Steering shuttle bus double-passage type track structure

A dual-channel, shuttle technology, applied in the field of logistics, can solve problems such as route conflicts, reduce storage efficiency, reduce overall storage volume, etc., and achieve the effect of increasing floor space and improving storage efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

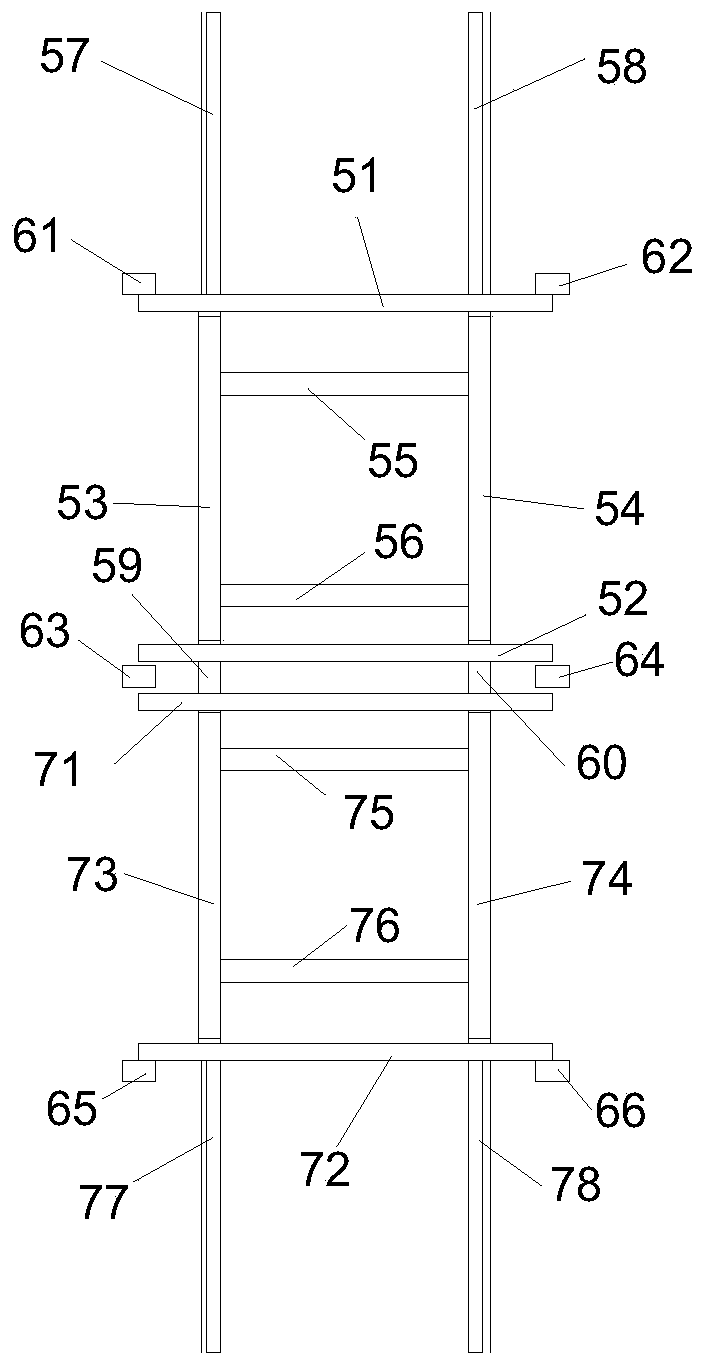

[0021] Such as figure 1 As shown, this embodiment provides a dual-channel track structure for a steering shuttle, which is composed of a plurality of dual-channel track units. The second track turning assembly, the connection assembly connecting the first track turning assembly and the second track turning assembly, the first track turning assembly and the second track turning assembly have the same structure, and both include two parallel transverse rails 51 , 52 (71, 72), two vertical rails 53, 54 (73, 74) arranged between two transverse rails 51, 52 (71, 72), the connecting assembly includes two parallel Connecting rails 59, 60, the two connecting rails 59, 60 are respectively connected to the vertical rails 53, 54 (73, 74) on both sides through the horizontal rail 52 (71), and the horizontal rail 51 (72) The outside is connected with shuttle rack storage track 57,58 (77,78).

[0022] The dual-channel track structure provided by the present invention can be used for multi...

