Single-wall corrugated pipe serving as hollow reinforcing rib of structural wall pipe

A technology for structural wall pipes and single-wall corrugated pipes, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problem of reducing the bending strength of pipes, poor ring stiffness of circular single-wall corrugated pipes, weak connections, etc. Problems, to achieve the effect of improving the overall bending strength, firm and stable structure, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

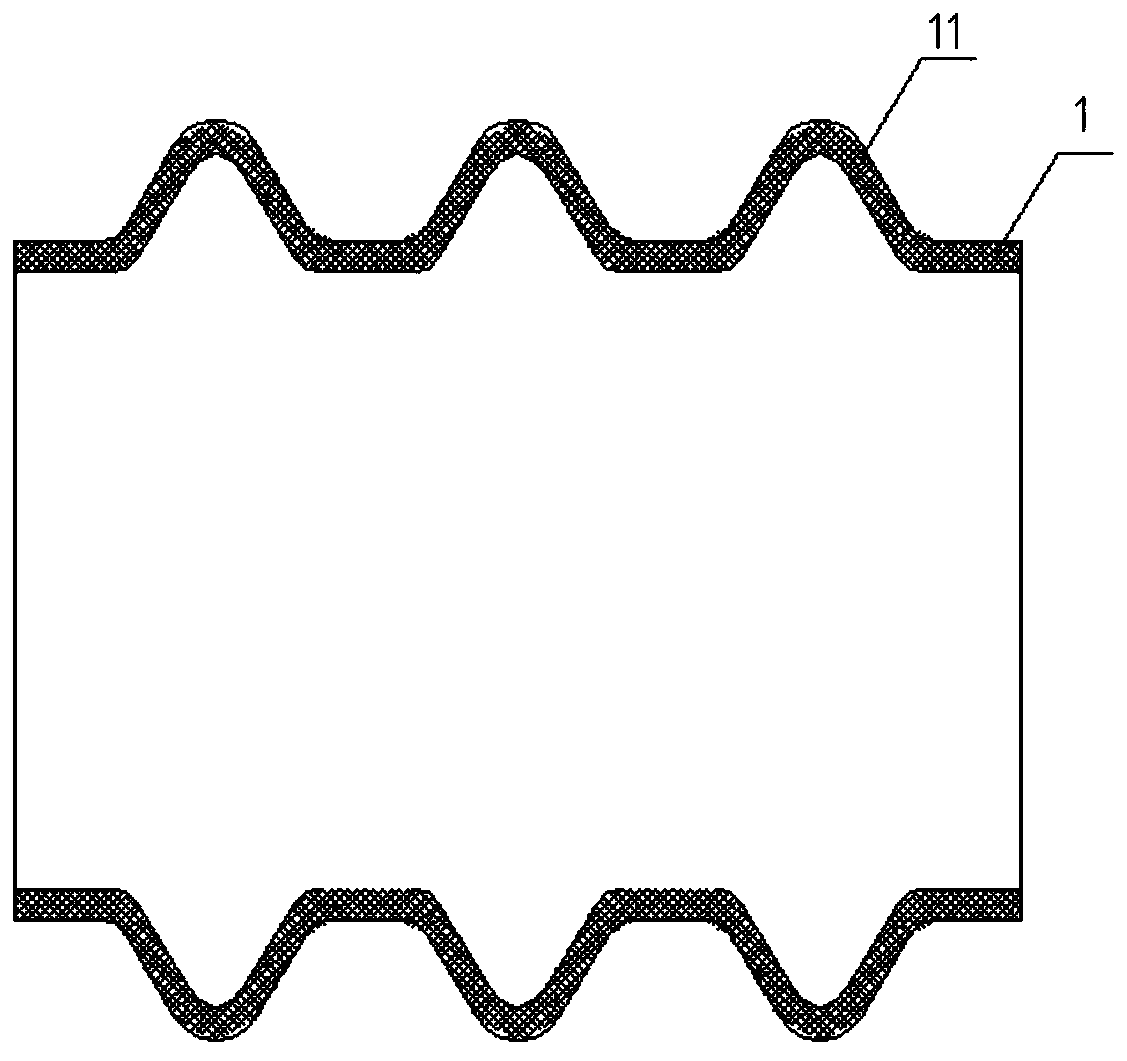

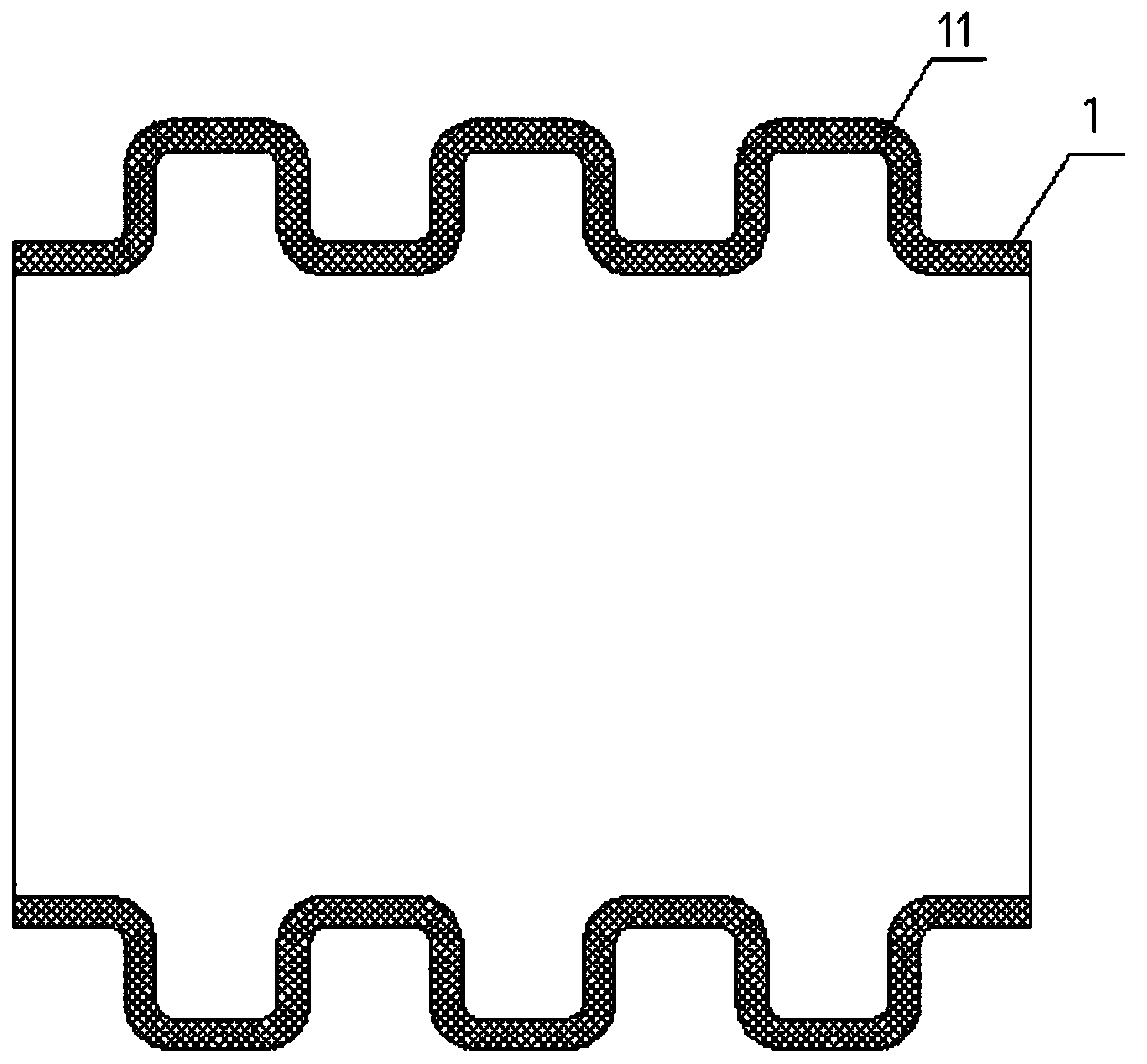

[0020] Example 1: as Figure 1 to Figure 5 As shown in the figure, a single-wall corrugated pipe as a hollow reinforcing rib of a structural wall pipe material in this embodiment includes a pipe body 1, and a plurality of corrugated protrusions 11 arranged at uniform intervals are formed on the pipe body 1. The corrugated protrusions The cross section of the starting 11 is circular, elliptical or polygonal. The pipe body is made by one-time molding.

[0021] Preferably, the corrugated protrusions 11 protrude toward the inner side wall of the pipe body 1 .

[0022] Preferably, the corrugated protrusions 11 are foldable and expandable. The corrugated protrusions can ensure the flexible bending of the pipe body at a relatively large angle without internal stress.

[0023] Preferably, the cross section of the pipe body 1 is oval or polygonal.

[0024] Further, the pipe body 1 is made of a mixed material of PP, PE, EVA, PVC, ABS, plastic and glass fiber material.

[0025] Furt...

