Control method for producing trivalent chromium passivated steel coil

A control method, trivalent chromium technology, applied in the field of passivation, can solve problems such as improper use of parameters, reduction of personnel and equipment costs, technical effects, unstable control, etc., to solve improper use of parameters, and to facilitate long-term use and maintenance. The effect of reducing personnel and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] By providing a control method for producing trivalent chromium passivated steel coils, the embodiment of the present invention solves the technical problems of improper use of parameters and unstable control in the prior art, realizes the passivation quality of the product, and thus ensures that the strip steel The corrosion resistance and appearance quality of the surface are beneficial to the long-term use and maintenance of the equipment body, and the technical effect of reducing the cost of personnel and equipment.

[0035] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

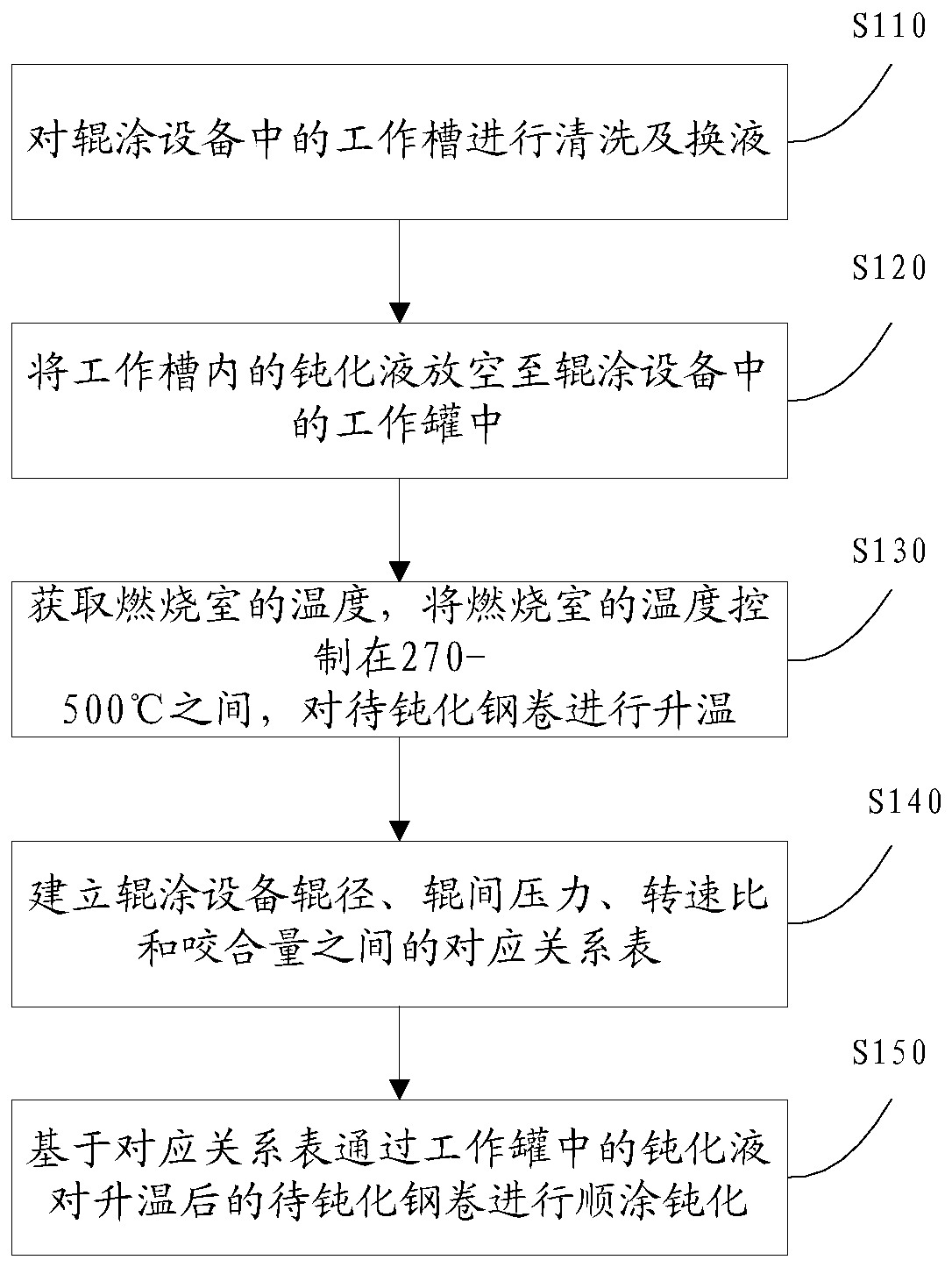

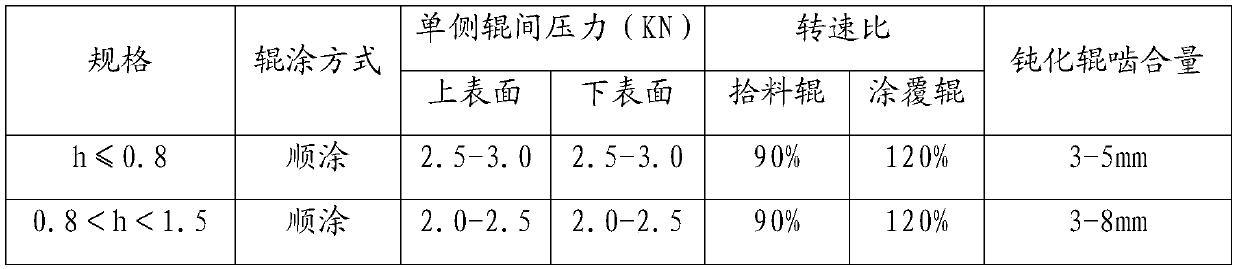

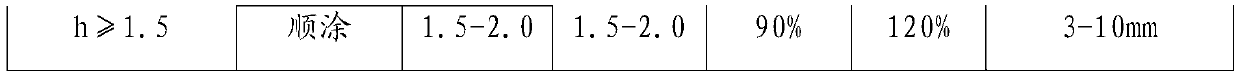

[0036] Clean and replace the working tank in the roller coating equipment first; then empty the passivation solution in the working tank into the working tank in the roller coating equipment; then obtain the temperature of the combustion chamber and control the temperature of the combustion chamber at 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com