PET membrane punching mold forming by IMR and application method thereof

A mold and blanking technology, which is applied in the field of IMR forming PET film blanking molds, can solve the problems that it is difficult to achieve automatic production in edge trimming, cannot produce zero defects, and the injection molding cycle is short, so as to achieve simple mechanism and improve The effect of good product rate and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

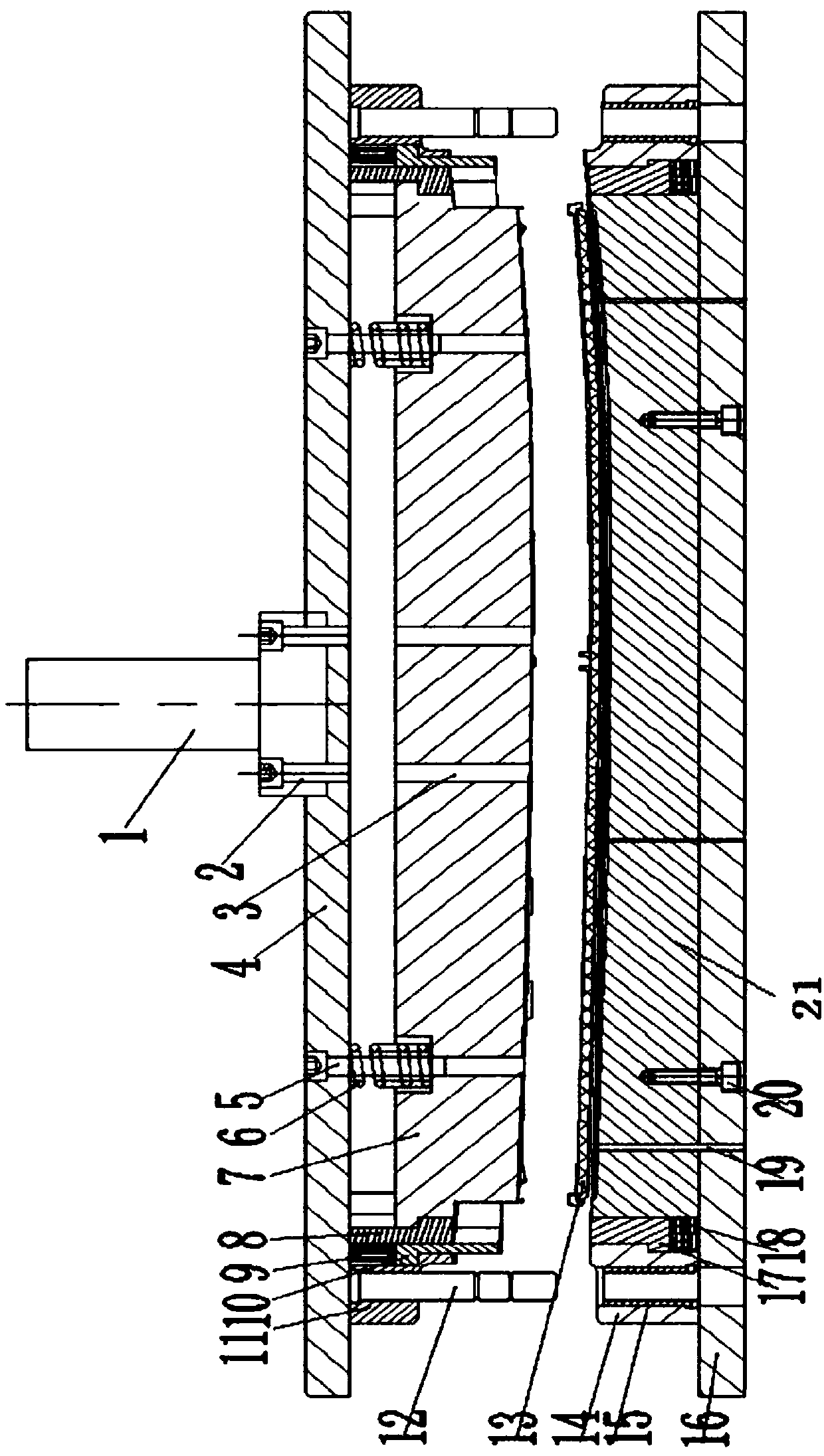

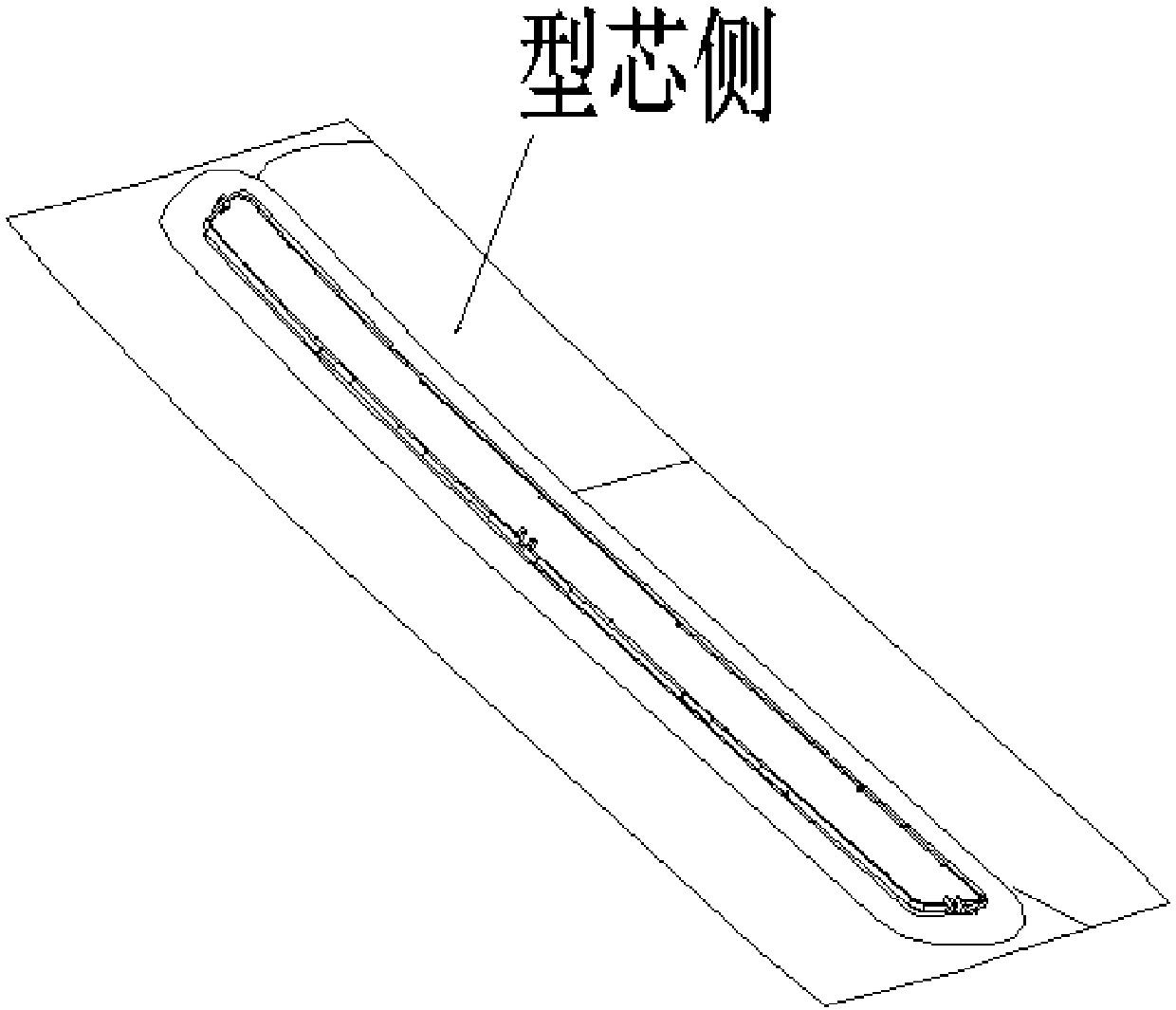

