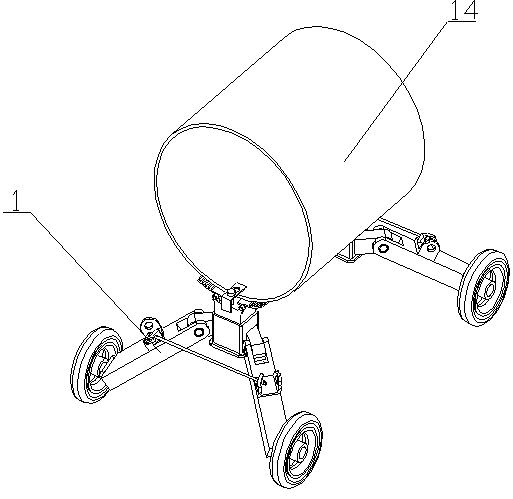

Large-caliber pipe fitting translation device

A translation device and large-diameter technology, which is applied in trolley accessories, transportation and packaging, multi-axis trolleys, etc., can solve problems such as increased construction costs, complicated conditions, and inability to adapt to pipeline translation, so as to reduce impact and reduce floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

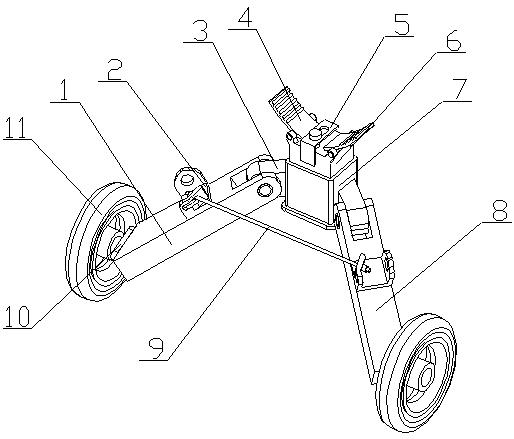

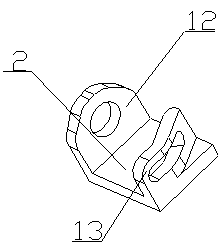

[0020] A large-diameter pipe fitting translation device of the present invention is realized in this way. It consists of a main support arm (1), an adjusting plate (2), a hinged frame (3), an arc-shaped supporting plate (4), a pressing plate (5), and a piston rod ( 6), buffer cylinder liner (7), auxiliary support arm (8), adjustment rod (9), fixed plate (10), moving wheel (11), ring plate (12) and adjustment limit plate (13), There are hinged frames (3) on the two opposite outer walls of the buffer cylinder liner (7). One end of the frame is hinged on a hinged frame (3), the middle of the main support frame is fixed with an adjustment plate (2), and the moving wheel (11) is installed on the other end of the main support frame through the fixed plate (10). One end of the supporting frame is hinged on another hinged frame (3), an adjusting plate (2) is fixed in the middle of the auxiliary supporting frame, and the moving wheel (11) is installed on the other end of the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com