Embodiment 2

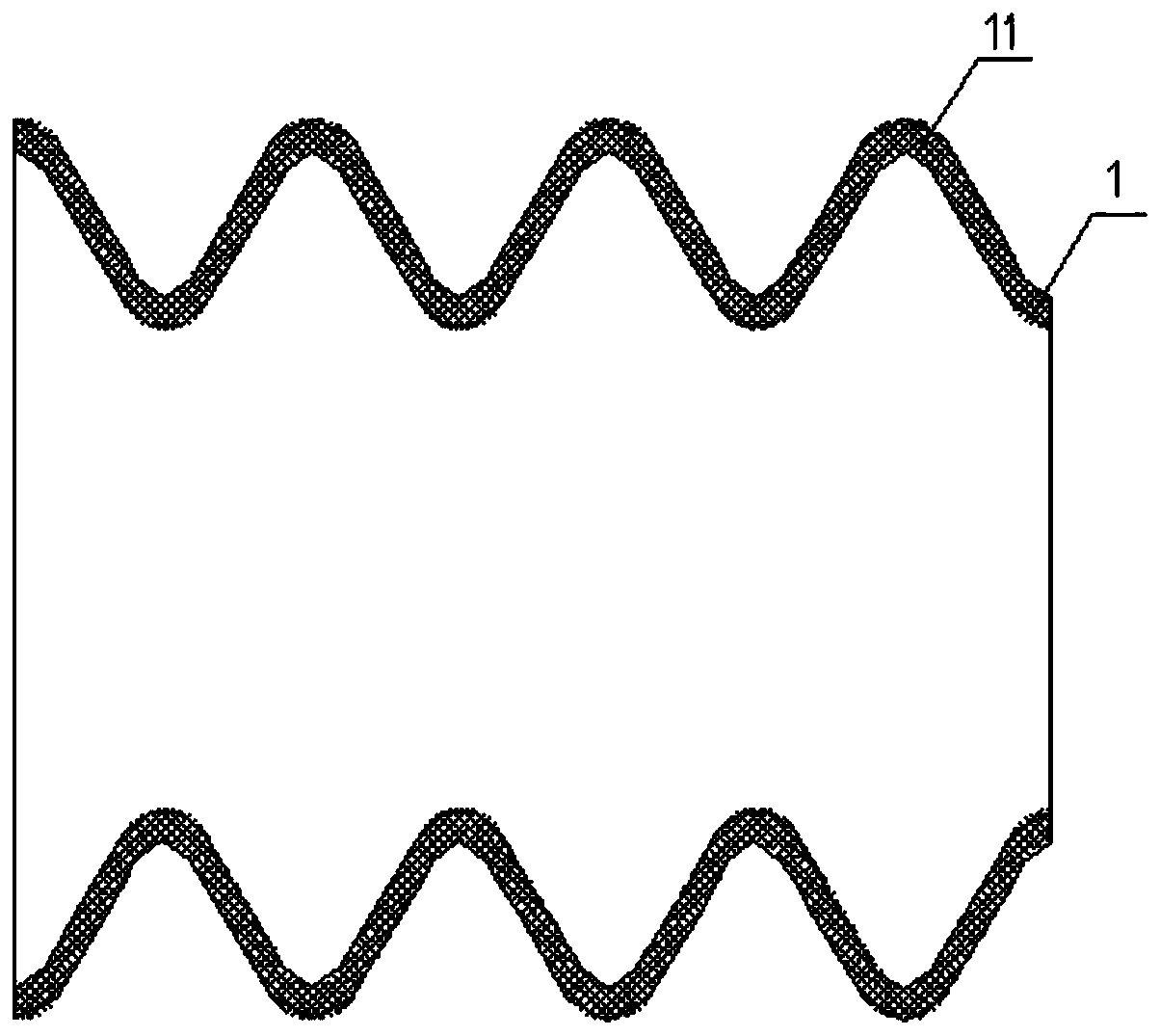

[0026] Example 2: as Figure 4 to Figure 6 As shown in the figure, a single-wall corrugated pipe as a hollow reinforcing rib of a structural wall pipe material in this embodiment includes a pipe body 1, and a plurality of corrugated protrusions 11 arranged at uniform intervals are formed on the pipe body 1. The corrugated protrusions The cross section of the starting 11 is circular, elliptical or polygonal. The pipe body is made by one-time molding.

[0027] Preferably, the corrugated protrusions 11 protrude toward the outer side wall of the pipe body 1 .

[0028] Preferably, the corrugated protrusions 11 are foldable and expandable. The corrugated protrusions can ensure the flexible bending of the pipe body at a relatively large angle without internal stress.

[0029] Preferably, the cross section of the pipe body 1 is oval or polygonal.

[0030] Further, the pipe body 1 is made of a mixed material of PP, PE, EVA, PVC, ABS, plastic and glass fiber material.

[0031] Furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com