Embodiment 2

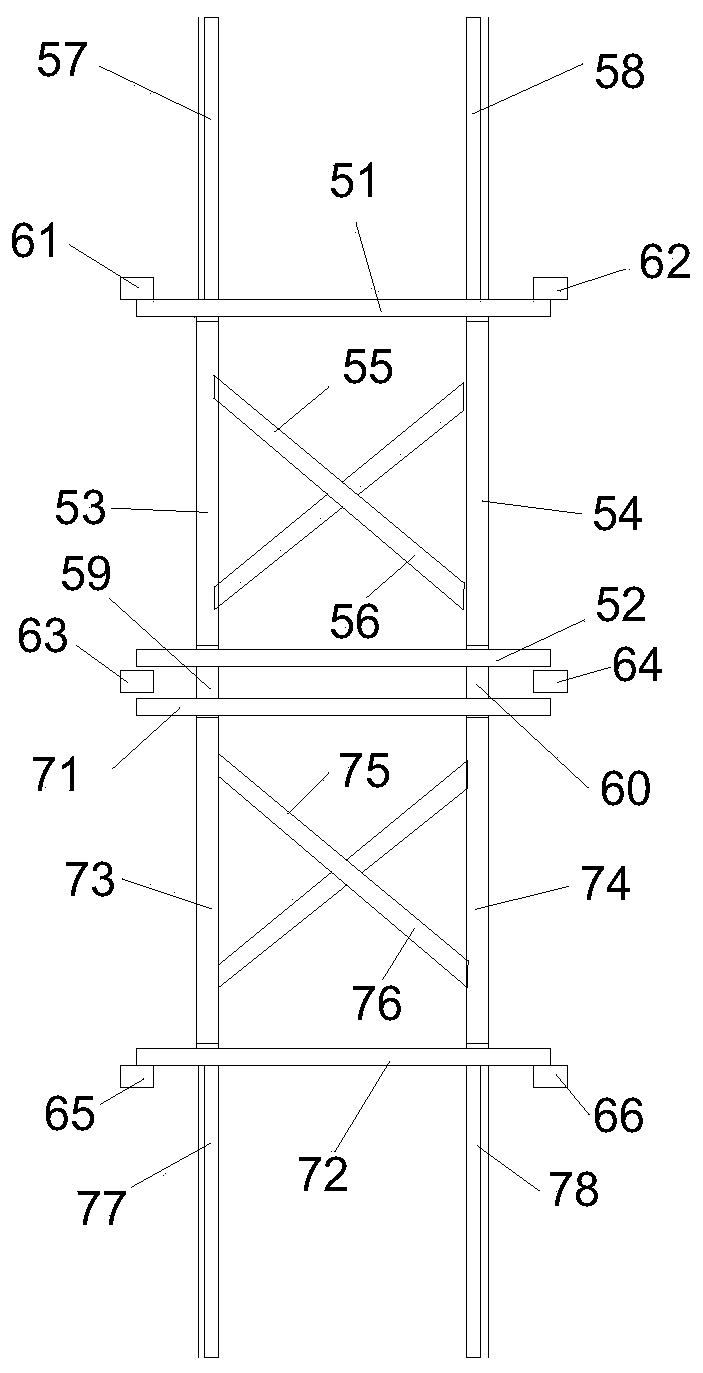

[0030] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is: the fixed reinforcing ribs 55, 56 (75, 76) are arranged in a cross, and the cross combination of fixed reinforcing ribs can strengthen the structural stability, and other structures are the same as in Embodiment 1. , which will not be repeated here.

Embodiment 3

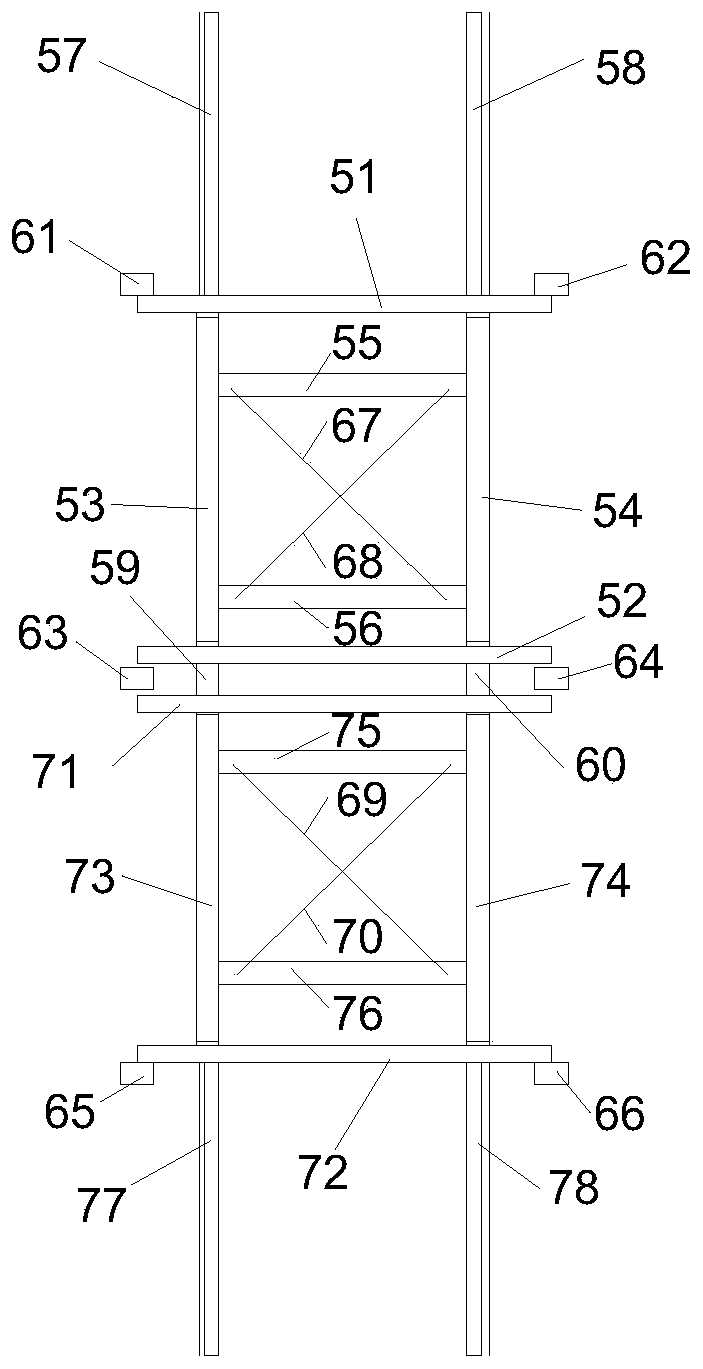

[0032] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the number of the fixed reinforcing ribs is four, and a cross fixing rib is also provided between the parallel fixed reinforcing ribs 55, 56 (75, 76). Ribs 67, 68 (69, 70) are in order to further strengthen the stability of the structure, and other structures are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com