Tension influence coefficient analysis method improving freedom degree rolling stability

A technology of influence coefficient and analysis method, applied in the direction of tension/pressure control, etc., can solve the problems that the tension adjustment cannot give clear guidance, and the relationship between tension and rolling force is not introduced in detail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

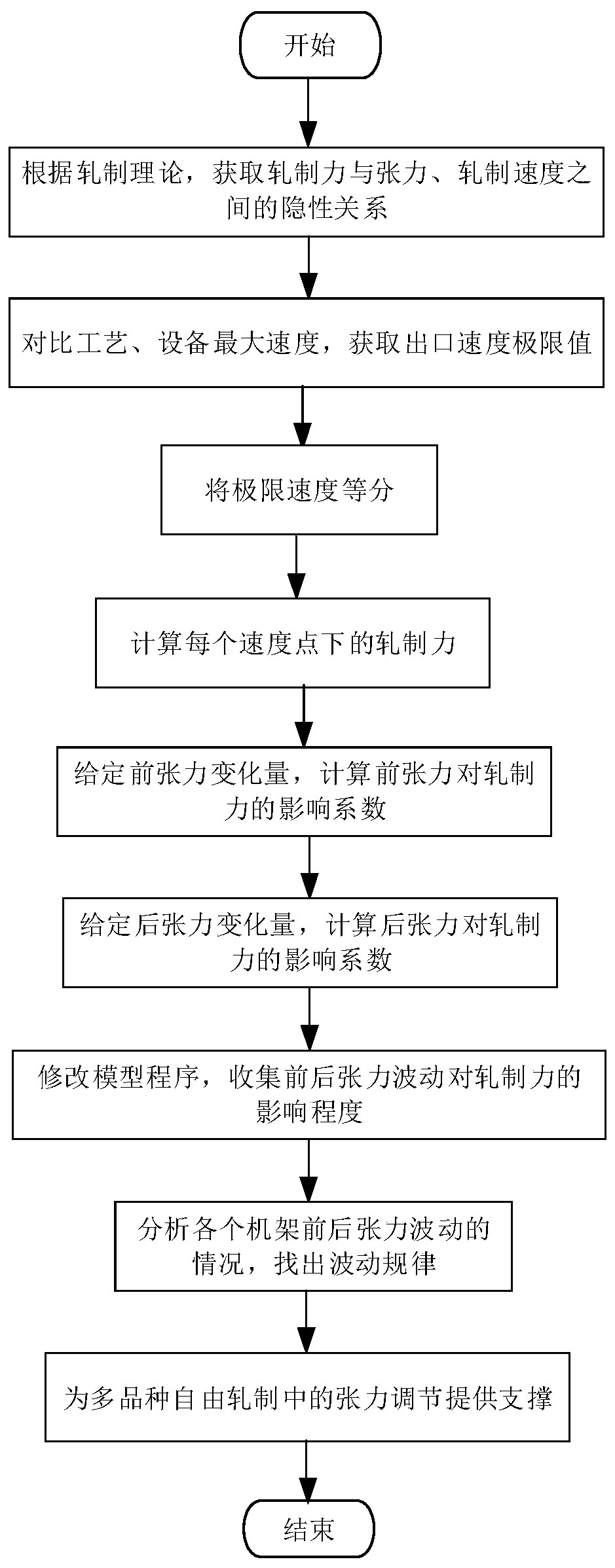

[0049] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

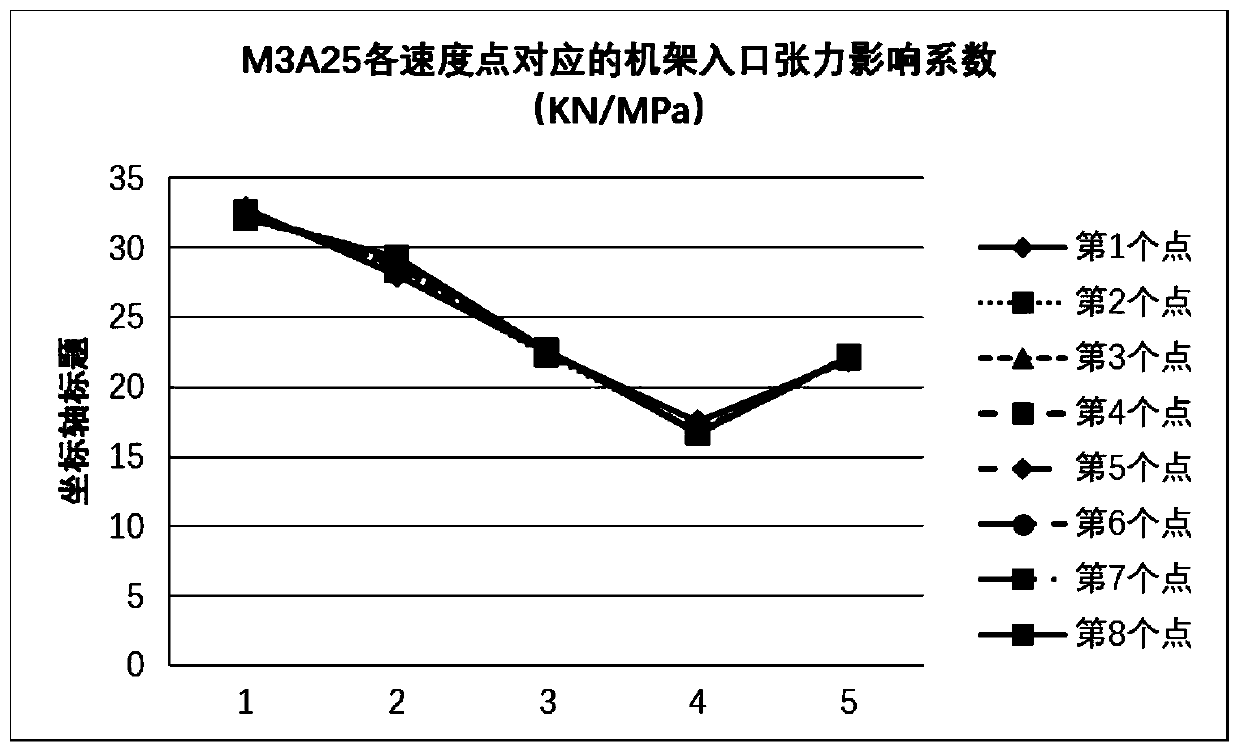

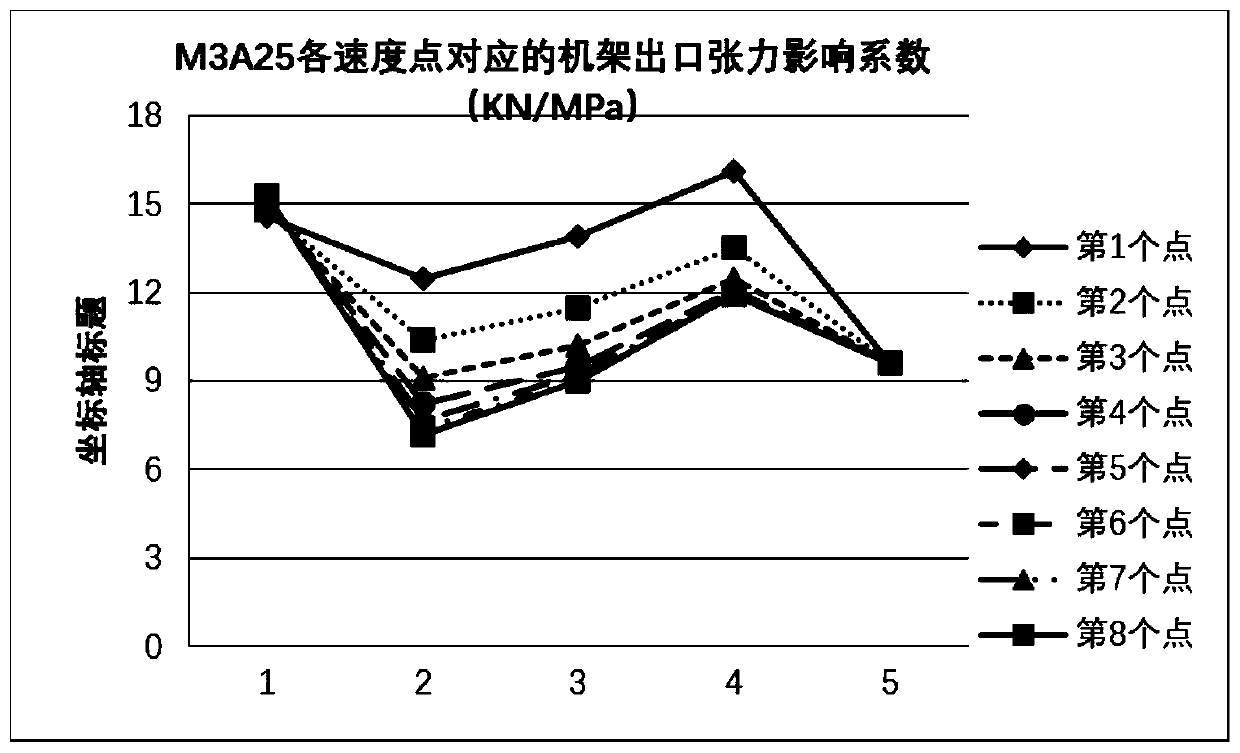

[0050] The present invention provides an analysis method of tension influence coefficient for improving the rolling stability of degree of freedom. When the production line changes varieties and specifications, the rolling force and the rolling force corresponding to each segmentation point are calculated by segmenting the speed. The influence coefficient of tension quantifies the influence of the tension of each stand on the rolling force, and statistically analyzes the distribution of the influencing factors in each stand, and gives suggestions for tension adjustment to provide strong support for stable rolling.

[0051] Such as figure 1 As shown, the method includes the following steps:

[0052] Including the following steps:

[0053] (1) Using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com