Automatic conveying and sorting workbench based on photoelectric sensing judging classification

A technology of automatic conveying and photoelectric sensing, applied in the field of electrical equipment, can solve the problems of wasting labor costs, wasting time costs, occupying labor force, etc., to achieve the effect of liberating labor and labor costs, improving sorting efficiency, and reducing time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

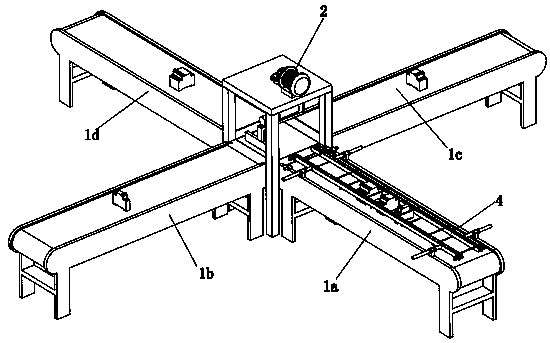

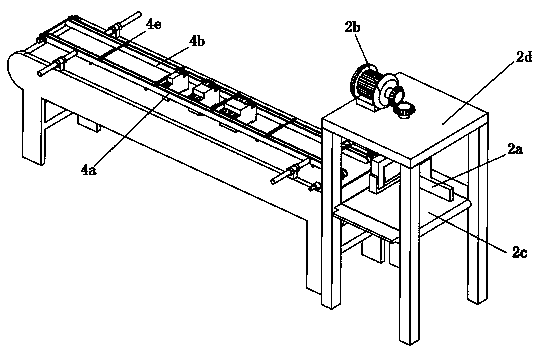

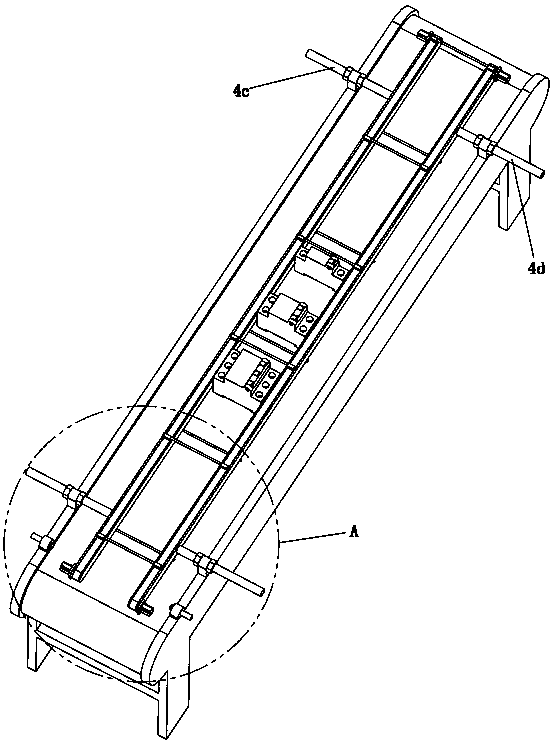

[0020] refer to Figure 1 to Figure 5 The shown automatic conveying and sorting workbench based on photoelectric sensor judgment and classification includes a sorting device 2 for sorting miniature circuit breakers, a detection device for detecting types of miniature circuit breakers, and a detection device for transporting miniature circuit breakers. The transmission device and the control device, the transmission device includes several conveyor belts distributed around the sorting device 2, and the detection device includes a through-beam photoelectric sensor 3 arranged at one end of one of the conveyor belts close to the sorting device 2 , the sorting device 2 includes a push assembly 2a for pushing the sorted miniature circuit breakers to the corresponding conveyor belt and a drive assembly 2b for driving the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com