Non-mechanical transmission driving method of bicycle and bicycle

A driving method, bicycle technology, applied in rider driving, vehicle components, transportation and packaging, etc., can solve the problems of complex mechanical transmission structure, bulky, inconvenient adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] A kind of non-mechanical transmission driving method of bicycle, refer to Image 6 As shown, the bicycle includes a frame 1, two wheels 2 arranged on the frame 1, two pedal units 3 arranged on the frame 1, a power generating mechanism ( not shown in the figure), and the drive motor 4 that drives the wheel 2 to rotate and is electrically connected to the generator;

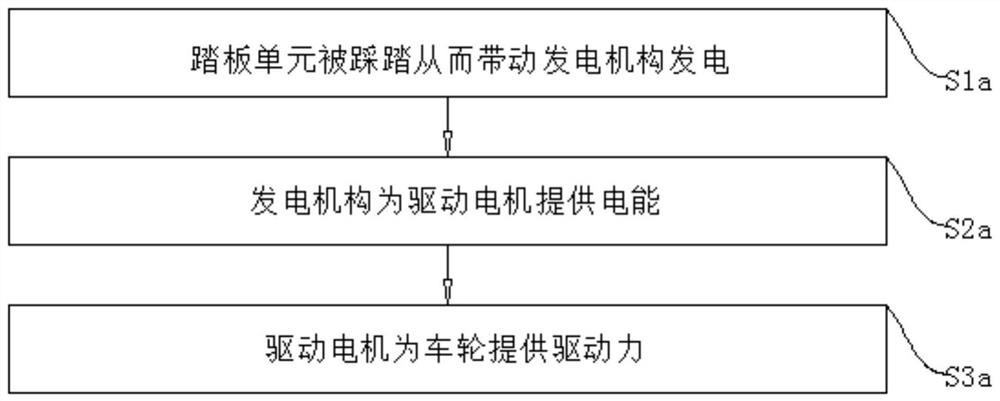

[0092] like figure 1 shown, including the following steps:

[0093] S1a The pedal unit is stepped on to drive the power generation mechanism to generate electricity; when the pedal unit is stepped on, the pedal unit can either rotate or move up and down; through the mechanical transmission of the transmission mechanism, the pedal unit drives the power generation mechanism to generate electricity;

[0094] S2a generating mechanism provides electric energy for driving motor;

[0095] The S3a drive motor provides driving force for the wheels.

[0096] To sum up: the above-mentioned driving method converts t...

Embodiment 2

[0098] This embodiment also provides a non-mechanical transmission driving method for a bicycle. The structure and driving steps of the bicycle are roughly the same as those in Embodiment 1, except that:

[0099] refer to Image 6 As shown, the bicycle also includes a controller that rotates the rotating shaft 5 provided on the frame 1, and a rotating shaft rotation information acquisition device (such as a gyroscope, magnetic encoder or generator);

[0100] like figure 2 As shown, the following steps are specifically included (the following step numbers are only used for identification, and are not used to limit the specific order):

[0101] The S1b pedal unit is stepped on to drive the shaft to rotate;

[0102] The rotating shaft of S2b drives the generating mechanism to generate electricity;

[0103] S3b The controller obtains a first speed ratio between the speed of the rotating shaft and the speed of the wheel;

[0104] The S4b controller obtains the rotational spee...

Embodiment 3

[0110] This embodiment also provides a non-mechanical transmission driving method for a bicycle. The structure and driving steps of the bicycle are roughly the same as those in Embodiment 1, except that:

[0111] The bicycle also includes a controller that rotates the rotating shaft arranged on the frame, and a rotating shaft rotation information acquisition device (such as a gyroscope, a magnetic encoder or a power generator) that is connected to the controller (either electrically or wirelessly). device);

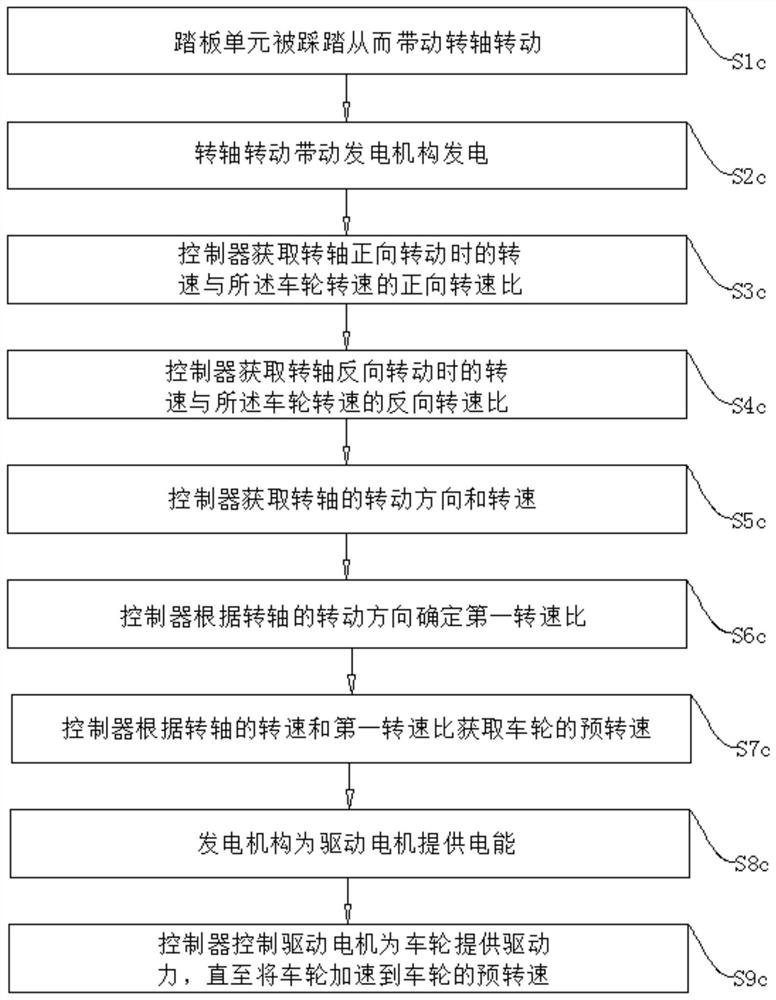

[0112] like image 3 As shown, the following steps are specifically included (the following step numbers are only used for identification, and are not used to limit the specific order):

[0113] The S1c pedal unit is stepped on to drive the shaft to rotate;

[0114] The rotating shaft of S2c drives the generating mechanism to generate electricity;

[0115] The S3c controller obtains the forward speed ratio of the speed when the rotating shaft rotates in the forward dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com