A Tensile Stress Dynamic Compensation Method for Improving the Stability of Rolling Process

A rolling process, dynamic compensation technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as strip instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

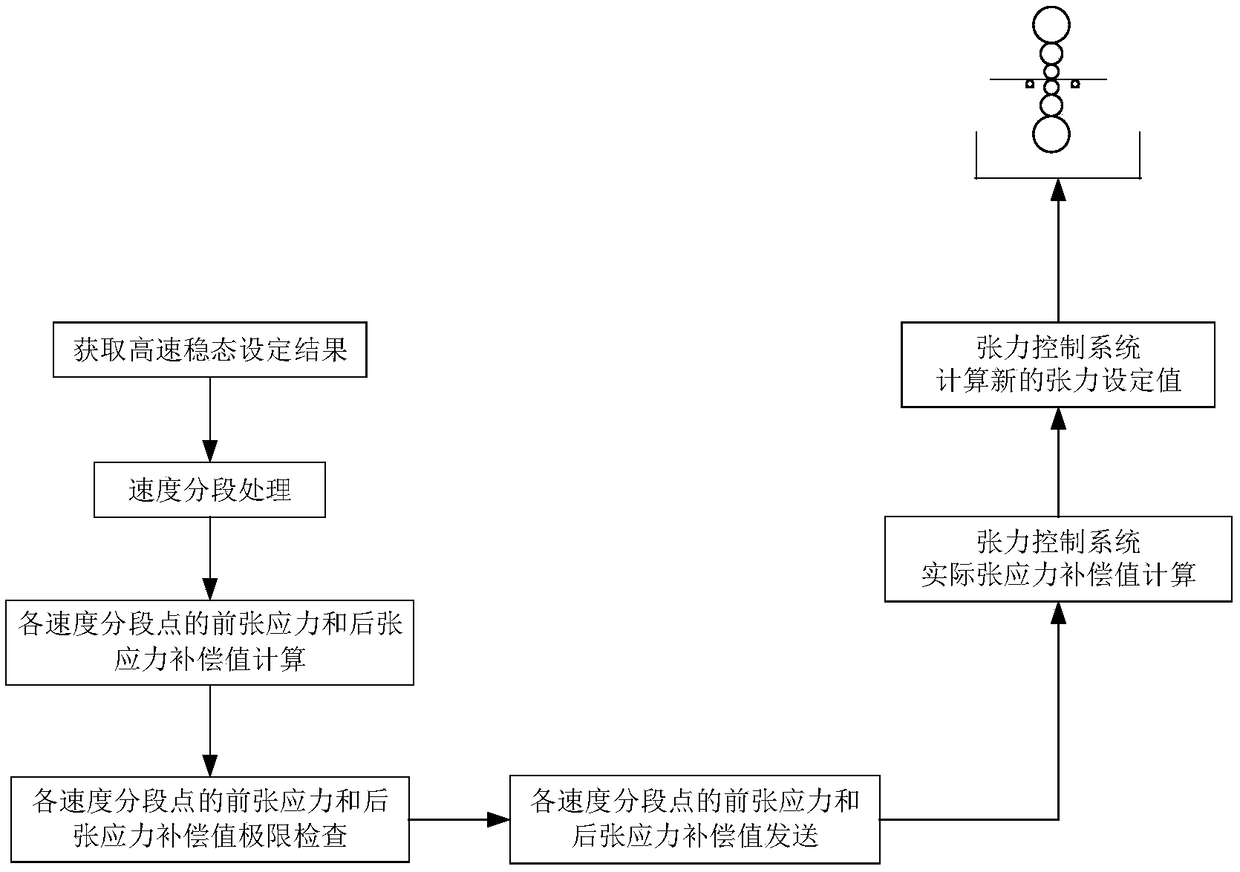

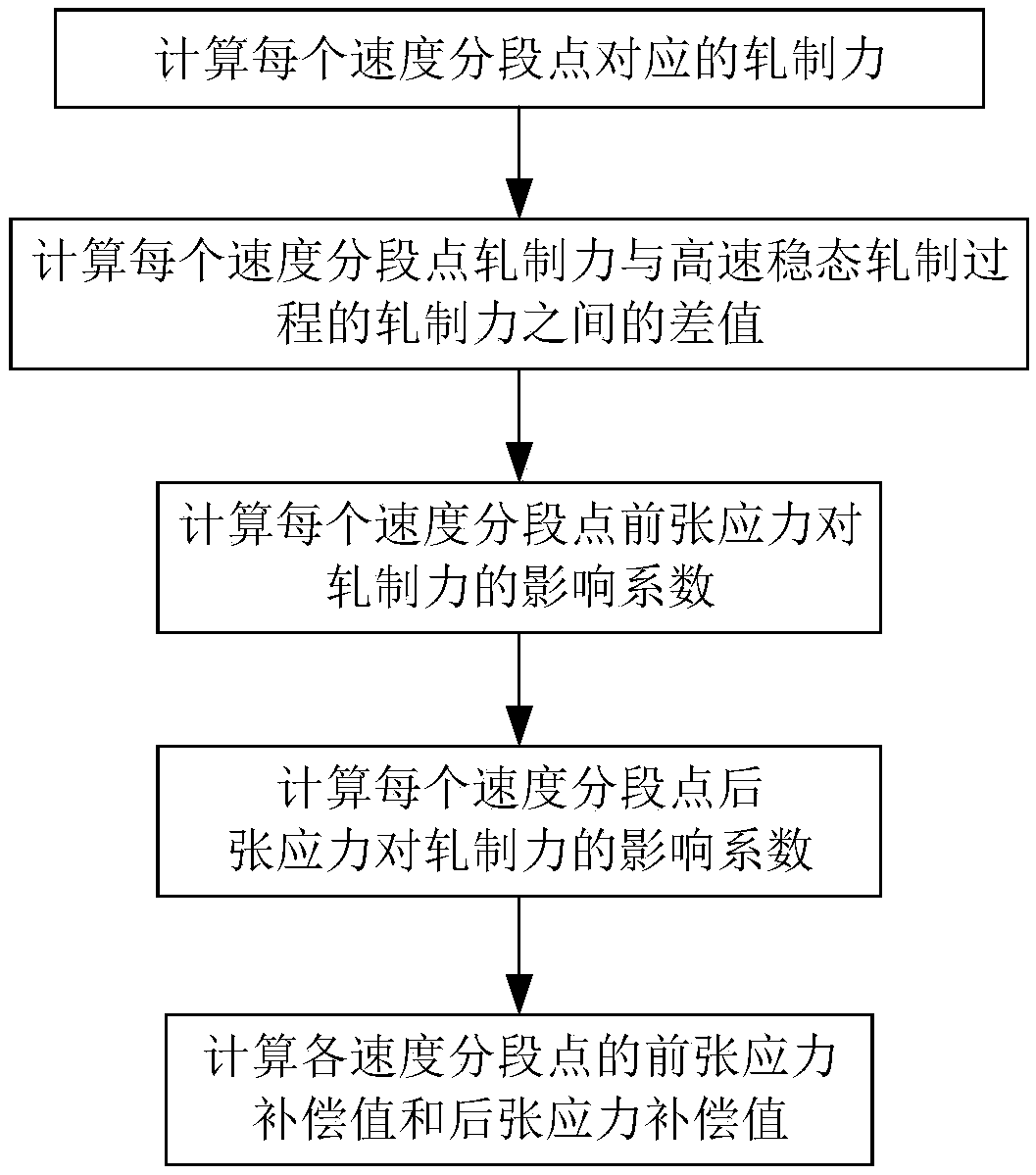

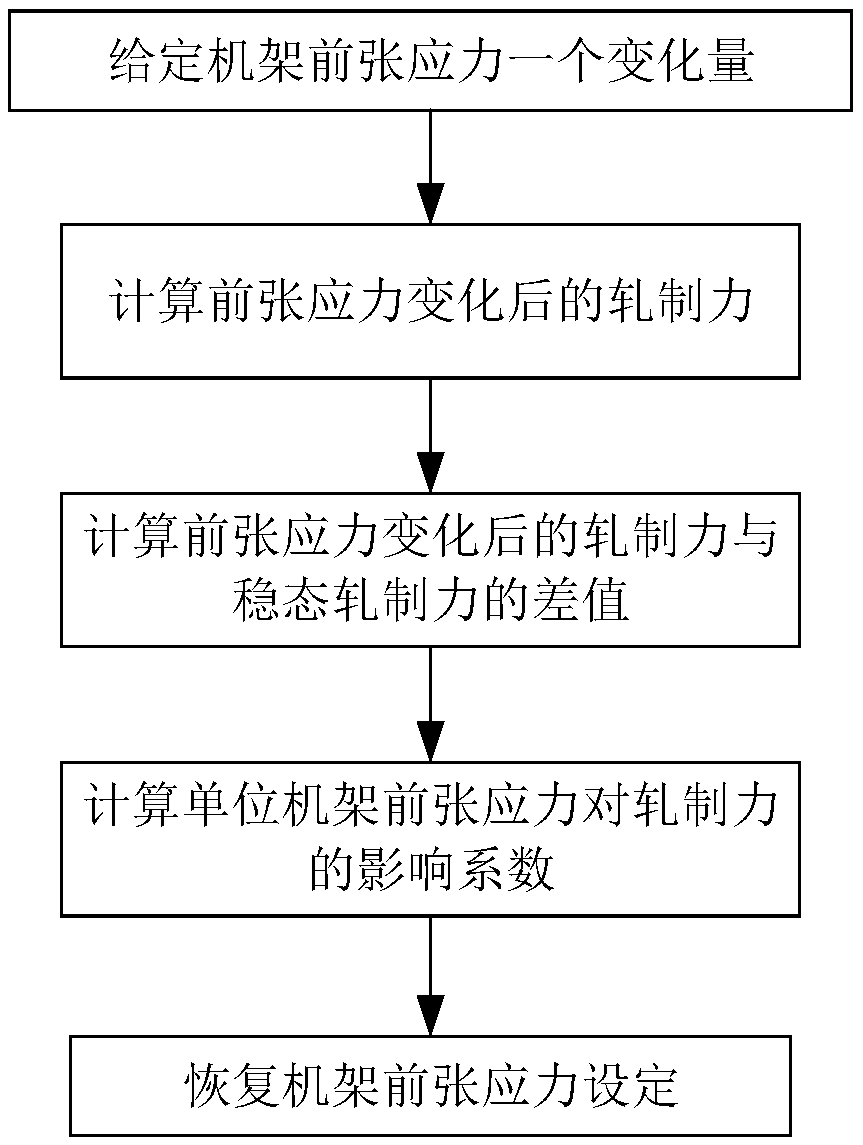

[0066] The invention proposes a method for dynamic compensation of tensile stress for improving the stability of rolling process. On the premise that the entire rolling speed range is segmented, the compensation values of the pre-tension stress and post-tension stress of the stand at each speed segment point are calculated, The tension control system calculates the actual required tensile stress compensation value according to the actual rolling speed, and calculates a new tension setting value for tension control to ensure the stability of the rolling process, and is applied to the cold rolling process. Examples are detailed as follows:

[0067] Taking the second stand of a specific tandem cold rolling production line as an example, the whole process of applying a dynamic compensation method for tensile stress to improve the stability of the rolling process will be described in detail below.

[0068] The main parameters of the cold tandem rolling line selected in this examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com