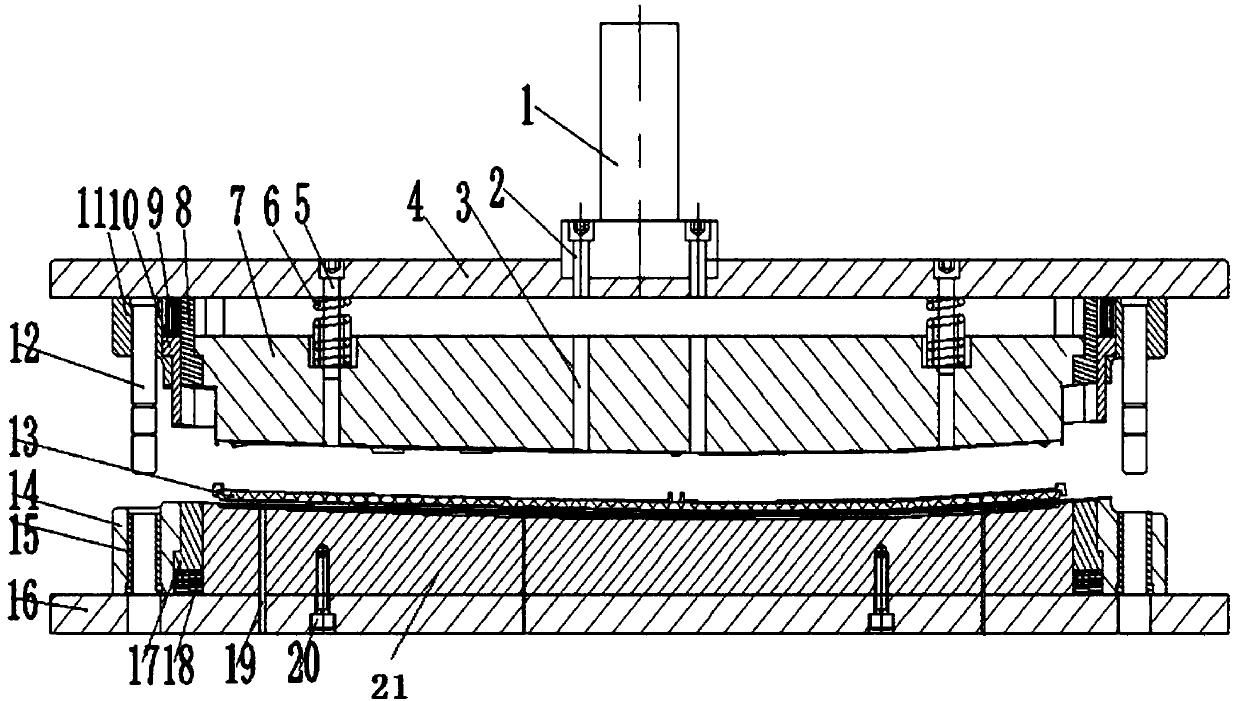

[0014] Figure 1-2 Shown is the relevant explanatory figure of the present invention; Figure 1-2 Shown, a kind of IMR forming PET diaphragm blanking die, the concrete embodiment is:

[0015] A punching die for IMR forming PET film, including die handle 1, die handle screw 2, vent hole 3, upper panel 4, guide pin 5, central pressing block spring 6, central pressing block 7, edge cutting die knife 8 , blankholder spring 9, blankholder ring 10, upper template 11, guide post 12, injection molded parts 13, lower template 14, guide sleeve 15, lower bottom plate 16, lower top edge ring 17, lower die 18, lower mold row Air hole 19, lower mold center insert screw 20, lower mold center insert 21.

[0016] The mold is divided into two parts, an upper mold and a lower mold.

[0017] The upper mold parts of the mold mainly include a mold handle 1, a mold handle screw 2, an air vent 3, an upper panel 4, a guide pin 5, a central pressing block spring 6, a central pressing block 7, a trim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com