A transparent conductive film structure and a preparation method thereof

A transparent conductive film and metal wire technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve problems such as moiré, affecting the optical effect of the metal grid touch screen, etc., to achieve good optical effect, The effect of suppressing moiré

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

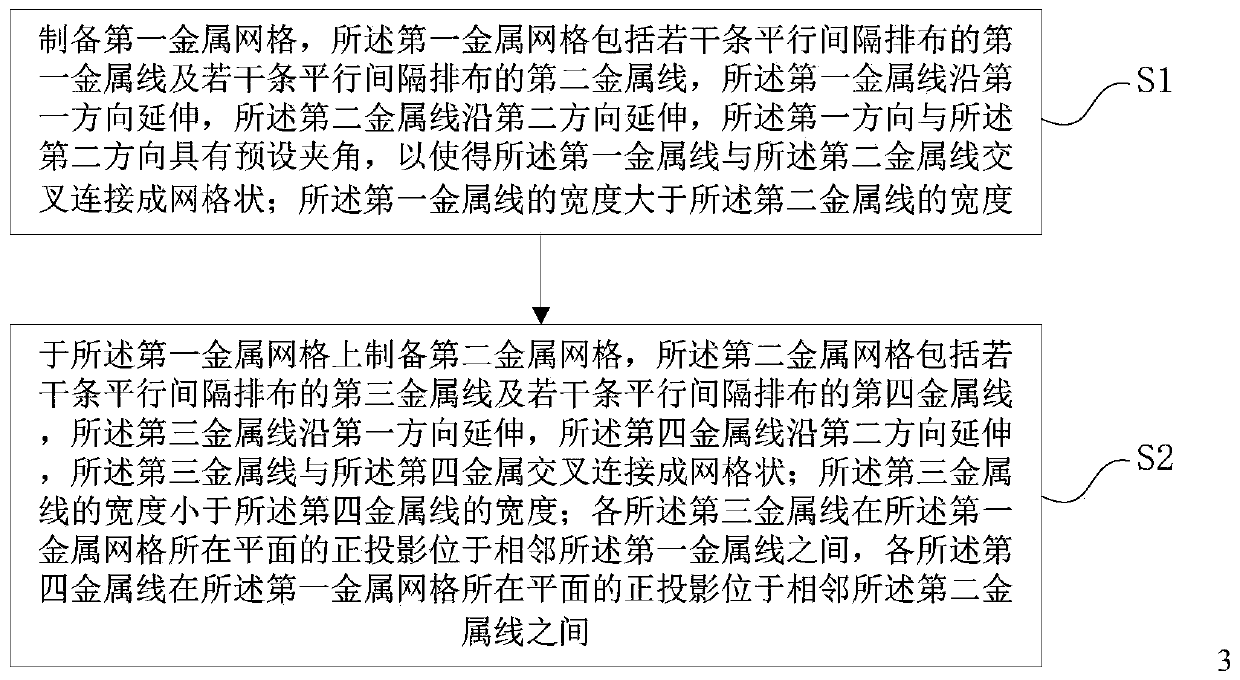

[0062] Please figure 1 , this embodiment provides a method for preparing a transparent conductive film structure, the method for preparing a transparent conductive film structure includes the steps of:

[0063] 1) Prepare a first metal grid, the first metal grid includes a plurality of first metal wires arranged in parallel at intervals and a plurality of second metal wires arranged in parallel at intervals, the first metal wires are arranged along the first direction, the second metal line extends along the second direction, the first direction and the second direction have a preset angle, so that the first metal line and the second metal line are cross-connected to form Grid shape; the width of the first metal line is greater than the width of the second metal line;

[0064] 2) preparing a second metal grid on the first metal grid, the second metal grid comprising a plurality of third metal wires arranged in parallel at intervals and a plurality of fourth metal wires arrang...

Embodiment 2

[0114] Please combine Figure 2 to Figure 18 , this embodiment also provides a transparent conductive film structure, the transparent conductive film structure includes: a first metal grid 13, the first metal grid 13 includes a plurality of first metal wires 131 arranged in parallel at intervals and A plurality of second metal wires 132 arranged in parallel at intervals, the first metal wire 131 extends along the first direction, the second metal wire 132 extends along the second direction, the first direction and the second direction There is a preset angle, so that the first metal line 131 and the second metal line 132 are cross-connected to form a grid; the width of the first metal line 131 is greater than the width of the second metal line 132; The second metal grid 16, the second metal grid 16 is located on the first metal grid 13, the second metal grid 16 includes a number of third metal wires 161 arranged in parallel and at intervals and a number of Fourth metal lines ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com