A b-doped nisi/n-si photoanode and its preparation method and application

A photoanode, n-si technology, which is applied in the field of photoelectrochemistry, can solve the problems of blocking photogenerated charges, low photocurrent density, and reducing the performance of photoanode, and achieves the effect of avoiding the blocking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

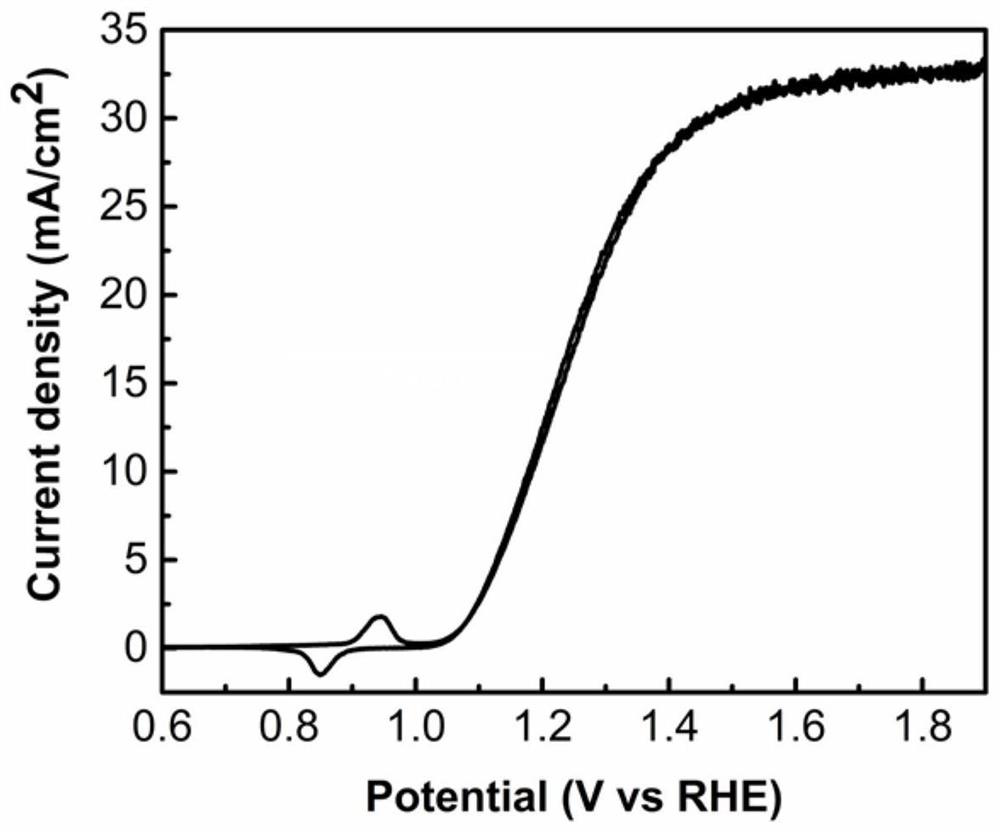

[0039] This embodiment provides a method for preparing a NiSi / n-Si photoanode, the specific method is:

[0040] (1) The p-doped n-type silicon wafer with a resistivity of 1-10Ω·cm is cleaned by a standard RCA method. Soak the cleaned silicon wafer in 10% dilute HF solution for 10 seconds to remove the surface oxide layer. The silicon wafer from which the surface oxide layer has been removed is immediately put into a magnetron sputtering chamber, and a Ni film with a thickness of 7 nm is deposited on it by magnetron sputtering to obtain a Ni / n-Si structure.

