Penetrative-assembling method for compact type roller bearing structure motor

A kind of rolling bearing and compact technology, which is applied in the field of wearing and fitting of motors with compact rolling bearing structure, can solve the problems of not being able to use the fitting method, and not allowing the load-bearing to be shelved, so as to achieve the effect of avoiding load-bearing and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

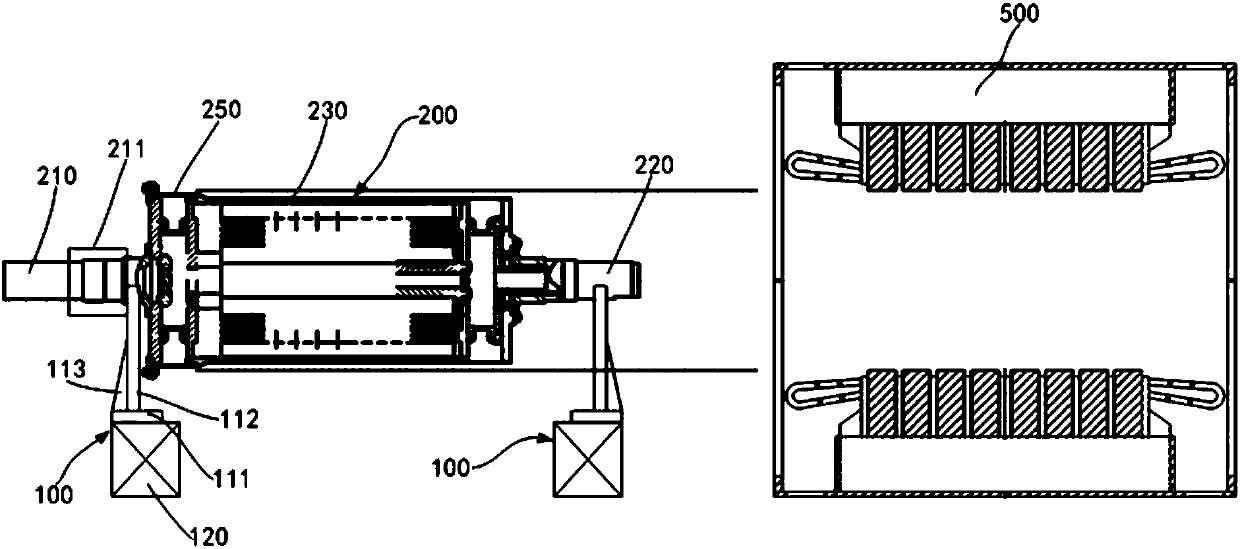

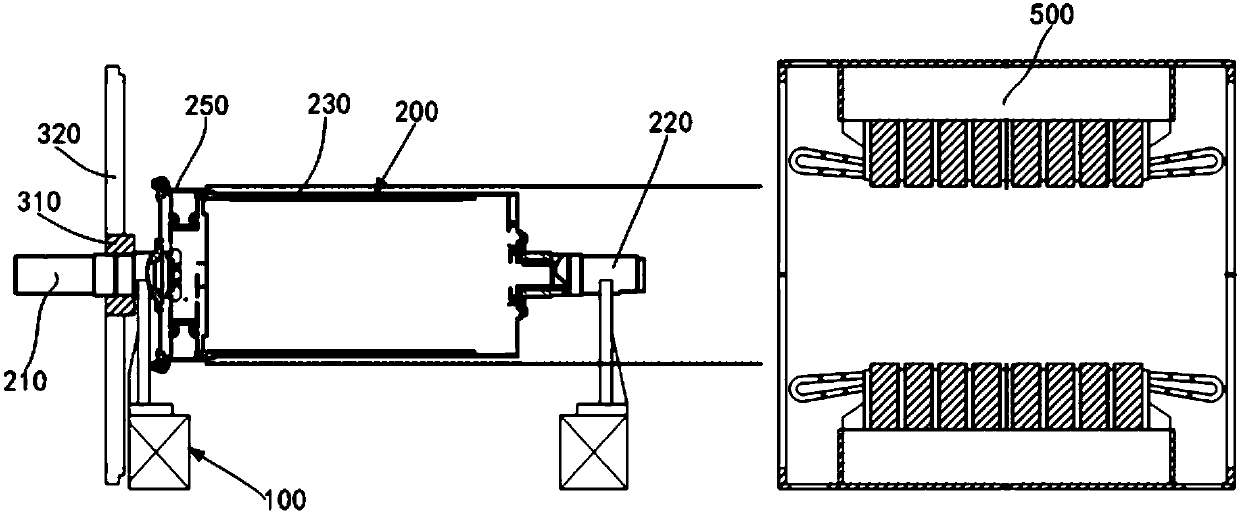

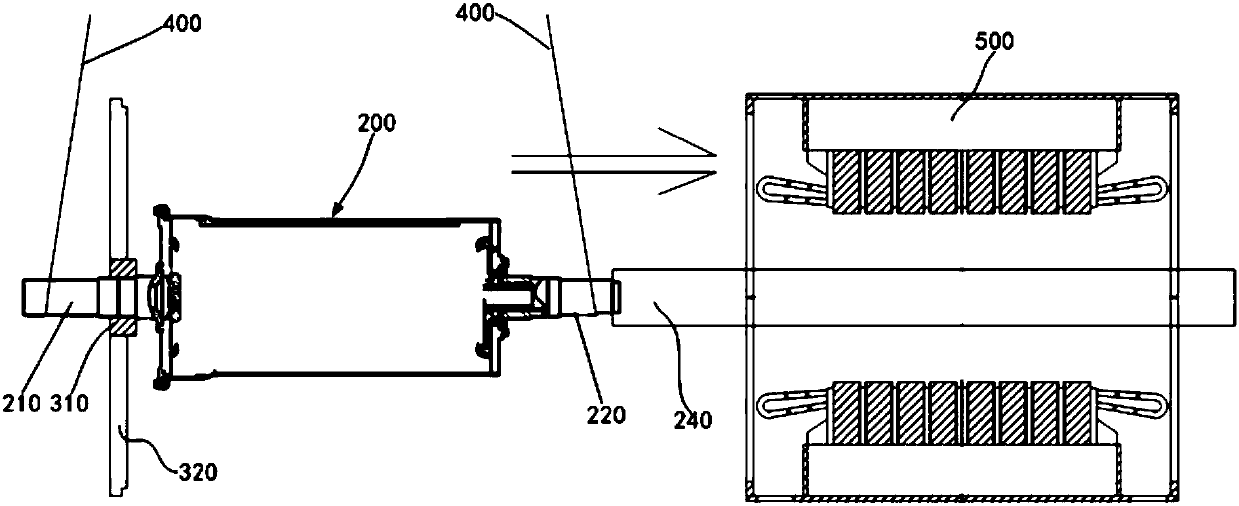

[0022] A method for mounting a motor with a compact rolling bearing structure, comprising:

[0023] One, such as figure 1 As shown, the shaft extension end 210 and the non-shaft extension end 220 of the motor rotor 200 are rested on the support frame 100 located on both sides of the axial direction, and the support frame 100 on the shaft extension end side is located at the installation position of the rotor body 230 and the bearing and the end cover. Between 211.

[0024] Wherein, the support frame 100 includes a frame body 110 and a spacer 120 for cushioning under the frame body 110, such as Figure 5 As shown, the frame body 110 includes a base plate 111 and a support plate 112, the base plate 111 is arranged horizontally, the support plate 112 is vertically fixed to the base plate 111, and two reinforcing plates in a right triangle shape are connected between the front and rear sides of the support plate 112 and the base plate 111. Plate 113, two reinforcement plates 113...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com