Device and method for heating materials based on high-power laser

A high-power laser, heating material technology, applied in the field of material heating, can solve the problems of lack of temperature measurement and temperature control, inaccurate temperature measurement results, easy damage to temperature measurement components, etc., to simplify the experimental operation process, shorten the experimental operation time, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

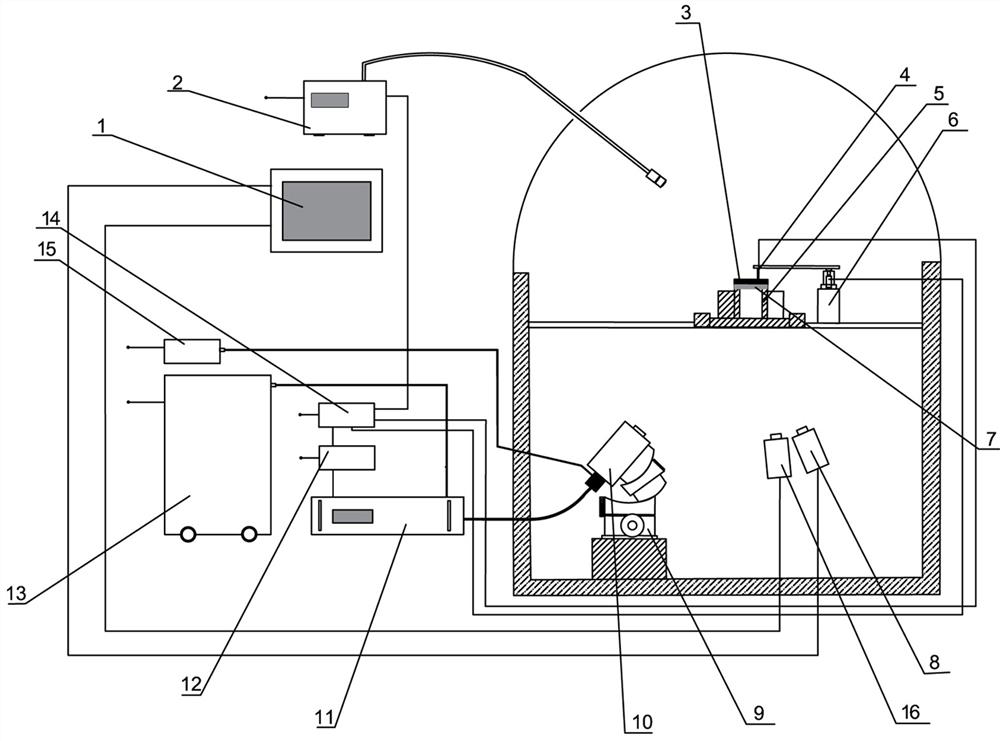

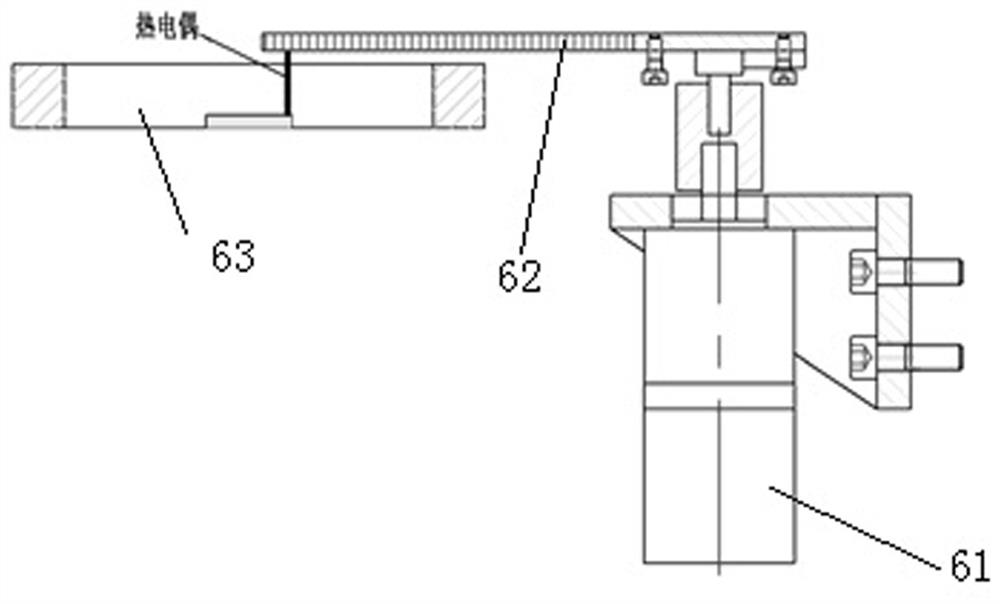

[0030] like Figure 1~2The shown device for heating materials based on high-power lasers includes a laser heating mechanism and a temperature measurement and temperature control mechanism; the laser heating mechanism includes a heating source assembly, a sample support assembly and a chiller 13, and the sample support assembly is composed of a sample and a water cooler 13. The switchable sample stage for placing the sample is composed of a sample support table 5 and a radiation transducer plate 7. The switchable sample stage directly places the sample when heating the high absorptivity sample. On the sample support platform 5; when heating the low absorptivity sample, place the sample on the radiation transducer plate 7 and then on the sample support platform 5. The radiation transducer plate 7 is a thin sheet made of high-temperature ceramics with high thermal conductivity. Structure; the heating source assembly includes a pulse drive power supply 12, a laser 11, a beam shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com