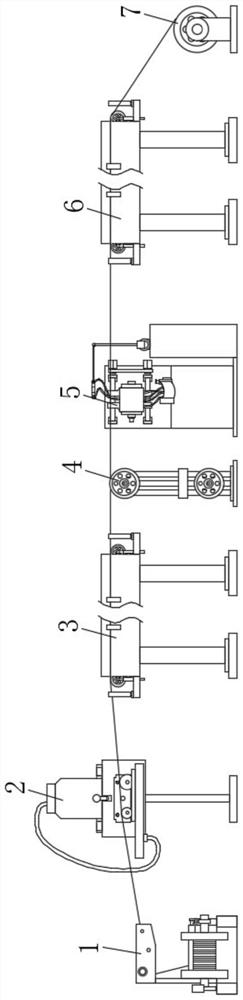

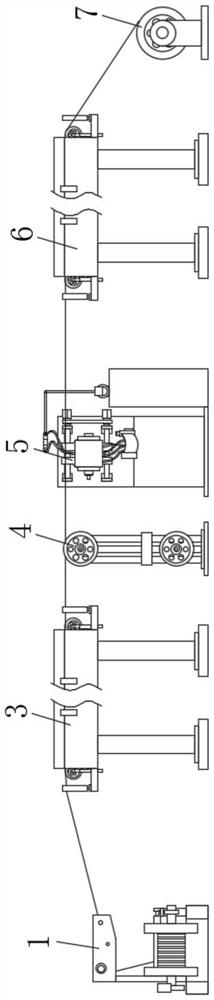

[0083] refer to figure 1 , this embodiment discloses a production method of a high-voltage damping wire, including three stages:

[0084] Phase 1 includes:

[0085] S1.1 Select spun yarn as the wire core, and place the wire core on the pay-off wheel of the pay-off device 1;

[0086] S1.2 The pay-off wheel pays off the wire, the wire core passes through the dipping device 2, and the outer surface of the wire core is dipped in the potion. The potion is a mixture of silica gel, magnetic powder and vulcanizing agent; the magnetic powder is used to resist the interference of other signals;

[0087] S1.3 The wire core stained with the liquid medicine is penetrated into the first oven 3 for the first drying; to prevent air bubbles between the liquid medicine and the gelling agent;

[0088] S1.4 After drying, the wire core enters the viscose equipment and wraps a layer of gelling agent on its outer surface;

[0089] After the S1.5 wire core is wrapped with a layer of gelling agent,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com