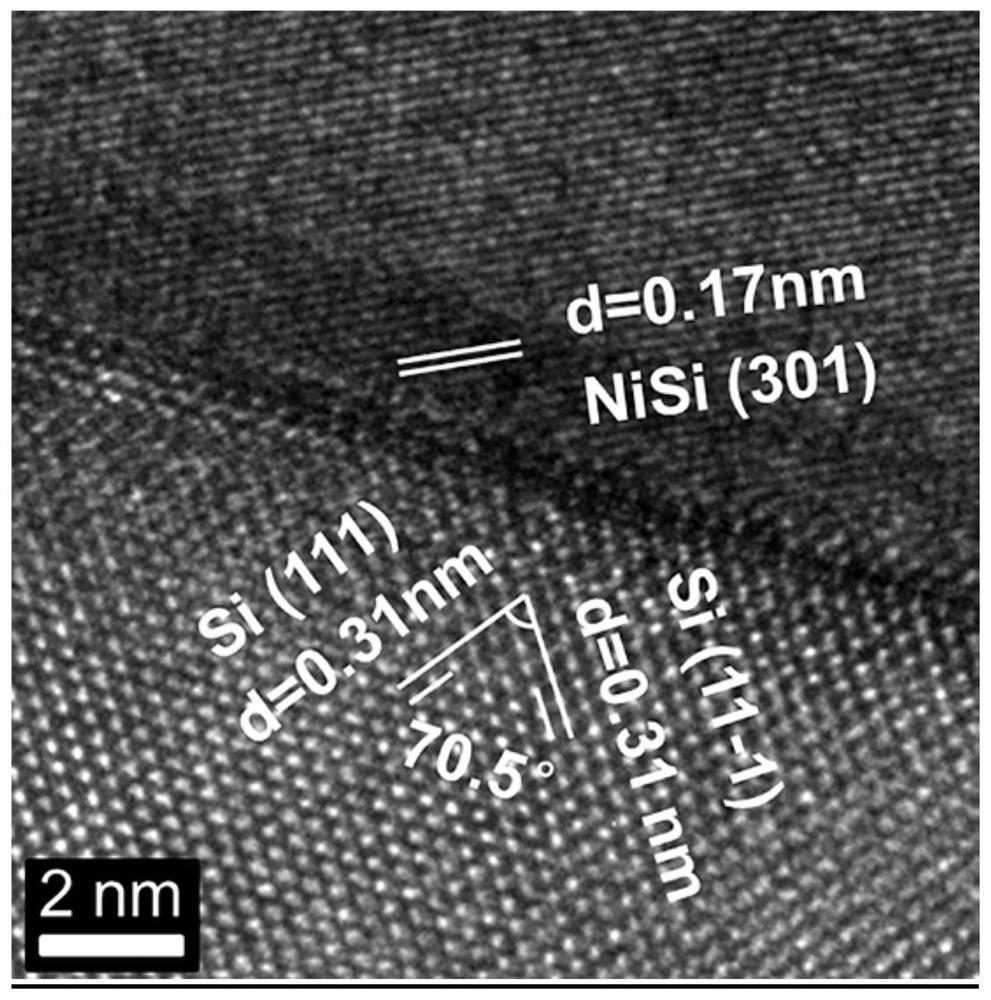

[0041] (2) Put the Ni / n-Si structure obtained in step (1) into a rapid heat treatment furnace, 2 Under atmosphere, rapid heat treatment at 500° C. for 30 seconds to obtain a NiSi / n-Si structure.

[0042] (3) Put the NiSi / n-Si structure obtained in step (2) into an ion implanter for ion implantation, the implanted ions are boron ions, and the implantation dose is 1×10 15 -5×10 15 cm -2 .

[0043] (4) Put the NiSi / n-Si...

Embodiment 2

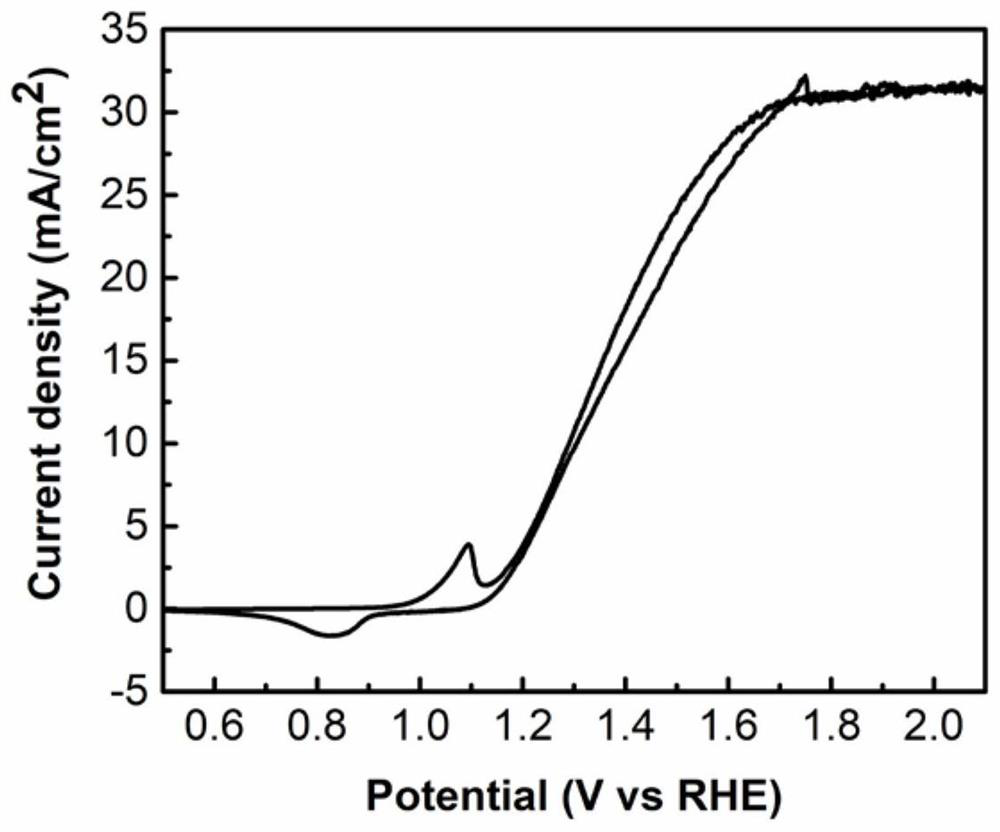

[0049] This embodiment provides a method for preparing a NiSi / n-Si photoanode, the specific method is:

[0050] (1) The p-doped n-type silicon wafer with a resistivity of 1-10Ω·cm is cleaned by a standard RCA method. Soak the cleaned silicon wafer in 10% dilute HF solution for 10 seconds to remove the surface oxide layer. The silicon wafer from which the surface oxide layer has been removed is immediately put into a magnetron sputtering chamber, and a Ni film with a thickness of 7 nm is deposited on it by magnetron sputtering to obtain a Ni / n-Si structure.

[0051] (2) Put the Ni / n-Si structure obtained in step (1) into a rapid heat treatment furnace, 2 Under atmosphere, rapid heat treatment at 500° C. for 30 seconds to obtain a NiSi / n-Si structure.

[0052] (3) Put the NiSi / n-Si structure obtained in step (2) into an ion implanter for ion implantation, the implanted ions are boron ions, and the implantation dose is 1×10 15 -5×10 15 cm -2 .

[0053] (4) Put the NiSi / n-Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com