OCX control-based intermittent kiln sintering process setting system and method

An intermittent, process technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of human error-prone operation, poor human-computer interaction experience, etc., to eliminate manual error operation, easy for operators Check, convenient effect of human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0026] The so-called OCX control in the embodiment of the present invention is: Object Linking and Embedding (OLE) ControlExtension, object linking and embedding user control (OCX) is a kind of special-purpose control that can be created and used by the application software that runs in Microsoft's Windows system program.

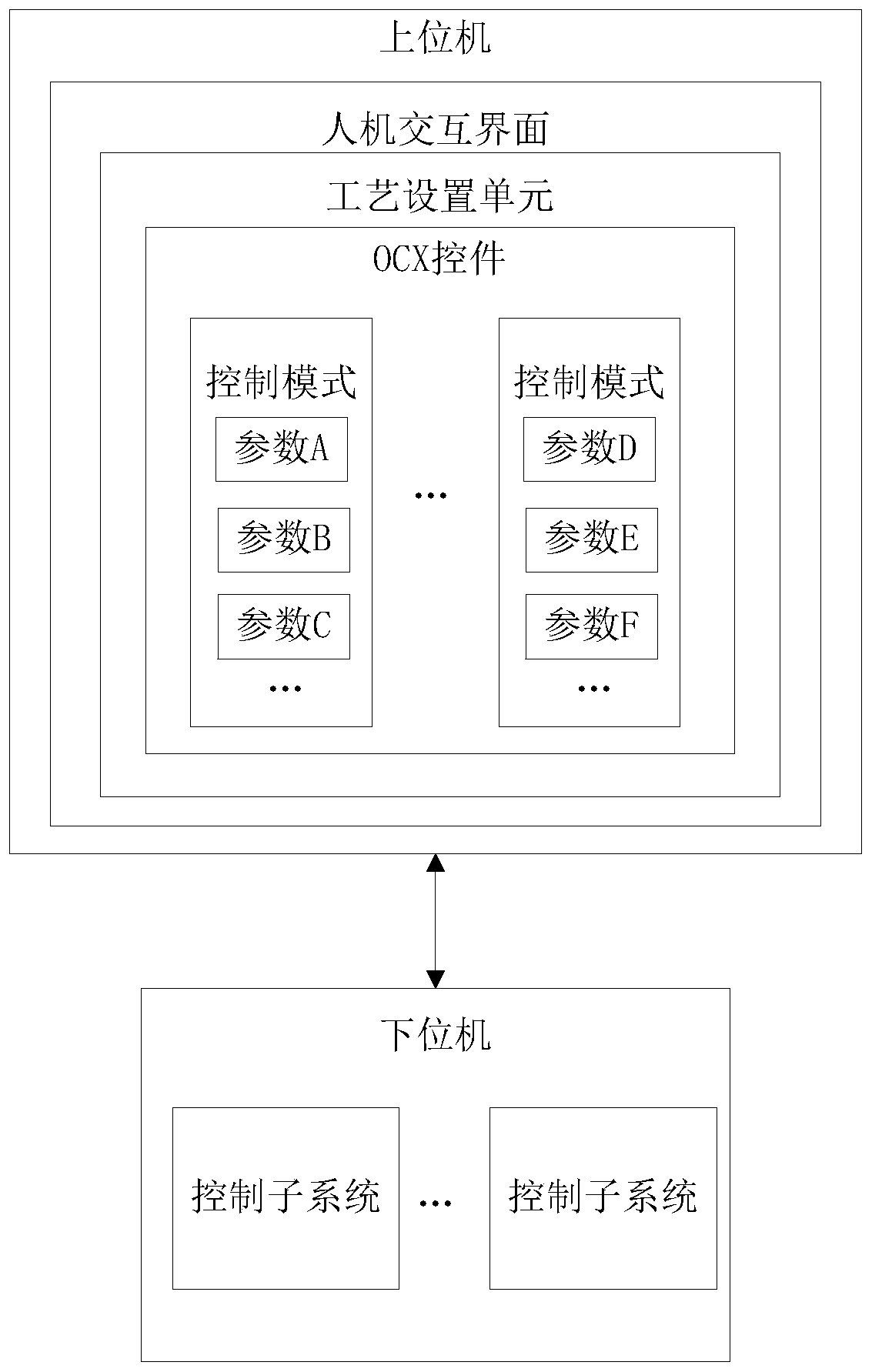

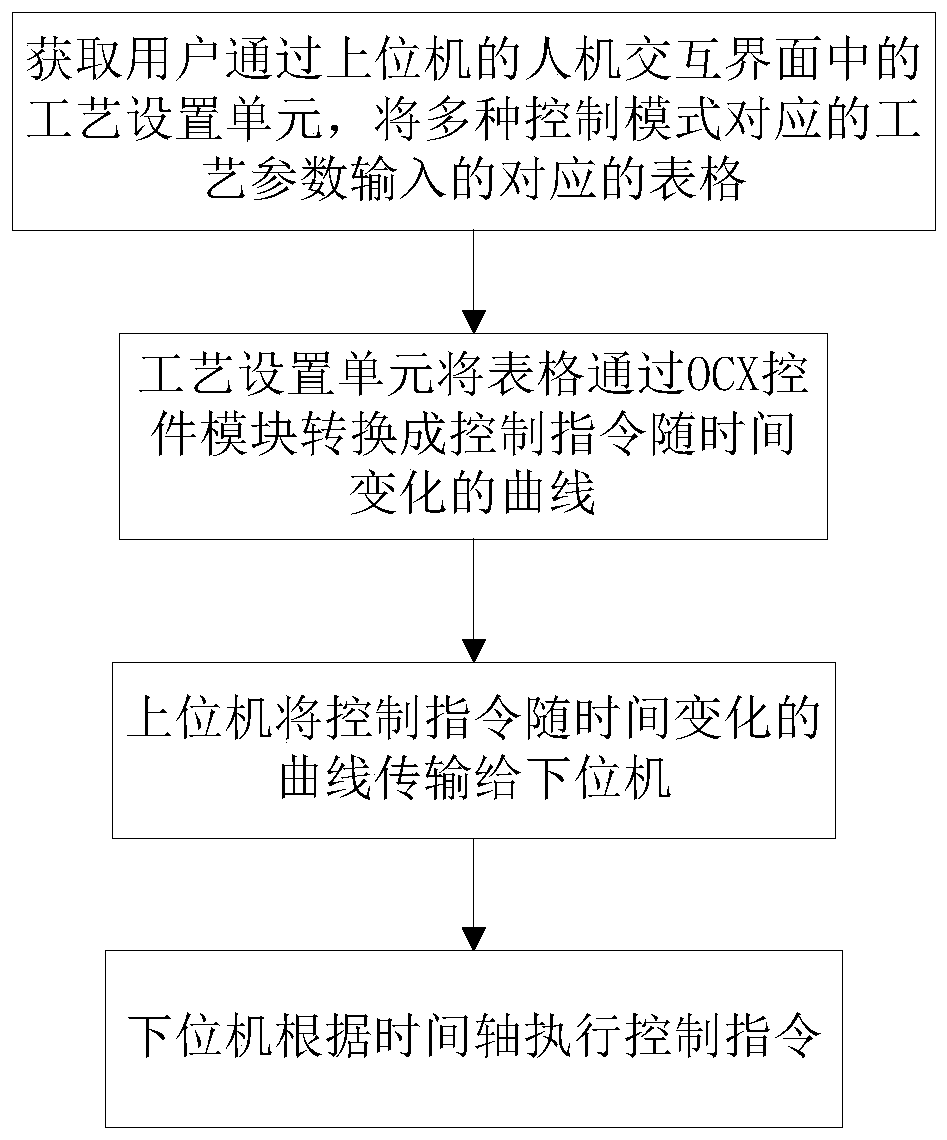

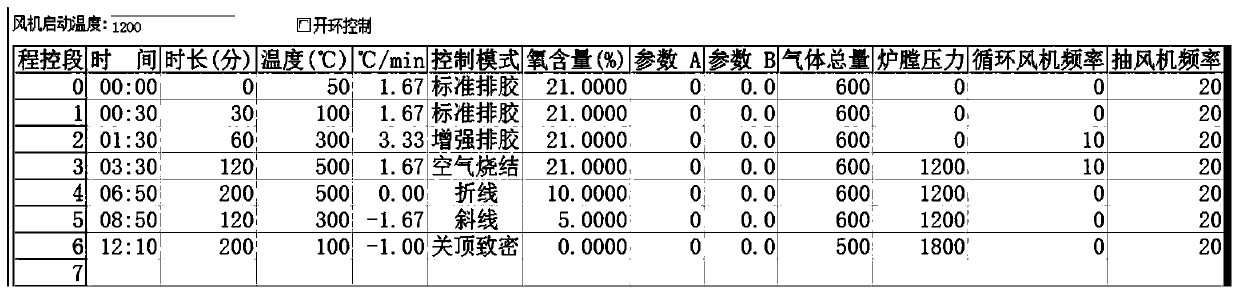

[0027] see figure 1 , the OCX control-based intermittent kiln sintering process setting system of the present invention includes a lower computer and a host computer with a human-computer interaction interface, the human-computer interaction interface includes a process setting unit, and an OCX control module is embedded in the process setting unit. The OCX control module includes various control modes in the sintering process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com