Multi-freedom-degree hole making device

A hole-making device and a technology with a degree of freedom, which can be used in feeding devices, manufacturing tools, large fixed members, etc., can solve complex surface hole-making problems, and achieve the effect of independent control and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings.

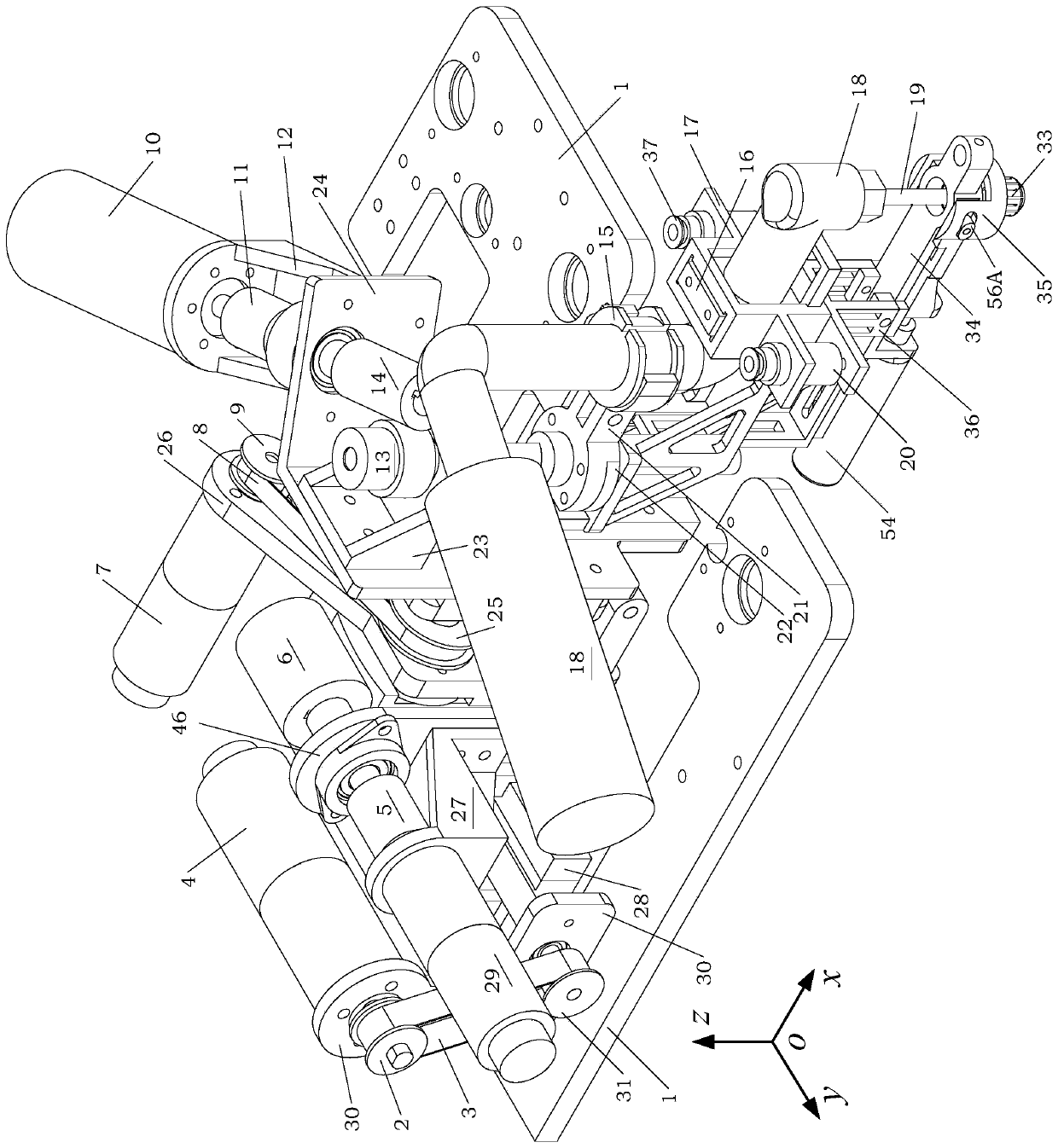

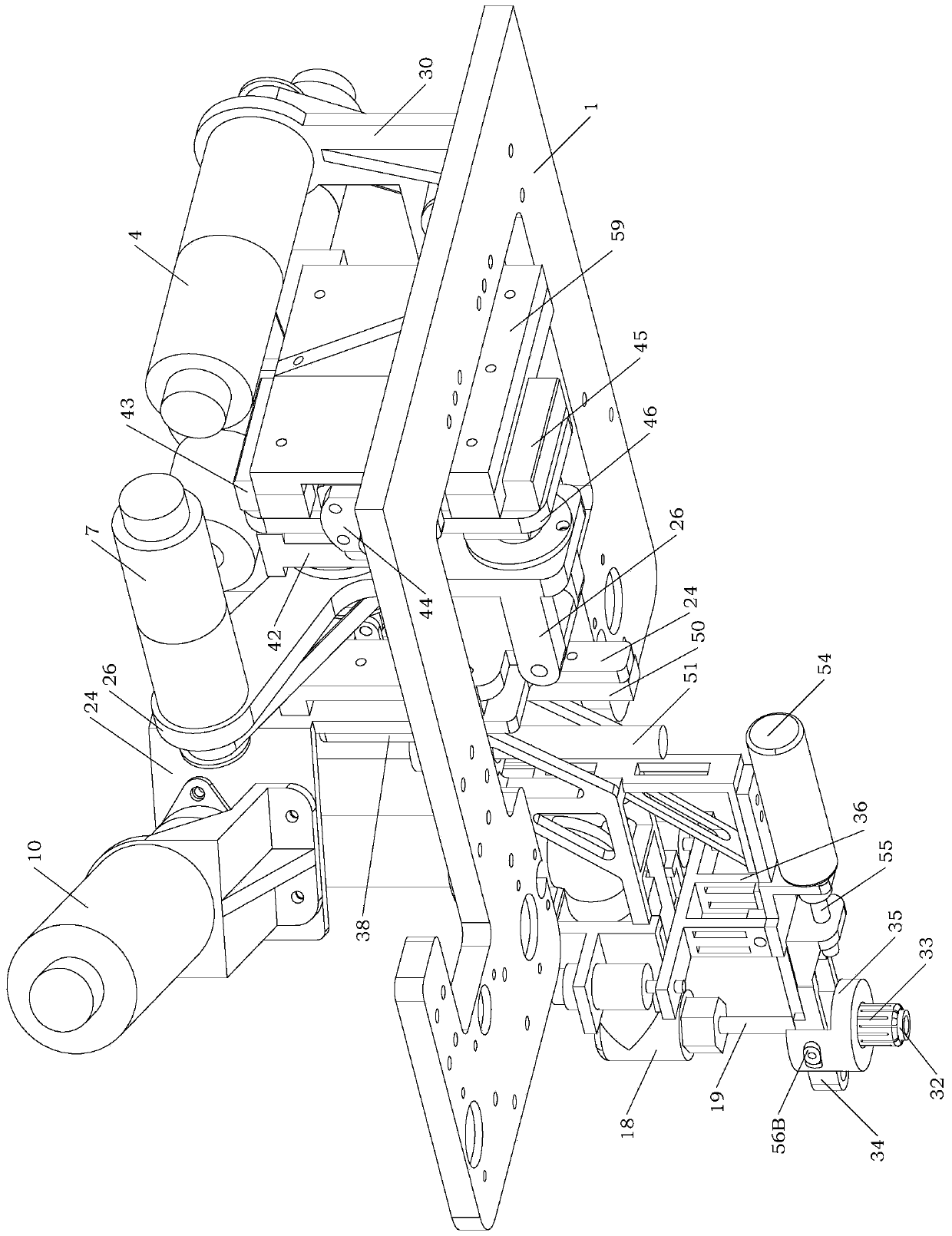

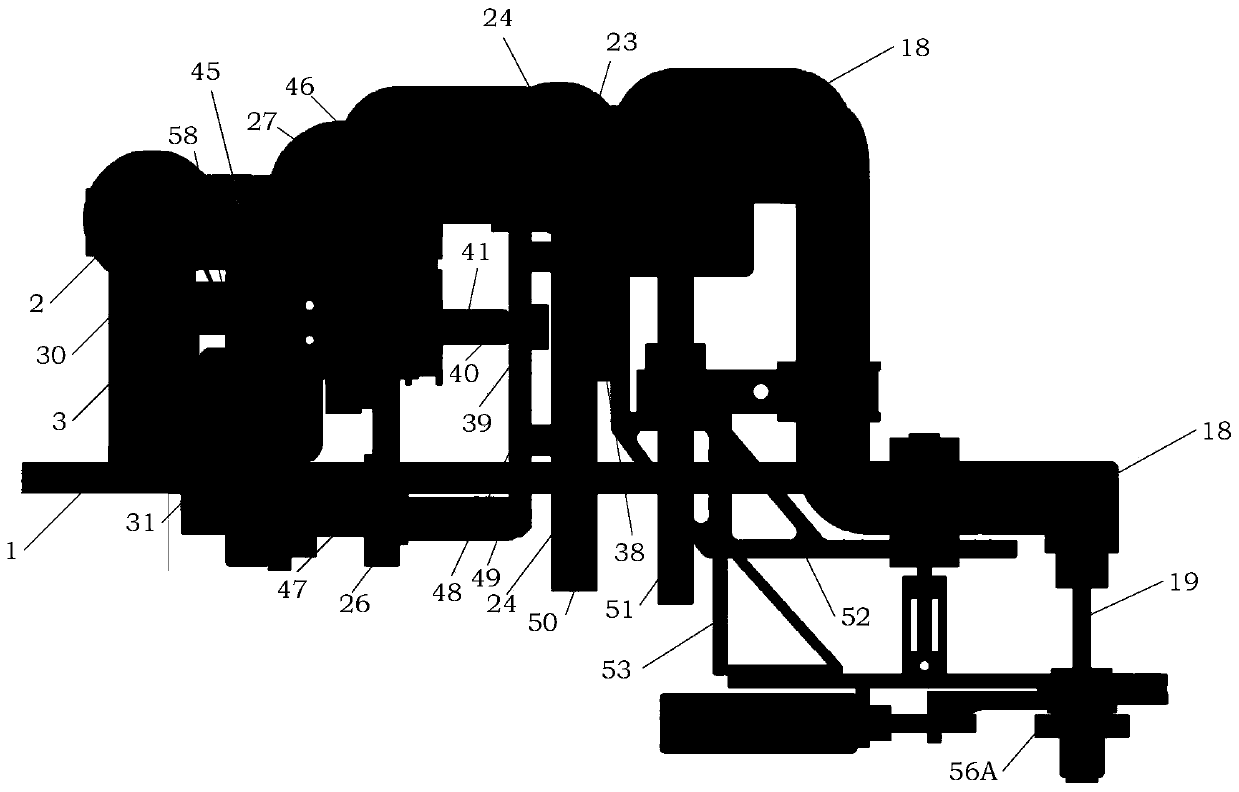

[0050] see figure 1 , Figure 1A , Figure 1B , Figure 1C , Figure 1D , Figure 1E As shown, the present invention designs a multi-degree-of-freedom hole-making device, which is suitable for processing holes in complex surfaces, narrow spaces, and processing blind areas. The multi-degree-of-freedom hole-making device of the present invention is divided into a support part, a pose adjustment part and a hole-making execution part. In the present invention, the RX axis represents an axis that can rotate around the X-axis direction, and the RY axis represents an axis that can rotate around the Y-axis direction.

[0051] (1) Support part

[0052] see figure 1 , Figure 1A , Figure 1B , Figure 1C , Figure 1D , Figure 1E , figure 2 , Figure 2A , Figure 2B As shown, the rear end panel 1A of the bottom plate 1 of the supporting part is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com