Stamping equipment for improving material utilization rate and operation method thereof

A technology of stamping equipment and utilization rate, applied in the field of stamping equipment to improve the utilization rate of materials, can solve the problems of reduced working area, low utilization rate of raw materials, unstable raw materials, etc., and achieves high utilization rate, reduced manpower operation, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

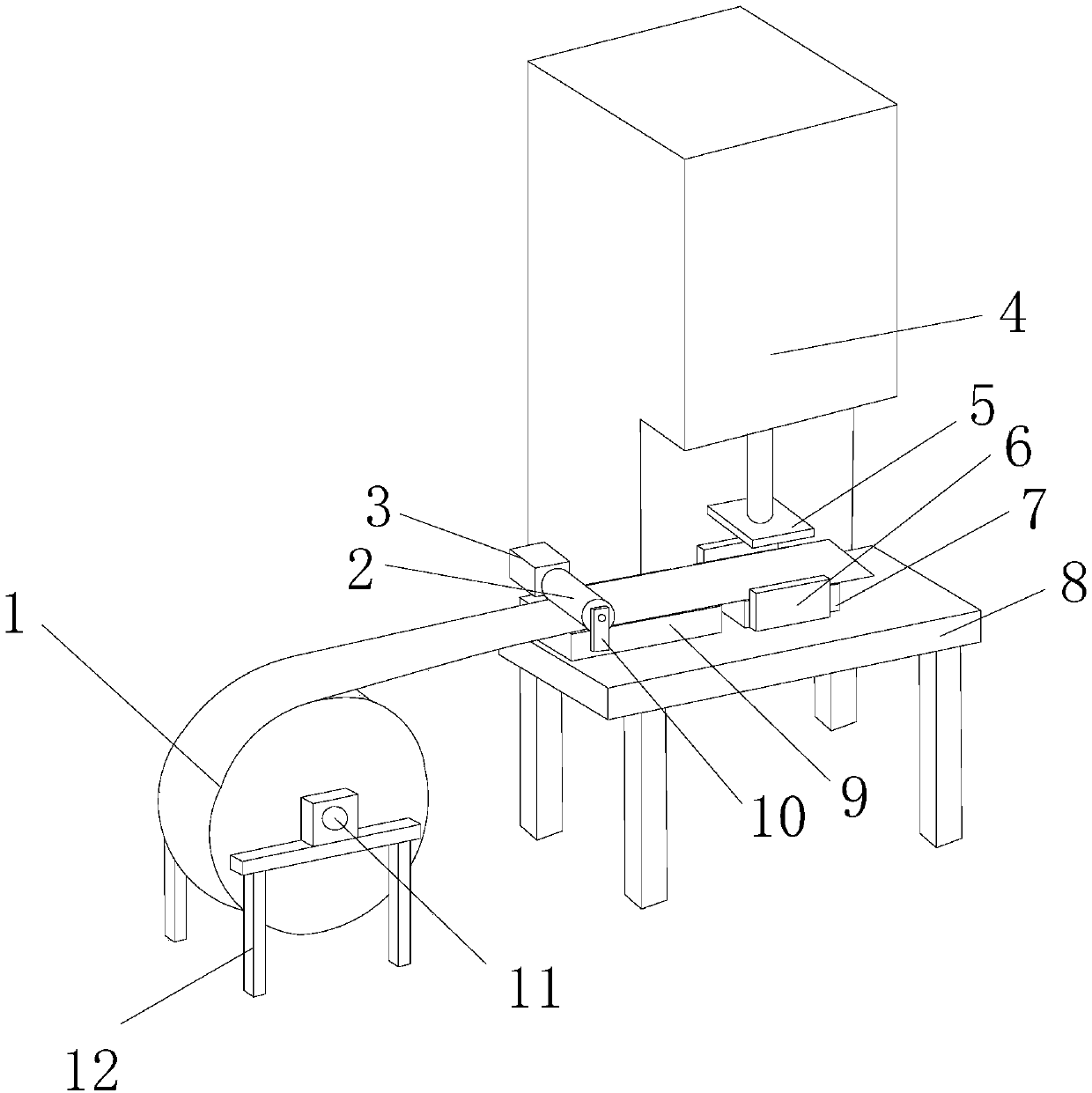

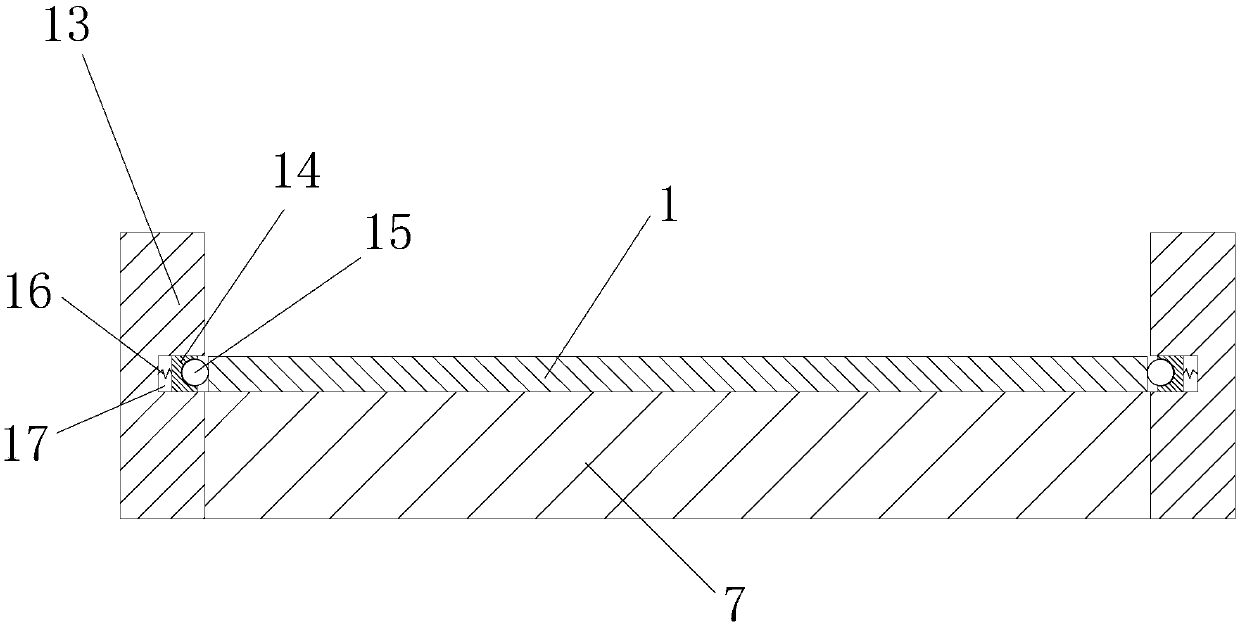

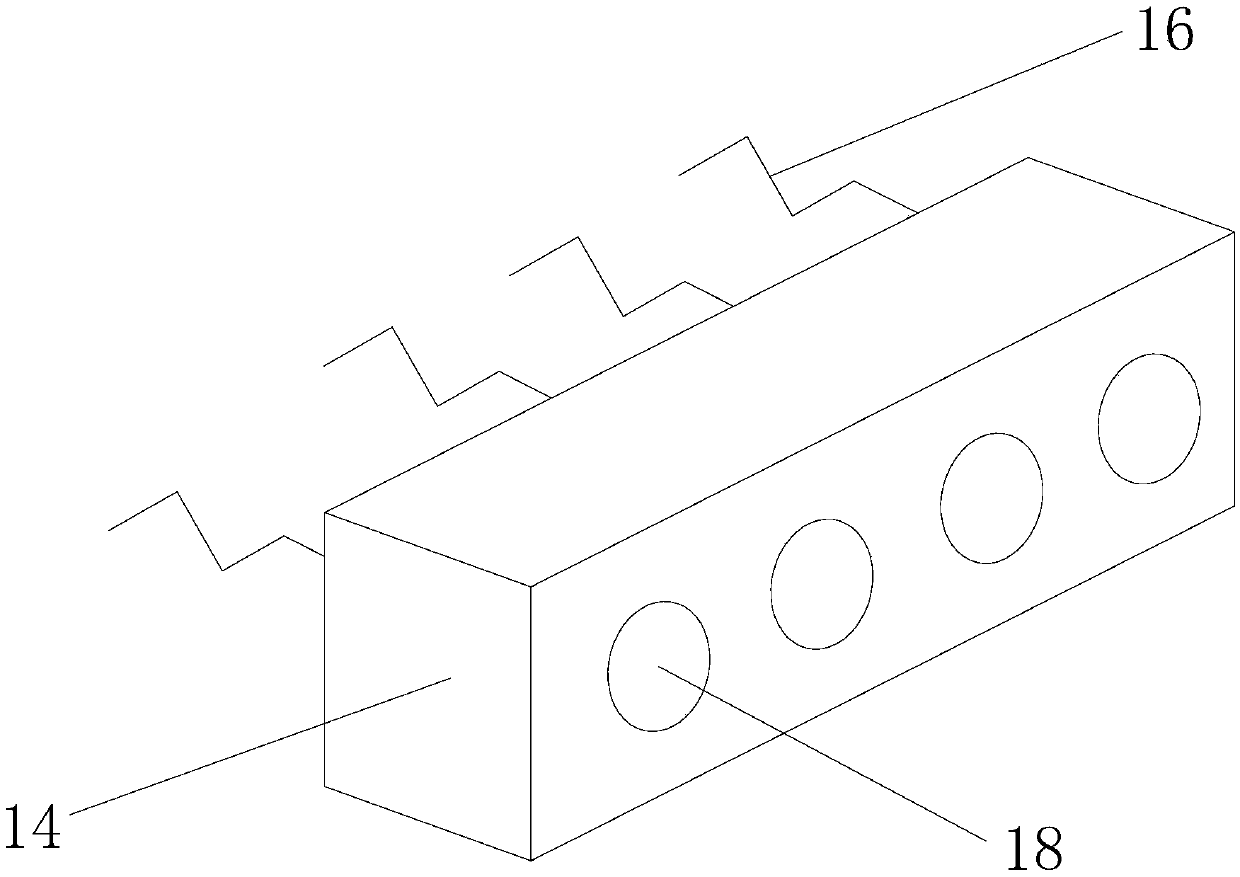

[0022] Such as figure 1 , 2 As shown in , 3, a stamping device for improving the utilization rate of materials includes a feeding part and a stamping part, the feeding part includes a coil rack 12, and the coil rack 12 is provided with a coil motor 11 for driving the coil 1 to rotate The coil material 1 is set on the output shaft of the coil material motor 11, and the coil material 1 can be driven to rotate when the coil material motor 11 is started. A support platform 9 is arranged on the side close to the coil material 1, a rolling shaft 2 is arranged above the support platform 9, a gap for the coil material 1 to pass is provided between the rolling shaft 2 and the support platform 9, and one side of the rolling shaft 2 A support plate 10 is hinged, and the support plate 10 is fixed on the workbench 8 and can support the rolling shaft 2. The other side of the rolling shaft 2 is connected with a driver 3 for driving the rolling shaft 2 to rotate. The finale shaft 2 rotates,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com