Plastic runway primer paving equipment

A technology of plastic runway and primer, applied in the field of plastics, can solve the problems of poor laying effect, poor laying effect, and affecting laying effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

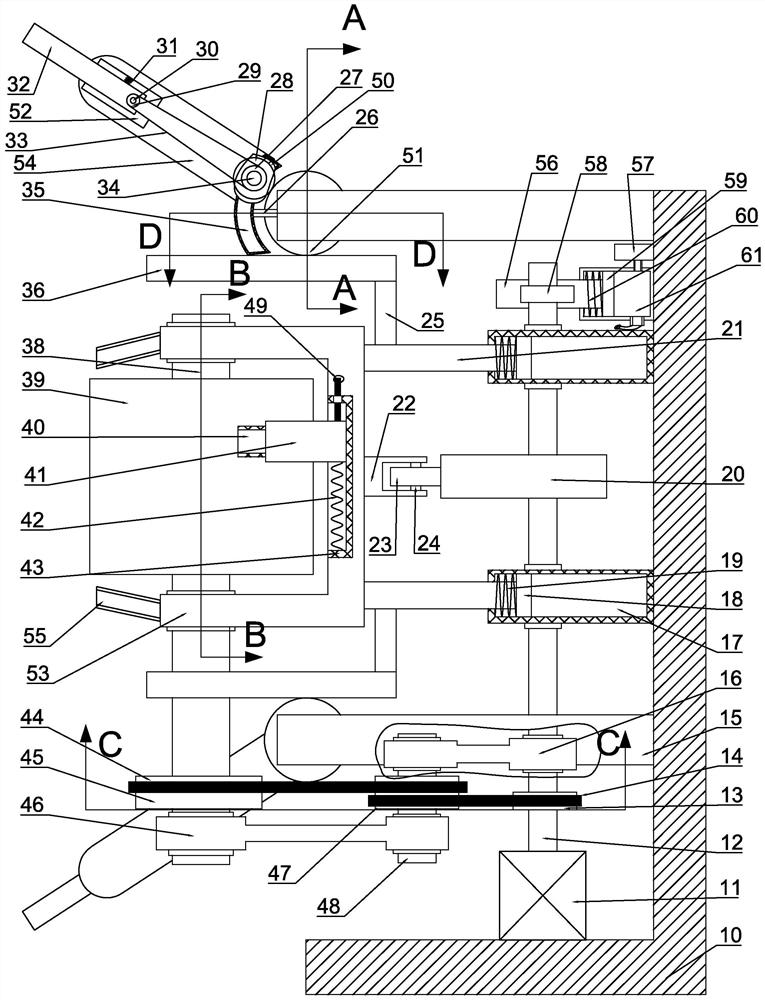

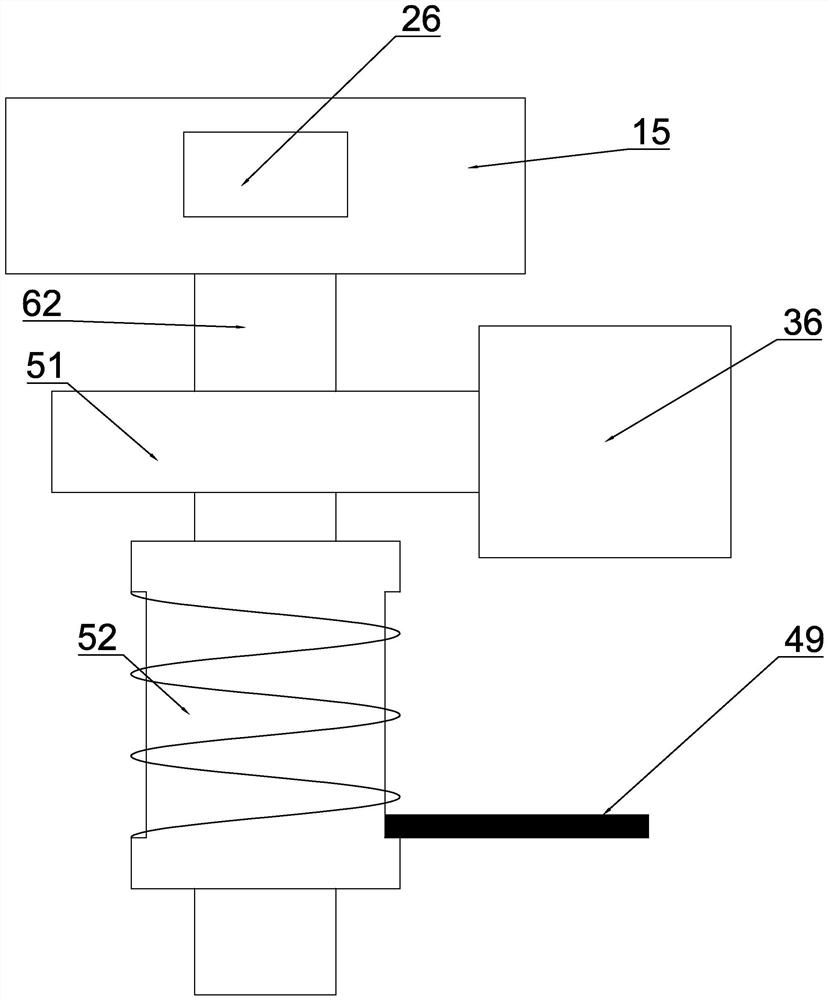

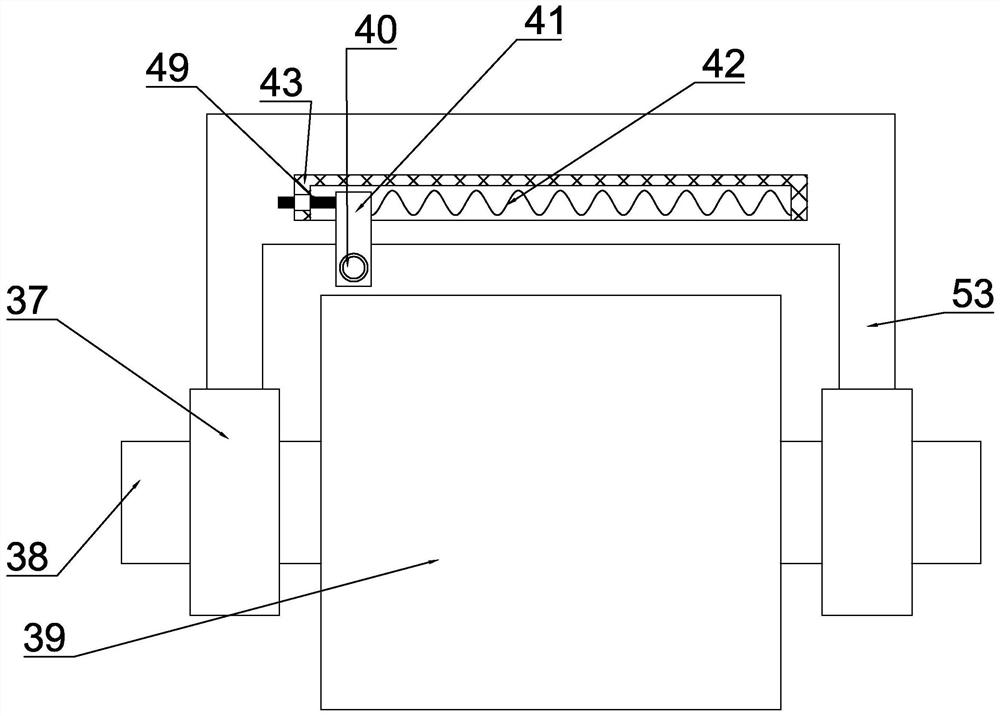

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0022] Such as figure 1 As shown, a plastic runway primer laying equipment includes a housing 10, two vertically symmetrical fixed cavities 17 are fixed on the side wall of the housing 10, and a fixed cavity slider 18 is slid in the fixed cavity 17. A slide block spring 19 is connected between the fixed cavity slider 18 and the left side wall of the fixed cavity 17, the left end of the fixed cavity slide block 18 is fixedly provided with a moving bar 21, and a push block 53 is fixedly arranged between the upper and lower two moving bars 21. The left end of the block 53 is fixedly provided with a paint spray port 55, and the push block 53 is provided with a push coating device, which is used to push the primer onto the asph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com