Intermittent blanking type powder making device for western medicine tablets

A pulverizing device and a blanking technology, which is applied in the directions of feeding and oral medicine utensils, etc., can solve the problems of waste of tablets, uneven feeding method, inability to grind tablets, etc., and achieve the effect of strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

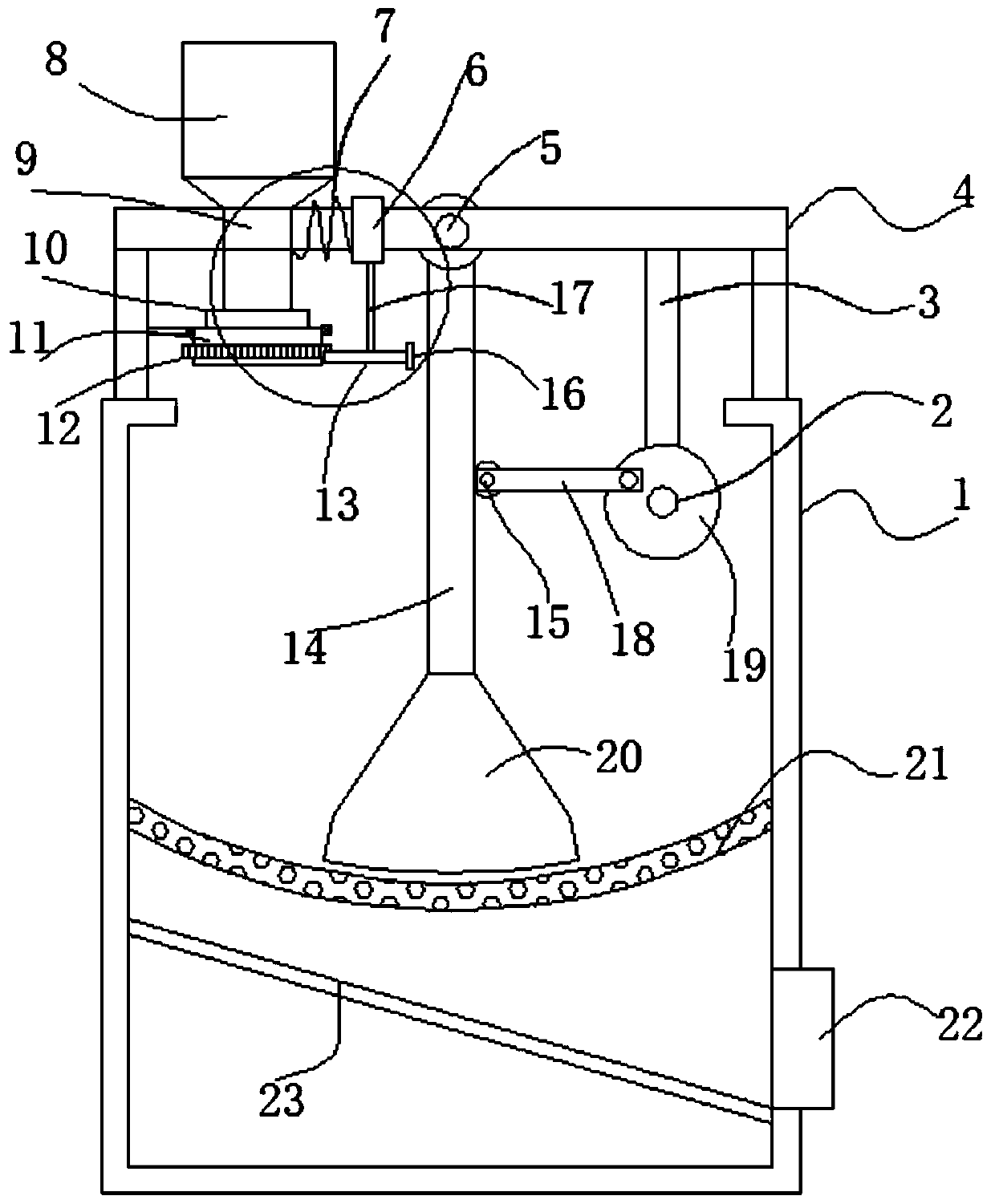

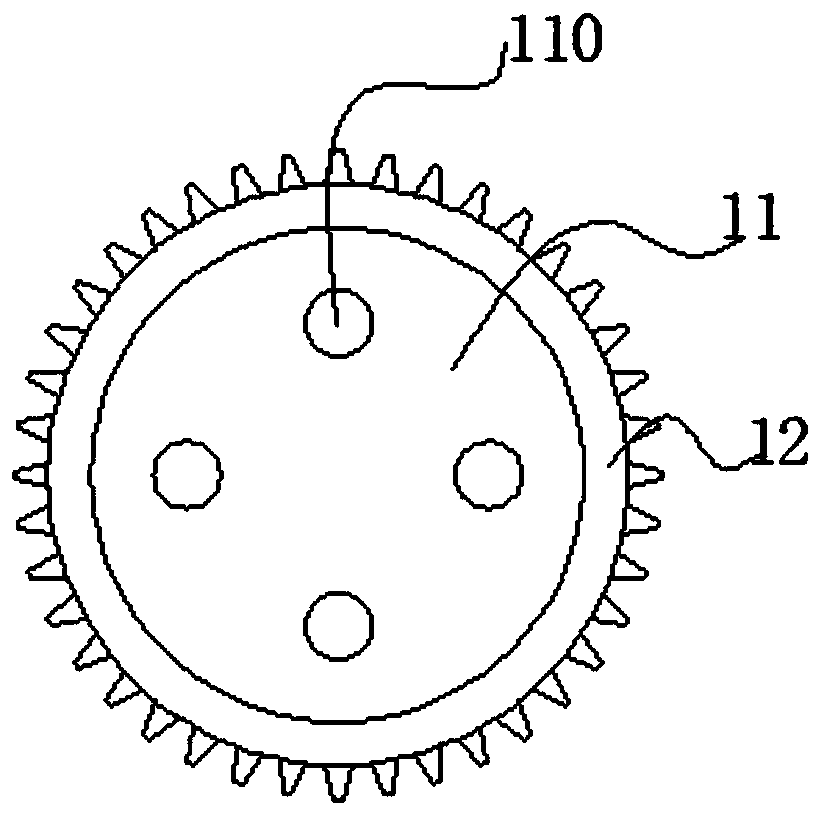

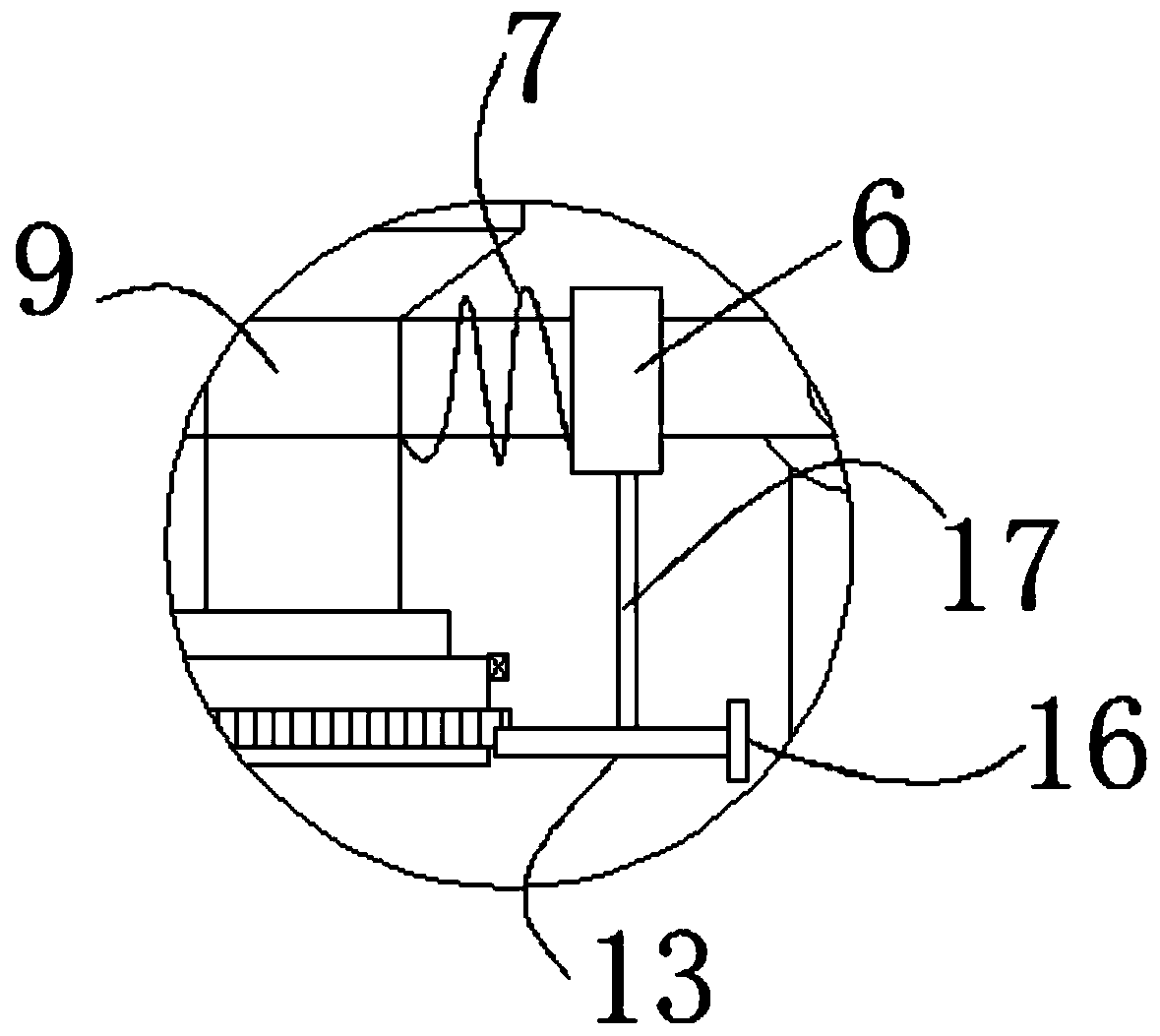

[0021] see Figure 1~3 , in an embodiment of the present invention, a western medicine tablet intermittent blanking type milling device comprises a box body 1, and the inner bottom of the box body 1 is provided with a material guide sloping plate 23 arranged high on the left and low on the right. The surface of the plate 23 is provided with a ceramic layer, the right end of the guide slant plate 23 is provided with a discharge port 22, the top of the box 1 is provided with a fixed frame 4, and the fixed frame 4 is connected with a suspension rod through a fixed rotating shaft 5. 14. The lower end of the suspender 14 is provided with a grinding block 20, and the inner bottom of the box 1 is provided with a grinding bottom plate 21 matching with the grinding block 20. Correspondingly, the surface of the grinding bottom plate 21 is evenly distributed with blanking holes, the fixed frame 4 is provided with a driving mechanism for driving the suspension rod 14 to swing left and rig...

Embodiment 2

[0027] The difference from Example 1 is: .

[0028] In order to avoid the impact of grinding heat on the medicinal properties of medicinal materials, a water storage chamber is provided inside the grinding block 20, and water is installed in the water storage chamber, and the heat generated by grinding is absorbed by the large specific heat capacity of water. Heat dissipation protrusions are provided to increase the heat dissipation area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com